MGN 2800N HP 9

B

URNER

A

IR

C

ONTROLS

The air for combustion is controlled by an adjustable air flap located inside the air inlet on the right

hand side of the burner viewed from the rear. Its purpose is to regulate and control the volume of

combustion air flowing through the burner. Combustion air is controlled by a three position servo

motor. Positions for high and low flame air are adjustable. A fully closed position is incorporated for

when the appliance temperature/pressure is satisfied.

Air Diffuser

The air diffuser is fitted to the front end of the inner assembly and located within the flame tube.

Its function is to control the volume of combustion air and create a pressure drop over the burner

head to ensure good fuel/air mixing and flame stability.

Air Pressure Switch

The air pressure switch is located on the right side of the burner casing viewed from the rear. It is

required to prove adequate air flow throughout the burner operating cycle. Air flow failure at any

stage will result in burner lockout.

B

URNER

G

AS

C

ONTROLS

Gas Nozzle

The gas nozzle is fitted to the front end of the inner assembly and located in the flame tube. The

holes in the gas nozzle are designed to suit the output of the particular burner model and gas type

being used.

High Gas Pressure Switch

A high gas pressure switch is fitted and pre-wired to the gas train to ensure that if the gas pressure at

the burner head increases above the gas pressure at maximum continuous running, then the burner

will shut down to a safe condition, thus indicating a fault on the governing valve (air/gas ratio valve).

The switch is factory set to the maximum position.

Final adjustment of this switch is described in the

Commissioning

section on page 20.

Low Gas Pressure Switch

The low gas pressure switch is located on the inlet side of the gas valve block on the left of

the burner, viewed from the rear. It is required to monitor inlet gas pressure during the

burner operating cycle. Gas pressure failure will result in safe shutdown of the burner. Final

adjustment of this switch is described in the

Commissioning

section on page

20.

Gas Valve Train

The gas valve train system includes an air/gas ratio controller, safety shut-off valve, and gas

regulator in the start rate line. Three impulse pipes are connected to the air/gas ratio

controller. All are factory supplied. One pipe is connected to the burner hinged extension

and supplies combustion air pressure to the ratio controller. A second pipe is connected

downstream of the valve set and supplies gas pressure to the ratio controller. The third pipe

is vented to atmosphere. Valve adjustments are detailed in

Valve Adjustment Diagram

on

page 13.

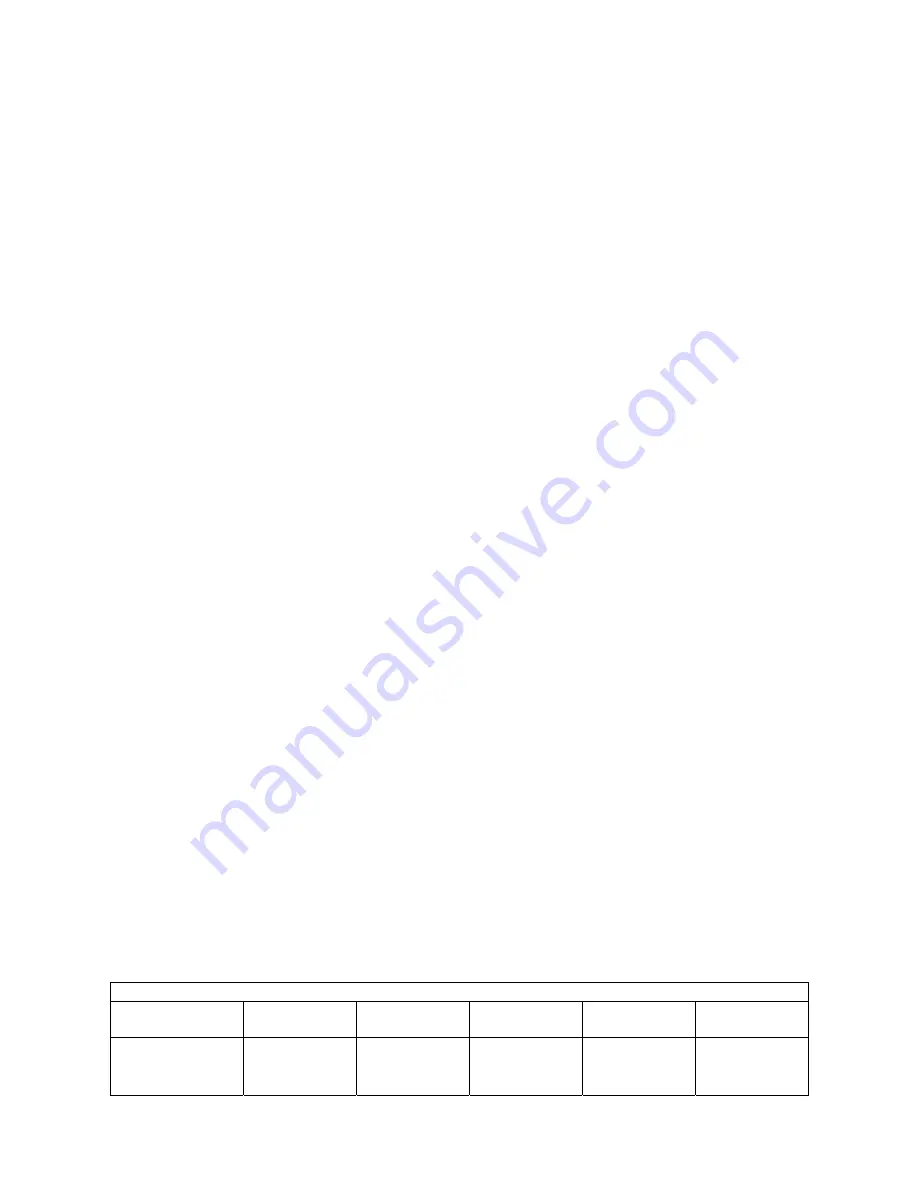

ELECTRICAL

DATA

3 Phase 400V 50Hz

Burner

Model

Motor

(kW / rpm)

Start

Current (A)

Full Load

Current (A)

Main Fuse

(A)

Cable Size

(mm

2

)

MGN 2800N HP

7.5 /2800

57

15.2

40

4.0