14

E

.0

4.

20

00

•

G

. 1

6.

11

.1

0

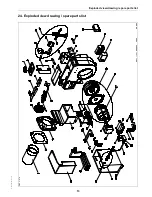

Exploded view drawing / spare parts list

Position

Designation

Pack qty.

Art. No.

1

Burner pipe

1

47-90-27900

2

Diaphragm plate compl. with holder

1

47-90-27885

3

Nozzle assembly compl.

1

37-90-11304

4

Delavan HV1.5 nozzle

1

59-10-50448

5

Ignition electrodes (left + right)

1

47-90-26037

6

Ignition cable G55

1

47-90-27621

7

Air control handwheel

1

47-90-12100

8

Air damper flange

1

47-90-12099

9

Air damper compl.

1

47-90-12096

10

Housing cover

5

47-90-12095

11

Sight glass

5

47-50-12105

12

Sight glass cover

5

47-50-12106

13

7-pin socket with cable

1

47-90-11839

14

Control unit bottom part S98 9-pin. compl.

1

31-90-22664

15

Satronic TF 834.3 control unit

1

37-90-11285

16

Fan wheel 146 x 52

1

47-90-12104

17

Motor 180 W

1

47-90-12113

18

Motor with fan impeller compl.

1

47-90-27249

19

Coupling

10

37-50-10110

20

Suntec D45B pump with connections

1

47-90-26160

21

Conical nipple AL 13 x 18 x 2

50

38-50-11293

22

Hose nipple R 1/4“ x 8LL

10

37-50-11348

23

Metal hose, nom. size 6

1

47-90-11347

24

Pump - solenoid valve connecting tube

1

37-90-10780

25

Banjo screw R1/8“

10

37-50-10736

26

Conical nipple AL 14 x 10 x 2

50

37-50-10788

27

Solenoid valve R1/4“ SV04

1

36-90-11583

27

Solenoid valve coil

1

47-90-24686

28

Thread reducing adaptor 1/4“ - 1/8“

1

47-90-11303

29

Solenoid valve - oil tank connecting tube

1

47-90-26171

30

Oil tank connection compl.

1

47-90-27627

31

Seal 24 x 16 x 2

10

47-50-10516

32

Drain valve

1

47-90-10472

33

Intake tube compl.

1

47-90-24514

34

Heating coil 1100 W

1

47-90-24505

35

Oil tank G100 compl.

1

47-90-26177

36

Oil tank cover

1

47-90-24520

37a

Oil tank - nozzle assembly connecting tube part 1

1

37-90-10370

37b

Oil tank - nozzle assembly connecting tube part 2

1

37-90-10371

38

Control housing shroud, compl. preassembled

1

47-90-27351

39

Safety thermostat

1

47-90-27327

40

Flush-type thermostat

1

47-90-22805-01

41

Twin microswitch

1

47-90-10601

42

Float

1

47-90-22420

43

Control housing cover

1

47-90-24525

44

Electronic ignition unit Mod. 26/48

1

47-90-26930

45

Flame detector MZ770 compl. with cable

1

47-90-22816

46

Swivel flange compl.

1

47-90-26181

47

Mounting flange seal

5

47-50-24429

48

Air distributor connecting tube

1

47-30-27631

49

Air distributor, compl. preassembled

1

47-90-24568

50

Safety valve

1

47-90-26640

51

Pressure gauge 0-2.5 bar

1

47-90-12121

52

Solenoid valve coil

1

59-90-50368

53

Double reduction nipple 1/4“ - 1/8“

1

44-90-23075

54

Replacement pressure regulator

1

47-90-24594

Summary of Contents for G100 Universal

Page 1: ...G100 Universal Oil Burner Installation Maintenance Manual...

Page 15: ......