NITESTAR MODELS NS-50 AND NS-60

The Nu-Metrics NITESTAR Vehicle Installed Distance Measuring

Instruments are available in two models; the NS-50 and the NS-

60. Both models are easy-to-use distance measuring instruments

(DMI) that facilitate land measurements from the convenience of

your automobile. The model NS-50 includes features required for

most basic surveys and applications.

The NS-60 includes all of the features of the NS-50 with the addi-

tion of a RS-232 Serial Port for connection of a serial printer, lap-

top computer, or GPS unit. With the RS-232 serial option and a

laptop computer, it is possible to conduct a complete highway

survey and then print directly to a 40 to 80 column serial printer.

DISTANCE MEASURING INSTRUMENT (DMI)

THEORY OF OPERATION

For electronic measurement of distance; a proximity sensor,

mechanical transmission sensor or electronic interface adapter is

used to provide speed pulses to the NITESTAR DMI for distance

measurements. How the DMI calculates distance is relatively

simple for each of the sensors.

The proximity sensor divides the vehicle tire into pie sections by

equally spaced targets attached to the rim. The spacing distance

between each target projects the proportional distance of the

outer circumference of the tire. For illustrative purposes, assume

a 15 inch tire has an average rolling circumference of 7.16 feet.

The distance between targets is representative of one eighth of

the circumference, which in this example is 0.895 feet. This sen-

sor can also be mounted to make use of the drive shaft of a vehi-

cle and positioned to read the knuckles of the u-joint or a tar-

get(s) attached to the u-joint or the drive shaft.

The transmission sensor transmits six pulses for each revolution

of the internal disk. Since most automobile speedometers are

based on 1000 revolutions per mile, approximately 6000 pulses

per mile are obtained. Dividing the pulses received (6000) into

the course length (5,280 feet) shows that each pulse represents

0.880 feet (5,280 divided by 6,000 = 0.880).

The electronic interface amplifier takes pulses already generat-

ed by the vehicle’s existing speed sensor and conditions this sig-

nal. Most vehicle sensors generate more pulses than the DMI

needs so the electronic interface includes a divider circuit. This

circuit changes the 100,000 pulse/mile vehicle sensor pulse out-

put to the 6,000 per mile required by the DMI.

2

AUTOMATIC ERROR CORRECTION (AEC)

AEC is a software generated program that uses velocity and time

calculations to help compensate for errors from the sensor equip-

ment. This is accomplished by constantly comparing the duration

of one sensor pulse to a subsequent pulse. When a pulse is

missed, AEC will flash and the DMI will correct the count. The

AEC will flash constantly on the left-hand side of the distance

screen when sporadic pulses are received, indicating that a prob-

lem exists and must be corrected.

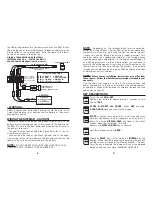

INSTALLATION

NOTE:

You may want to locate a garage or speedometer shop in your

area to perform the installation of the sensor and DMI instrument.

MOUNTING THE NITESTAR

The NITESTAR is designed to be mounted using the supplied

bracket or self-adhesive Velcro

®

strip fasteners that are provided

for direct mount. Determine the location where you will mount the

DMI in the vehicle. This will assist in determining how to route

the power cable for the unit. The DMI should be angled so the

operator is able to see the display and keyboard. Remove the self-

adhesive protective covering from one of the Velcro fastener

strips. Place the sticky side down at the location where you are

locating the DMI. Remove the self-adhesive protective covering

from the matching strip and press firmly to the back of the DMI.

Mount the DMI to the first strip. If using the bracket, repeat the

above procedures and fasten the DMI to the bracket before fol-

lowing the remaining steps.

– WARNING –

Do not mount a Nitestar in any area that may block the driver's

view or cause other obstructions.

MOUNTING THE TERMINAL BLOCK - CAUTION!

All wiring and materials should be installed and routed as far

away as possible from spark plug wires, ignition coil wire, mani-

fold and exhaust pipes. (Use the cable ties supplied with your

Installation Kit to secure wires away from these areas.)

Using the #6-32 screws from the installation kit, mount the ter-

minal block and electronic interface (if used) under the instru-

ment panel near the drivers seat. The fender well inside the

engine compartment on the driver’s side is an optional mounting

location. If using the proximity sensor or mechanical transmis-

sion sensor, follow the directions provided with the sensor. Insert

3