WRANGLER 20 E

IMPORTANT SAFETY INSTRUCTIONS

READ AND UNDERSTAND ALL INSTRUCTIONS

BEFORE OPERATING OR SERVICING MACHINE

DANGER

!

Failure to Observe These Instructions Can Cause Personal Injury

to Machine Operator, By-standers or Possible Machine Damage.

* NEVER

attempt to operate this machine unless you have been trained in its operation.

* NEVER

allow an untrained person to operate this machine.

*

Use this machine

ONLY

as described in this manual.

* NEVER

attempt to operate this machine if it is not working properly or has been damaged in any manner.

* NEVER

disconnect or modify any switch or safety device (circuit breaker) on this machine.

* ALWAYS

operate this machine from the rear control panel, not from the side.

* NEVER

drop or insert any object into any machine opening.

* ALWAYS

keep face, fingers, hair or any body part, or loose clothing away from any machine opening or

moving part (revolving brush, pad driver, or vacuum motor).

* NEVER

operate this machine with any air opening blocked. Keep all air openings free of dust, lint, hair etc.

* NEVER

spray this machine with water or any liquids.

* NEVER

allow the vacuum motor or battery charging plug to get wet. The vacuum motor and battery

charging plug will short out if wet.

* NEVER

operate this machine in an explosive atmosphere (grain dust, flammable liquids or fumes).

* NEVER

use flammable liquids (gas, kerosene, solvents or thinners) to clean floor.

* ALWAYS

turn the brush switch

OFF

when attaching pads or brushes.

* NEVER

operate this machine with the splash skirt removed.

* NEVER

leave this machine unattended.

* ALWAYS

store this machine indoors in a dry, cool area.

PERSONAL INJURY AND PROPERTY DAMAGE FROM THIS MACHINE OVERTURNING, BATTERIES

FALLING OUT OF THE MACHINE OR BATTERIES LEAKING ACID CAN OCCUR IF YOU DO NOT FOLLOW

THESE PRECAUTIONS:

* ALWAYS

be sure that the ramp is secured to the vehicle before attempting to load / unload.

* ALWAYS

use extreme caution when operating this machine on a ramp or loading / unloading this

machine into or out of a truck. Use extreme caution if the ramp is wet, oily or covered with cleaning

chemicals.

* NEVER

turn this machine on an ramp or incline.

* NEVER

stop this machine on a ramp or incline.

* NEVER

attempt to climb a grade or operate this machine on a ramp or incline of more than

20 degrees.

* NEVER

park or store this machine near a dock, on ramps, near a furnace, boiler, open flame, or other

high heat source.

* NEVER

allow this machine to freeze.

* NEVER

store any items on this machine.

ALL

repair service must be performed by an NSS authorized distributor/service station. Use only NSS

original equipment parts.

SAVE THESE INSTRUCTIONS

Summary of Contents for WRANGLER 20 E

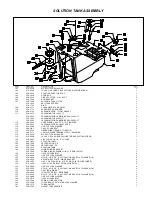

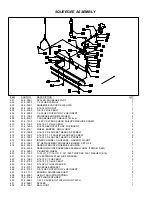

Page 5: ...WHEEL AND VALVE ASSEMBLY...

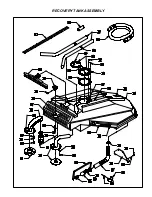

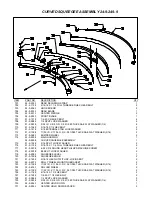

Page 7: ...RECOVERY TANK ASSEMBLY...

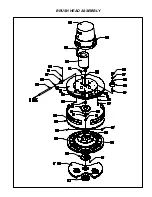

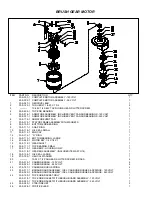

Page 11: ...BRUSH HEAD ASSEMBLY...