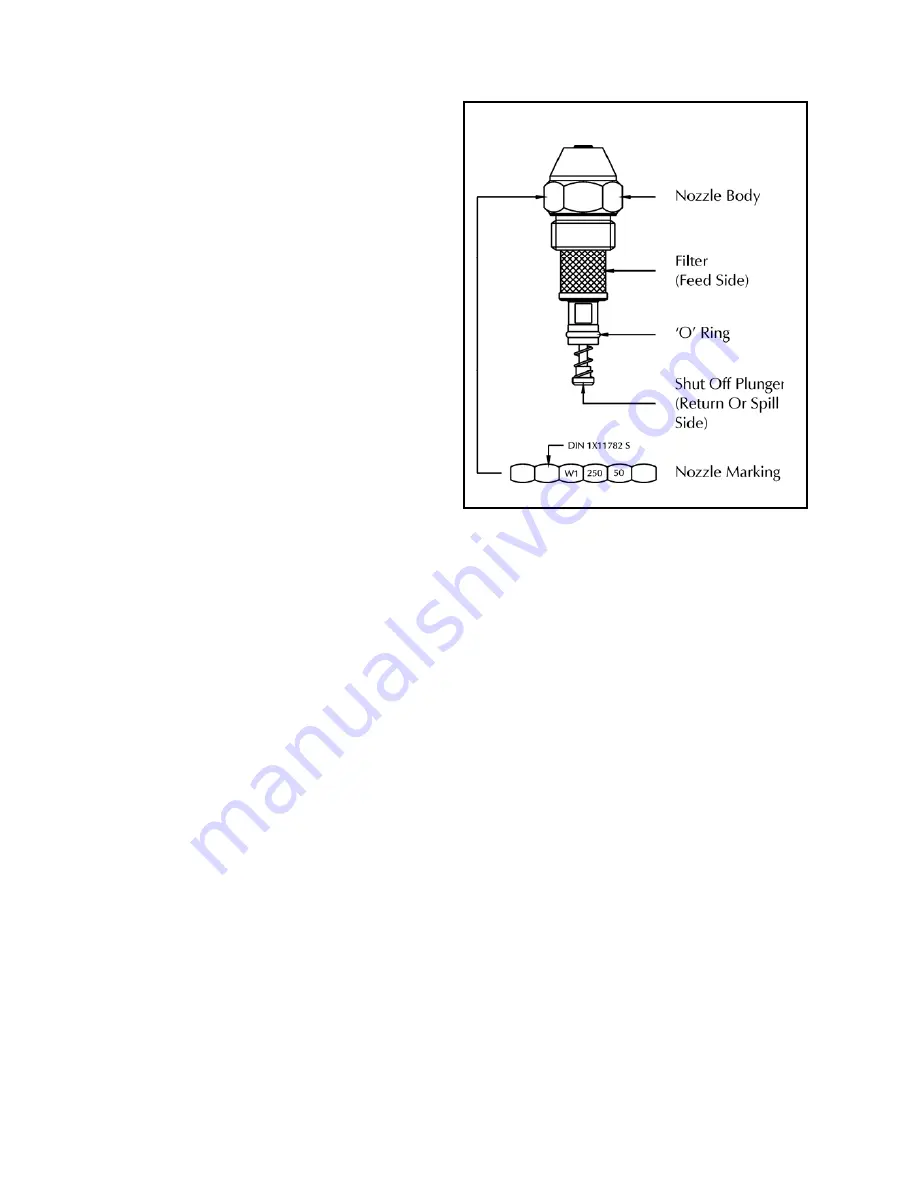

BURNER OIL NOZZLE

The burner lance is designed to operate spill-

back atomisers having a spring-loaded orifice

shut-off needle and a 7/8” x 20 unef fixing

thread.

The Fluidics W1 series atomiser is the preferred

type and this will have been sized at the point of

order to suit the burner rating and application.

When the nozzle has completed 5000 hours of

operation, it should be replaced with the same

make, type and size

as fitted. Failure to do so

will alter the characteristics of the burner and

may impair the performance and efficiency of

the plant.

The nozzle identification code is stamped onto

the face of the hexagonal nut section of the

nozzle body, as shown opposite.

Should any doubts arise concerning the

suitability or performance of the burner nozzle,

please contact the Nu-way Technical department

who will be pleased to assist.

SERVICE & REPLACEMENT

Nu-way Limited Parts & Components Division carry a comprehensive stock, making up the burner systems

described in this handbook. Should it become necessary to order replacement parts, it is important to

quote the burner model, specification and serial numbers to ensure correct expedition of your order.

Nu-way Limited is able to offer ‘on site’ Commissioning, Service and Repair through its worldwide network

of authorised distributors and sales offices.

Please contact the Nu-way ‘Service Department for further information.

MOL 3400-4100 Issue 2 10/08

Page 31

Summary of Contents for MOL 3400-410

Page 18: ...MOL 3400 4100 Issue 2 10 08 Page 17 MODULATING UNIT Cams shown in the Low Flame Position...

Page 35: ...NOTES...

Page 36: ...NOTES...