,,

16

Press

to start the

heating cycle and stand at a

safe distance.

There is a 5 second

countdown before the

cycle starts.

When the preset

temperature has been

reached, the heater will

hold that temperature.

Press

to stop the

heating cycle.

The induction heater will

now demagnetize.

After it will return to the

first screen.

1. PREPARATION

2. HEATING PROCESS

3. COMPLETION

Press

+

or

–

to change the

temperature (max. 240°C).

Press

+

or

–

to change

the

∆

temperature (min. 20°C).

To change the

temperature, press

.

To change

the

∆

temperature,

press

35

.

Otherwise, proceed

to step 2.

Press

P

when the temperature is

set.

Press

P

when the temperature

is set.

35

35

35

TEMPERATURE MODE, TWO SENSORS

Alternatively, to start the

heating process, press the start

button on the remote.

OPTIONAL

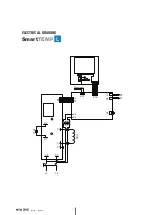

Summary of Contents for SmartTEMP L

Page 1: ...With You www ntn snr com USER MANUAL SmartTEMP S M L XL XL Pivot XXL XXXL...

Page 4: ...4...

Page 31: ...ELECTRICAL DRAWING Start Stop SmartTEMP XL XL Pivot 31...

Page 32: ...ELECTRICAL DRAWING Start Stop SmartTEMP XXL 32...

Page 33: ...ELECTRICAL DRAWING Start Stop SmartTEMP XXXL No contact input No contact input 33...

Page 35: ...NOTES 35...