FAULT FINDING

If the Burner Fails to Start

Make sure that all the thermostats and switches in the control circuit are in the ‘made’ position and that

the oil pre-heater ‘excess limit’ thermostat has not tripped. Reset if required. Check that the low oil

temperature thermostat is set correctly for the appropriate fuel.

Check that the electricity supply to the burner is ‘live’ and that the control and main circuit fuses are intact.

If a fuse is found to be ‘blown’ then the cause should be investigated and rectified before proceeding

further.

On steam boilers, check that the ‘water level interlocks’ are in the ‘made’ position.

If the burner is found at lockout (red lockout lamp illuminated)

Reset the burner and observe the starting sequence. (make reference to the

Sequence Diagram and Timing

Charts

for the Flame Failure controls on page 27 for further information

.

Check the fan and oil pump motor overloads and reset if necessary.

Check the operation of the air pressure switch. Failure of the switch to operate prevents the oil pump from

starting.

Flame Occurs Followed by Immediate Lockout

Check the PE cell and the air regulator for correct operation. Check that the oil pressures are correct. If

necessary, check and clean the pre-heater hot oil filter, ensure that there is sufficient oil in the storage tank,

bleed the oil pump in case it is partially air-locked. Check to ensure that all stop/fire valves in the supply

line are fully open. Check residual fuel oil temperature – check the ring main for correct operation in

respect of temperature and pressure.

The Burner Starts With The Correct Oil Pressure But No Flame Appears

Check the ignition system, HT lead connections, electrode gap and the condition of the electrode

insulators. Check that the nozzle cut-off is functioning and that the air damper cable is not broken or

disconnected (the air regulator will be fully open).

It is important to note that continued re-setting of

the burner should be avoided as this can lead to a dangerous situation.

Modulating System

If malfunction of the modulating controller RWF 40 is suspected, check that only compatible components

such as the range insert and pressure/temperature detector have been used. If problems persist then

replacement of the unit should be considered.

Burner Commissioning Sheet

This manual contains a record of the essential information and will have been completed by the

commissioning engineer with individual details of the burner. These details should be verified periodically

and adjusted if variations are noted. Commissioning details must also be record in the

appliance logbook

.

MOL 3400-4100 Issue 2 10/08

Page 23

Summary of Contents for MOL 3400-410

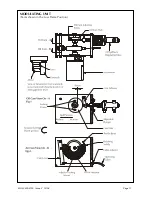

Page 18: ...MOL 3400 4100 Issue 2 10 08 Page 17 MODULATING UNIT Cams shown in the Low Flame Position...

Page 35: ...NOTES...

Page 36: ...NOTES...