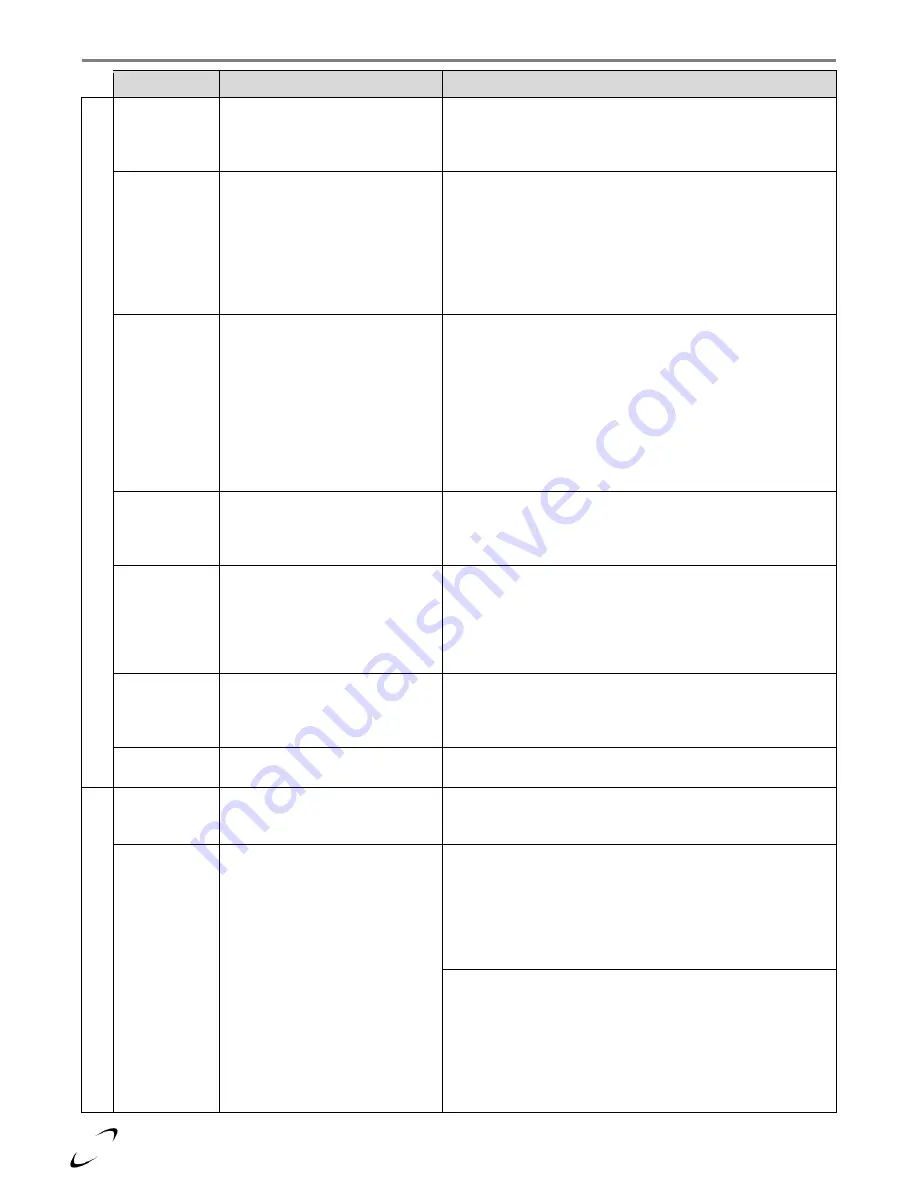

Installation and Operation Instructions Matrix

68

Symptom

Detected Problem

Solution

F

a

n Co

ntr

o

l (

B

lue F

a

ce

)

AL1

Communication Error with HRV

1.

Check wiring connections between HRV and Fan

Controller.

2.

Check door switch on HRV.

3.

Cycle power to appliance; contact NTI.

AL2

Plenum Temperature Limit of

160ºF Exceeded

1.

If plenum is hot, check operation of blower fan; contact

NTI.

2.

If plenum is not hot, check plenum sensor and wiring for

shorts or damage.

3.

Remove plenum sensor, PSO should be displayed, if so

replace plenum sensor, if not inspect wiring from

Terminal Strip to Fan Control. Replace Fan Control if

necessary.

AL5

“DHW Time-Out”

The Control has locked out DHW

due to the demand lasting longer

than 2.5 hours.

1.

Reset the AL5 error by resetting the power or cycling the

DHW call. Check for proper operation of the DHW call.

2.

Matrix units are provided with an integrated DHW flow

meter, if the control is registering a flow rate when the

water is turned off; disconnect the electrical lead to the

flow meter. If the indicated flow rate drops to 0, replace

flow meter, if not, replace fan controller.

3.

Ensure nothing is connected to the FS terminal of the

terminal strip (unless using a DHW tank aqua-stat to

trigger a demand – check operation of aqua-stat).

AL7

‘Boiler Control Error’

Fan controller has failed to

receive run status from Boiler

Control.

1.

Check for error code on Boiler Control.

2.

Check control wiring from Boiler Control to Fan Control

(Pins 17 and 18 on Fan Control – See wiring schematic in

Section 16.0).

AL8

(& Blower

Off)

‘Furnace Blower Error’

Blower has failed to meet a

minimum speed.

1.

Check for 120V to blower; ensure door switches are

making the circuit.

2.

Check wiring from Pin 6 at Fan Control (white wire) to

Pin 15 at blower motor.

3.

Check for 24VDC at blower Pin 15, if present replace

blower, if not replace Fan Control.

AL8

(& Blower

On)

‘Furnace Blower Error’

Control has failed to sense that

the blower has reached a

minimum speed.

1.

Check wiring from Pin 5 at Fan Control (black wire), to

Pin 16 at blower motor.

2.

Check for 3-5VDC at blower Pin 16, if present replace

blower, if not replace Fan Control.

F3.5

Flashing

Lack of 24 V at fan controller

1.

Check/Replace 2A fuse – blown fuse indicates 24V

supply shorted to ground, or excessive load.

F

enwa

l Ig

nitio

n Co

ntr

o

l

Two

Flashes on

Fenwal

The Fenwal controller thinks that

there is a flame prior to ignition.

Indicates Ignition Lockout.

If the combustion sequence is normal, and there is no flame

prior to ignition, the Fenwal control is defective, and must be

replaced.

Three

Flashes on

Fenwal

“Ignition Lockout”

If the condensate drain gets blocked, the boiler will become

flooded and terminate operation as the flame rod becomes

immersed. This will damage the flame probe. To correct, free

the drain blockage, and permanently prevent it from

reoccurring. Remove and dry off the probe. Reinstall the

probe and try for ignition, if it fails to stay lit, leave the fan

run for up to three hours to dry out the insulation and probe.

1.

Reset Boiler so it will attempt to ignite.

2.

Check for proper operation of ignition components.

Make sure igniter glows and gas valve opens.

3.

Check for proper line pressure at gas valve when it opens.

4.

If boiler lights check for flame signal between FC1 and

FC2 on Fenwal control (If lower than 1.2 DC µAmps see

“Boiler will not stay lit”).

5.

Check combustion properties.