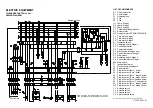

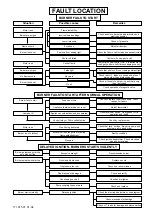

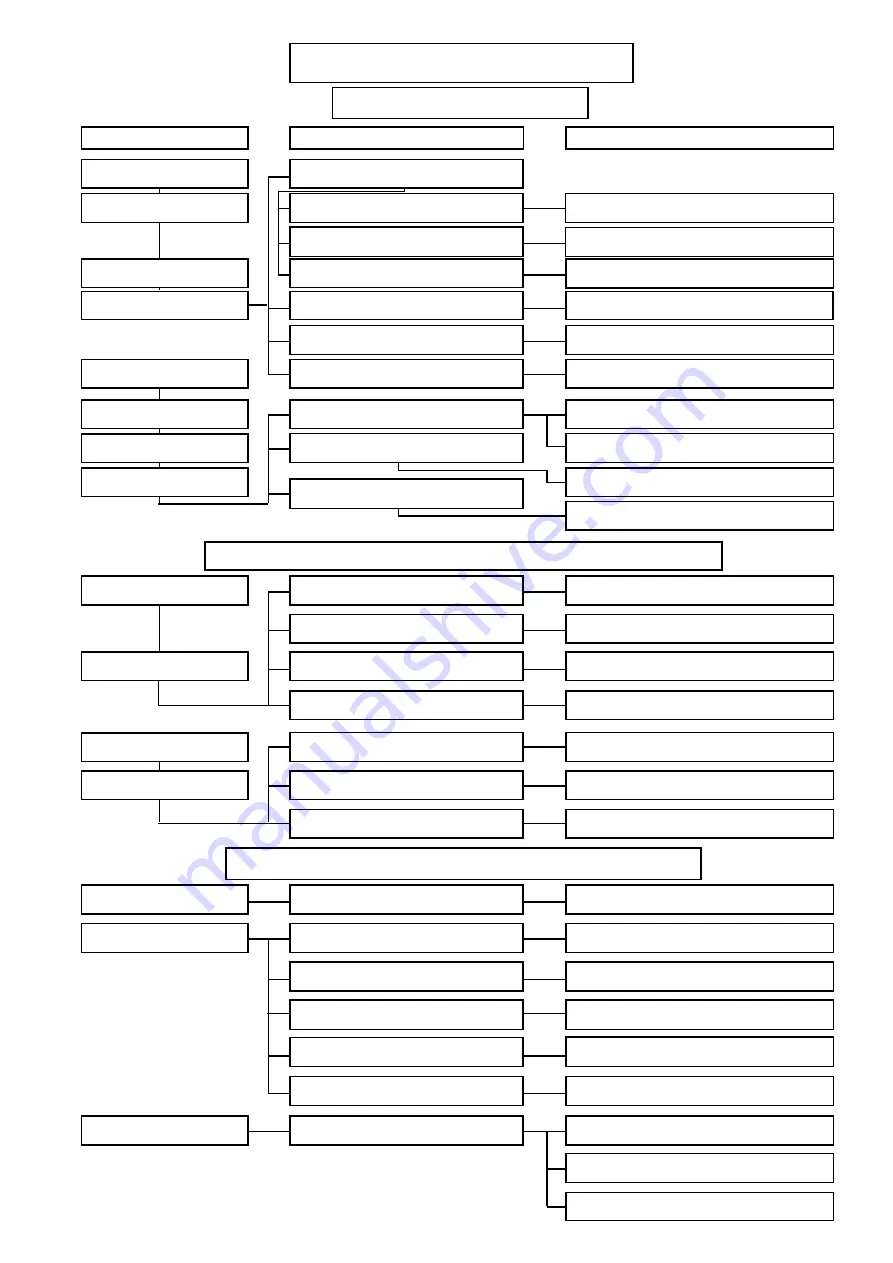

DELAYED IGNITION, BURNERS STARTS VIOLENTLY

BURNER FAILS TO START AFTER NORMAL OPERATION

Remedies

Situation

Possible causes

BURNER FAILS TO START

Check ignition transformer. Check electrode

gap and porecelains

Reset overheat device. Find reason for its

operation and rectify

Check or replace fuse if necessary. Check

reason for failure

Check operation of magnetic valve

Check that photo cell is not seeing ambient light

Motor runs

Flame instabillity

Burner pre-purges

Burner locks out

Motor runs

Photo cell failed

Control faulty

Confirm with new photo cell

Confirm with new control. (NB. it is advisable to

change the photo cell if also changing control)

Burner pre-purges

Burner locks out

No oil

Check that H.T. leads are sound and are not

arcing other than at electrode gap

No flame occurs

Check oil supply to burner - check that pump

is not airlocked

Burner fails to start

Lamp not lit

Fuse has blown

Appliance thermostat has not reset

Appliance overheat device has operated

Control relay or Photo cell defective

Adjust thermostat

Check by replacement

Motor runs

Burner runs to lockout

No oil being delivered

Excessive flue draught is preventing

flame establishment

No spark

Check that tank, oil lines, fire valve, pump and

nozzle are all in good order

Rectify condition

Excessive draught

Recommission burner

Burner pulsates-on start-up

Nozzle partly blocked

Oil pressure too low

Flue blocked or damaged

Fan slipping on shaft

Pump coupling loose or worn

Replace nozzle

Check and recommission

Check and rectify

Check and retighten

Delayed ignition

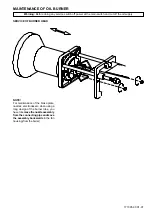

Check the electrode adjustment, see diagram

Check electrodes for damage

Check H.T. leads for damage and disconnection

Check and replace

Incorrect head settings

Low oil pressure

Photo cell not seeing light

Excess air

Burner pulsates on start-up

only with hot flue

Burner starts violently

False light

No spark

Check oil pressure

Check that photo cell is clean and unobstructed

Check nozzle to burner head dimension and

elektrode position

Adjust air damper

Flame occurs

171 915 01 91-06

FAULT LOCATION

Summary of Contents for MOL 1650-3R B70 2-3

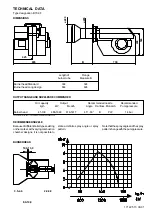

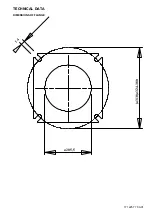

Page 4: ...TECHNICAL DATA DIMENSIONS OF FLANGE 171 225 77 00 01 14 310 324 380 205 5...

Page 14: ......

Page 16: ...NOTES...

Page 17: ...NOTES...