6

E

.

3

0

.0

7

.0

7

•

G

.

0

7

.0

6

.1

1

If any of these safety checks do not function as described i.e. they should always result in burner shutdown

and control box lock-out; then it is essential to replace the flame detector with a new KLC flame detector.

For safety and trouble free burner operation, we recommend that the flame detector should be replaced

after every 10,000 hours of burner operation or approximately every 30months for a burner operating on

an average of 10 hours per day.

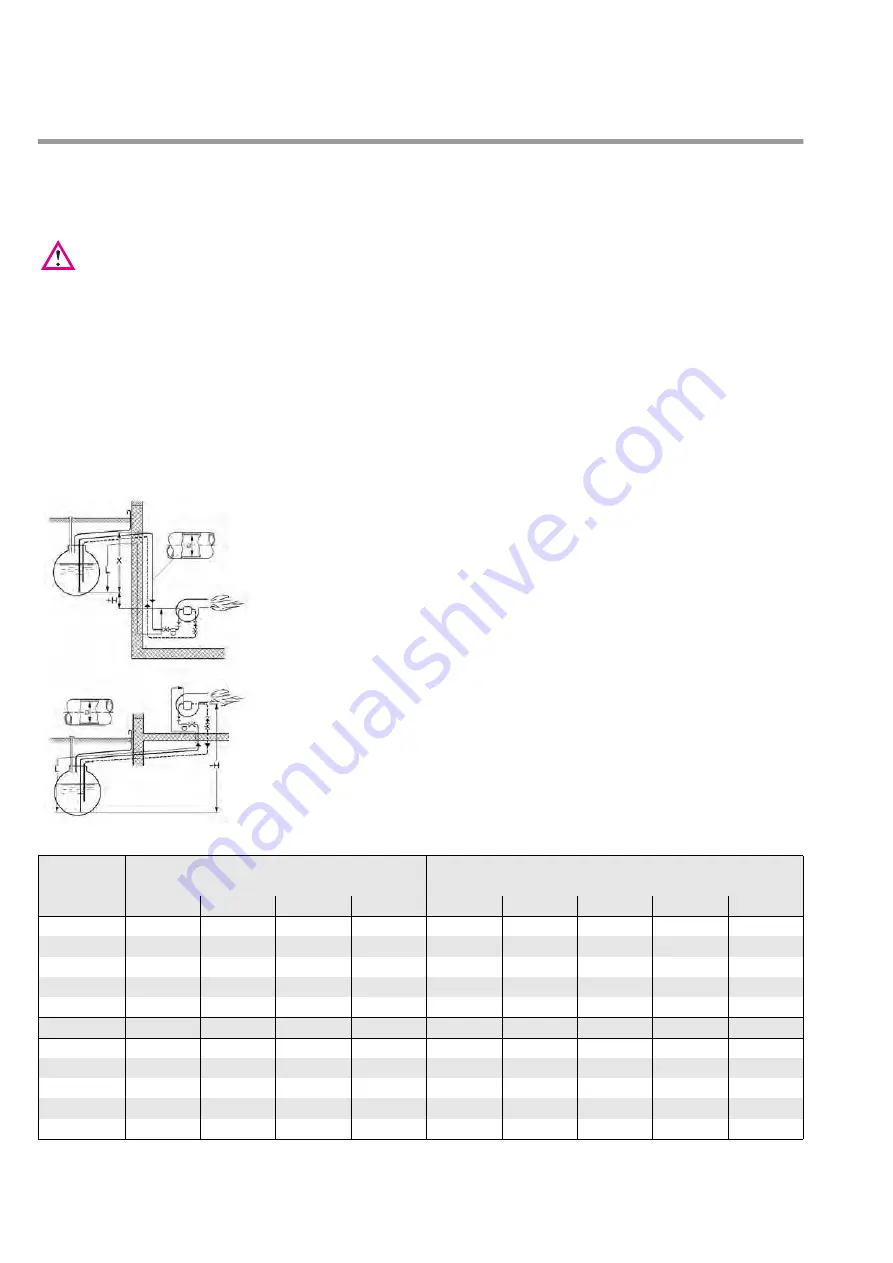

12. Oil connection

Oil lines must be routed to the burner as far as necessary to allow the oil hoses to be connected without

tension. Care must be taken to ensure that the burner can easily be moved into the service position.

Important: an oil filter must be installed before the oil pump.

The tables for single and double line installation show the maximum possible pipe length in dependence

on three factors relating to heating oil type EL 4.8 cST.

• Height differential between pump and tank,

• nozzle delivery rate or pump type,

• pipe diameter.

4 brackets, 1 valve and 1 check valve for resistance were factored into the suction line length. Due to pos-

sible degassing of the oil, dimension "X" should not exceed a length of 4 m.

Double line system

Suntec AJ6

Suntec J7

H (m)

L (m)

L (m)

∅

mm

10

12

14

16

10

12

14

16

20

4.0

13

28

54

93

7

17

34

60

-

3.0

11

25

47

82

6

15

29

52

-

2.0

9

21

40

70

5

12

25

45

-

1.0

8

17

34

59

3

10

21

37

-

0.5

7

16

30

53

3

9

19

34

-

0

6

14

27

48

2

8

16

30

77

-0.5

5

12

24

42

-

6

14

26

67

-1.0

4

10

20

36

-

5

12

22

58

-2.0

2

7

14

25

-

3

8

15

40

-3.0

0

3

7

13

-

-

3

7

22

-4.0

-

-

-

-

-

-

-

-

4