Rev. December 19, 2008

Page 6 of 19

hoods to the HRV as short as possible to minimize airflow restrictions. Avoid sharp bends and stretch

out the inner lining of the flex duct as much as possible to reduce static pressure and maximize airflow.

For runs over 12’, increasing flex diameter 1” to next size up will reduce pressure drop in the duct.

2.3.1.1.

Locating the Weather Hoods

There should be a minimum of 6’ (feet) of separation between the fresh air and exhaust hoods. Supply

hoods should be a minimum of 18” (inches) above the ground level. Exhaust hoods should be at least 4

“(inches) above the ground level. Holes through the wall should be 1” larger than the collar on the

hood. Fresh air hoods must be 3’ away from any other appliance exhaust vent or furnace vent.

In addition ASHRAE Standard 62-99 recommends the following. Ventilation systems should be

designed to prevent the reintroduction of exhaust contaminants, condensation or freeze-ups and growth

of microorganisms. Make-up air inlets and exhaust air outlets shall be located to avoid contamination of

the makeup air. Contaminants from sources such as cooling towers, sanitary vents, vehicular exhaust,

and street traffic should be avoided.

2.4.

Mounting & Noise Control

For maximum efficiency, the HRV should be installed in a heated area. The HRV is designed to be hung

from the ceiling by way of the anti-vibration straps supplied. Avoid hanging the HRV directly below a

bedroom or other quiet area.

2.5.

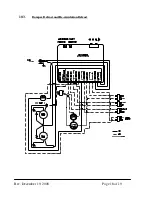

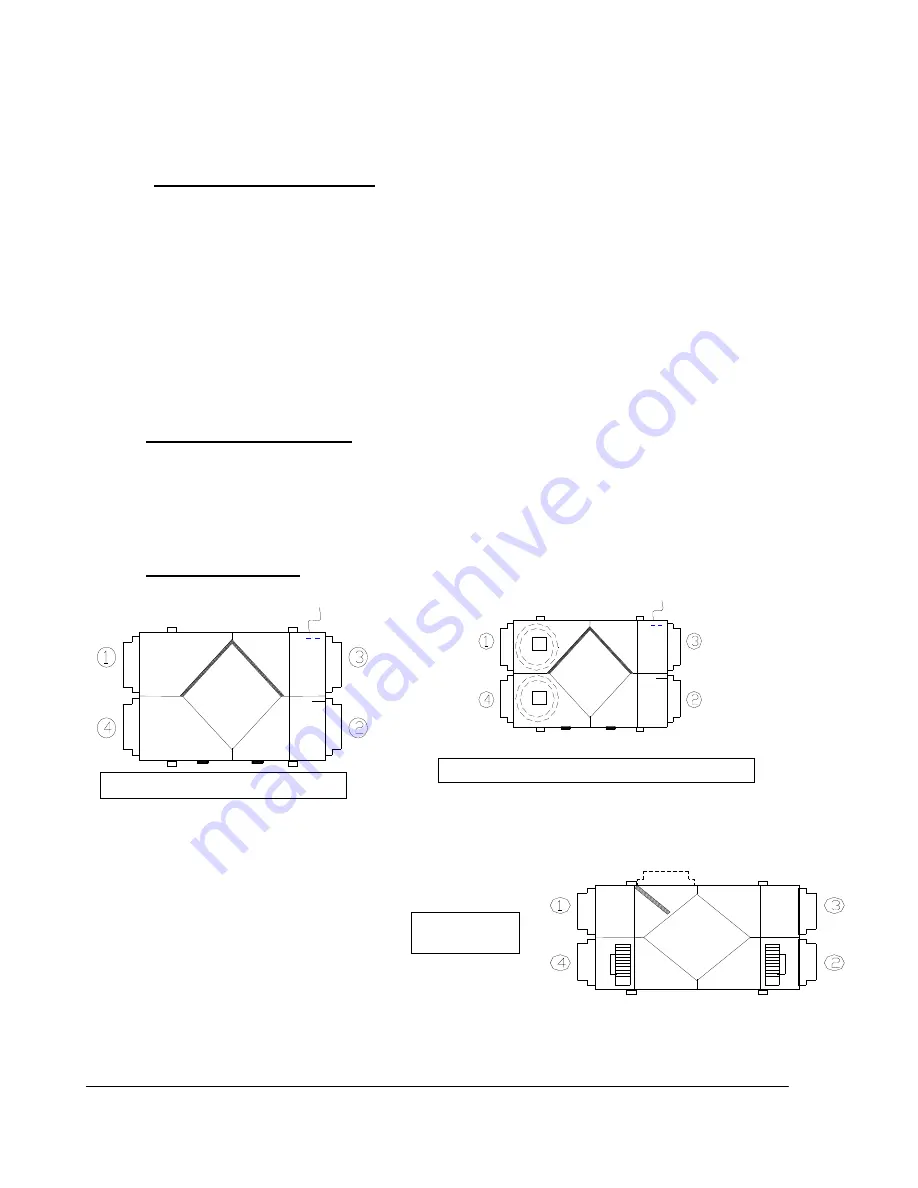

Port Configurations

1.

FROM OUTSIDE - Insulated flex pipe

2.

TO SPACE - Non insulated pipe

3.

FROM SPACE - Non insulated pipe

4.

TO OUTSIDE - Insulated flex pipe

5.

DEFROST IN (CEA18 ONLY)

6.

DEFROST OUT (CEA18 ONLY)

CEA15-R

CEA18-C

CEA20-D

5

6