Rev. December 19, 2008

Page 10 of 19

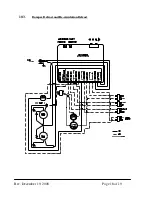

# 1 Frequency Setting - Set to ON (down) for 60 Hz service. This includes all of North America. Set to

OFF (up), for electrical grids using 50 Hz.

#2 Defrost Type - ON (down) is for damper/recirc. models. OFF (up) is for fan shut down defrost

models.

#3 Fan Selector - OFF (up) is for the NU075 machine only. All other models are set to ON (down).

#4 Arctic Mode Selector - for design temperatures of -30 0C (-22 F) and colder for Damper/recirc.

defrost machines, or design temperatures of –20 0C (-4 F) and colder for FSD defrost machines, set to

Off (up). Otherwise set to ON (down). When the machine is set to operate in arctic mode, the machine

will increase the amount of time spent in defrost.

Variable low-speed motor control:

For field adjustment of the low (continuous) ventilation rate, pushbutton switches S1 & S2 are used.

These are located on the bottom left of the board. S1 is labeled DEC (decrease) and S2 is labeled INC

(increase). Each push of S1 or S2 decreases or increases low speed by increments of 3%. Low speed is

set at 40% of high speed in the factory by default and cannot be lowered beyond this point. The

maximum low speed setting is approximately 70% of high speed. Settings are stored in the board’s

memory, eliminating the need to reset the speed after a power failure for instance.

Self-resetting fuse:

Field mis-wiring of timers or dehumidistats may cause the fuse to trip. If this happens, remove the

control wires and allow the fuse to reset. This may take a few minutes. Check your manual for proper

wiring connections.

Troubleshooting using the PCB light:

There is a small green light on the board located just below the DIP switches. This light will either be

solid or pulsing and is an indicator of machine status. It can be used to assist in troubleshooting

.

Machine State

Light Status

Machine has no power

Off

Power to the board, but main power switch is off

or the door switch is tripped

Two short pulses approximately every 5 seconds

Machine running normally in low speed

Pulsing – on for one second, off for one second

Machine running in high speed due to a call from

dehumidistat, timer, or defrost cycle

Solid

Defrost Cycles:

Fan Shutdown Defrost – On FSD machines, the temperature sensor is located in the fresh air stream

before the core. When this air is measured to be below freezing, a timed defrost cycle is initiated. The

fresh air fan motor is stopped for 4 minutes (both normal and arctic modes). The exhaust fan motor

continues to operate, drawing warm air from the building through the core. After 4 minutes, the fresh air

fan motor is started again and runs for 20 (normal mode) or 12 (arctic mode) minutes. This cycle is

repeated until the temperature of the exhaust air stream is measured to be above freezing.