Combustion Chamber Conditions

The combustion chamber conditions should not exceed those shown on page 32 of this manual.

Burners working with zero rated combustion chamber conditions can be subjected to a maximum negative

condition of 0.05 kPa (0.5 mbar)

Oil System

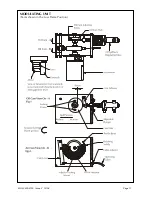

Refer to the drawings on page 10 & 19 for details of the burner oil system.

Oil Supply to the Burner

The oil supply from the storage tank to the burner may be provided by:

a.

Single pipe gravity feed system

b.

Pumped ring main system

Single Pipe System

The height of the main storage tank above the burner and the sizing of the pipe to the burner must be

designed so that the oil pressure at the burner oil pump inlet is not less than 35 kPa (0.34 bar). The

maximum oil pressure at the burner pump inlet must not exceed 500 kPa (5.0 bar) under any operating

conditions.

The pipe must be sized to the full swept volume of the burner oil pump and not the capacity of the burner

nozzles.

Pumped Ring Main System

The pumped ring main is the preferred system of oil supply and is essential for multiple burner installations.

The ring main pumps and supply pipework must be designed to cater for 1.25 times the total swept

volume of the burner oil pumps connected to the supply system.

All oil supply pipes must be constructed and installed to comply with local conditions and appropriate

codes of practice and standards. All pipework must be firmly supported and a Pressure Reducing Valve

(PRV) should be fitted to control the supply pressure.

Burner Pump Capacities

The oil pumps used on Nu-way modulating oil burners are listed in the table on page 26. It is essential

that the full swept volume of the pump be considered when oil supply lines or ring main systems are

calculated.

Filtration

When using fuel oils filtration of the oil is essential. The filtration system should be chosen according to the

individual features of the installation. The ring main system diagram on page 10 gives guidelines. When

the ring main pressure is checked then this should be measured at the burner pump vacuum gauge port to

allow for any pressure drop across the filters.

Failure to provide a good clean oil supply will almost certainly lead to premature wear and rapid failure of

the oil pump unit.

Electrical Power Supply

A three phase 50Hz supply is required (60 Hz Burners are available on request). Power requirements are

tabulated in the

Appendix

of this handbook. The power supply provided must comply with all relevant

Codes and Standards.

MOL 3400-4100 Issue 2 10/08

Page 8

Summary of Contents for MOL 3400-410

Page 18: ...MOL 3400 4100 Issue 2 10 08 Page 17 MODULATING UNIT Cams shown in the Low Flame Position...

Page 35: ...NOTES...

Page 36: ...NOTES...