- 11 -

[2] Caution in attaching and detaching leaf spring

When attaching and detaching the leaf spring, be sure to complete one unit before moving to the next

unit. Do not loosen all the units at the same time.

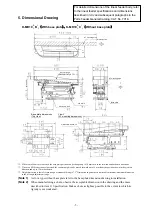

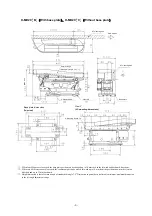

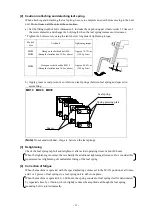

a) Set the fitting depth of bolts (dimension L includes the depth on upper vibrator side) 1.5 times of

the screw diameter, and change the bolt length when the leaf spring increases or decreases.

* Tighten the bolt securely, using the table below for guide of tightening torque.

Model/

Size

Used bolt

Tightening torque

MD10

MD20

Hexagon socket head bolt M6

(Strength classification 10.9 or above)

Approx 14.7 N

x

m

(150 kg f

x

cm)

MD30

Hexagon socket head bolt M10

(Strength classification 10.9 or above)

Approx 68.6 N

x

m

(700 kg f

x

cm)

L

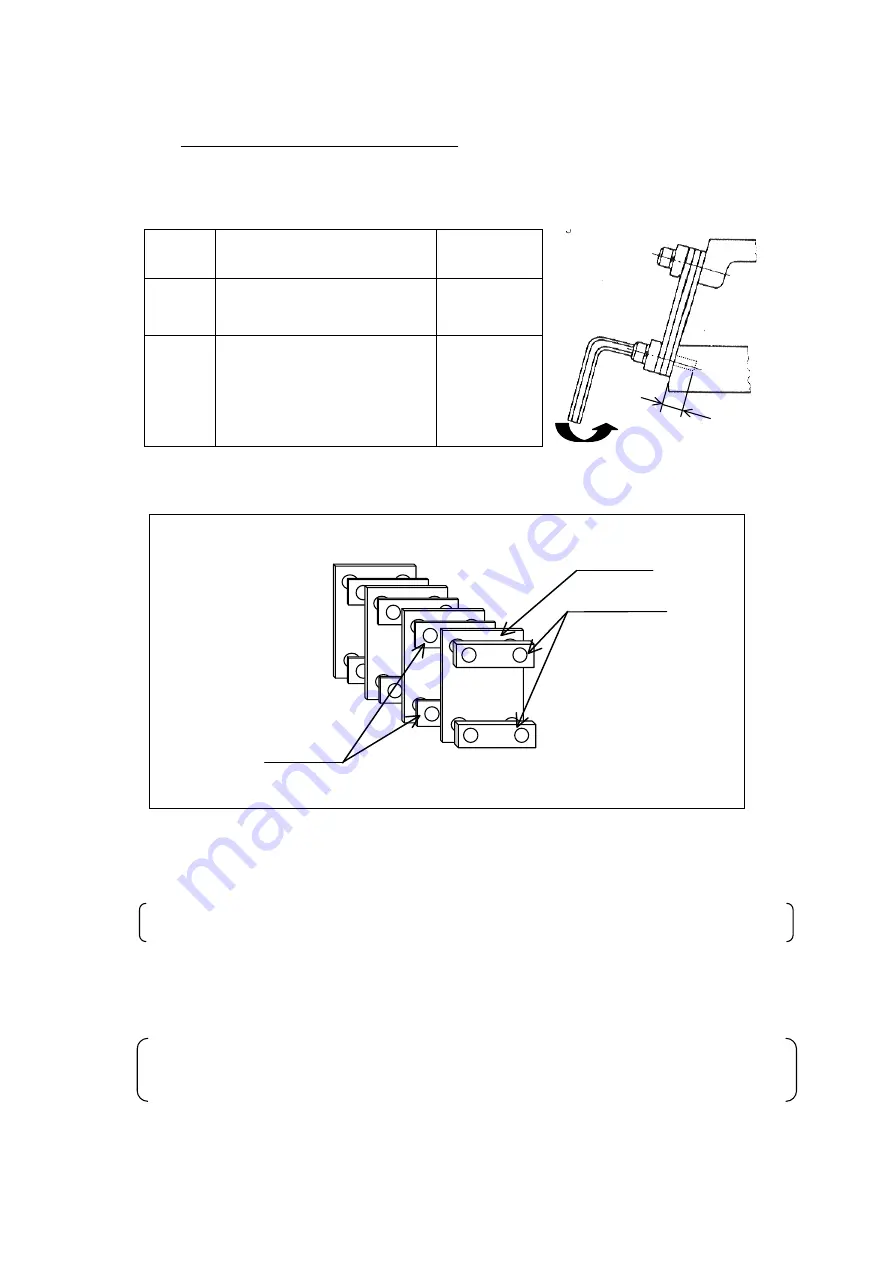

b) Apply grease or rust preventive oil between leaf springs (between leaf spring and spacer) in

assembling.

MD10 MD20 MD30

(Note)

Do not sandwich dust, chip, etc. between the leaf springs.

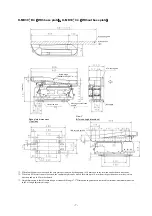

[3] Retightening

Check the leaf spring tap bolt and retighten it after actual operating time of about 40 hours.

When the tightening is normal, there is hardly the additional tightening allowance. But, consider this

requirement as retightening of comfortable fitting of the leaf spring.

[4] Correction of fatigue

When the machine is operated with the speed adjusting volume set to the MAX. position at all times,

add 1 or 2 pieces of leaf springs to a leaf spring unit in either one place.

When the machine is operated 40 - 100 hours, the spring constant of leaf spring itself is deteriorated

by repeated stress by vibration, which slightly reduces the amplitude, although the leaf spring

mounting bolt is jointed normally.

Leaf spring

Spacer

Spring pressing plate