3

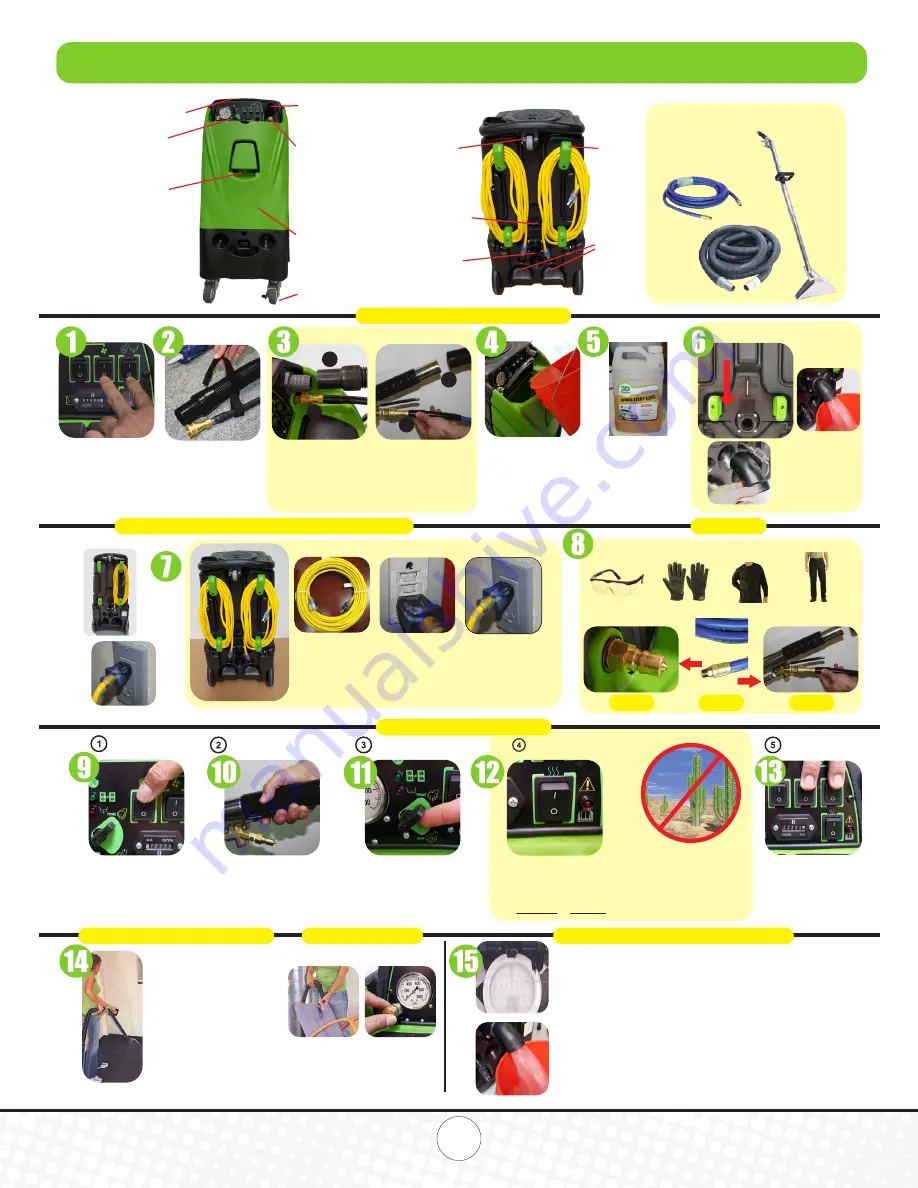

12-gallon QUICK START GUIDE

Plug into grounded outlets,

No GFI outlet.

Assemble your vacuum

& solution hose. Small loop

goes over small hose velcro

over hose. Large 5 straps,

one every five feet.

Make sure all

switches are in

the OFF position.

1. Connect your hose to vacuum

2. Solution hose

3. Push back locking sleeve, insert brass post,

let locking sleeve cover spring back covering

retaining balls

4. Push vacuum hose & cuff over 1.5” hose barb

Quick Start Machine Preparation

Recovery tank access

Vacuum

hose

connection

Hose

solution

connect

Indestructible

molded

body

Control panel

Optional wand holder

Locking caster

Dump valve

Roller

wheel

Motor

Cool-air

Intake

Cord

wrap

Dump

valve

extender

Turn pump on

Pump test, prime machine

Prime 300 & 500 PSI

Vacuum motor

Many surfaces are hot, wear protective

clothing

Switches

Hoses & Straps

Vacuum & Solution hose

Power Single Cord Machine

No Power Dual Cord Machine

Pull trigger until liquid

sprays from spray jets.

Pump and heater are now primed

with water or cleaning solution.

For 500 PSI units a

prime valve is located on

the front panel.

A. turn up to prime.

B. Spray for 30 seconds

C. Turn valve down to run position

Now that the pump is

primed with water or

cleaning solution.

Turn heater on

for 5-minutes to Pre-Heat.

CAUTION

Never run heater

DRY or without

liquid. Throughout

the machine and

hose system.

Failure to do so,

will damage the heater.

Wear eye

protection

Wear gloves

Wear

long sle

e

ves

Wear

long pants

Complete hose & wand kit

(25 ft. vac & solution hoses and wand)

Turn on both

vacuums motors.

Carpet Cleaning and wand use

Upholstery

Disposal of Water & You’re Finished

Start Sequence 1,2,3,4,5

HOT

HOT

HOT

1

3

2

4

Pour liquid into front

cavity. (For best results

use 100° water) Do not

use more chemical than

directed. Over use

of chemical clogs

jets, brass and reducing

heater performance.

Stores into slot

below dump valve.

Cleaning liquids

Dump valve

extender

Dump valve closed

position

Electrical Connection

Heater Pre-Heat

When doing upholstery it’s

important not to overwet, test

on an unseen area and

allow to dry prior to starting.

Use liquid detergents

only. Powder clogs

pumps + filters

DRY

Reduce pressure to 100PSI

Liquids detergent

only

1 Cord Extractor | 2 Cord Extractor

When You’re finished

1. Take the vacuum hose off the wand

and put it into the front tank and

vacuum out the remaining cleaning

chemicals to the recovery tank, dump

the water into a bucket or toilet.

2. Run clean water (warm if possible)

throughout the machine to remove

cleaning chemicals from coating

internal hoses/jets.

3. Unplug the equipment, wipe it down

with clean cloth and soap and return

it to a safe storage area.

Disposing of dirty water

1. Unplug the extractor and back it

over a toilet or bucket

2. Slowly pull the dump-valve up

and dispose of the water to

the sewer system.

3. Remember to close it when done.

4. Never dispose of liquids on to

the soil, outdooor gutter or into

the environment.

HOT!

After start sequence above

1. Start in the far corner and

plan your exit.

2. Do a series of 4’x6’ area

spraying forward and

extracting back. Overlap

by 2” on each stroke.

3. After your 4’x6’ area is done

go over it again vacuuming

only at a slow pace to

remove any missed liquids

to improve drying.

GFI’s 1st plug in one cord.

2nd Cord must be on a seperate circuit. A light and

sound pulse will activate when you plug into a 2nd

circuit. If you do not hear a pulse tone move cord to other

outet until you obtain a 2nd pulse. Pump will not run

unless 2nd circuit light is on, no GFI outlets.