18

E

.0

4.

99

• G.

13.

11.

02

Service instructions/dimensions

Troubleshooting

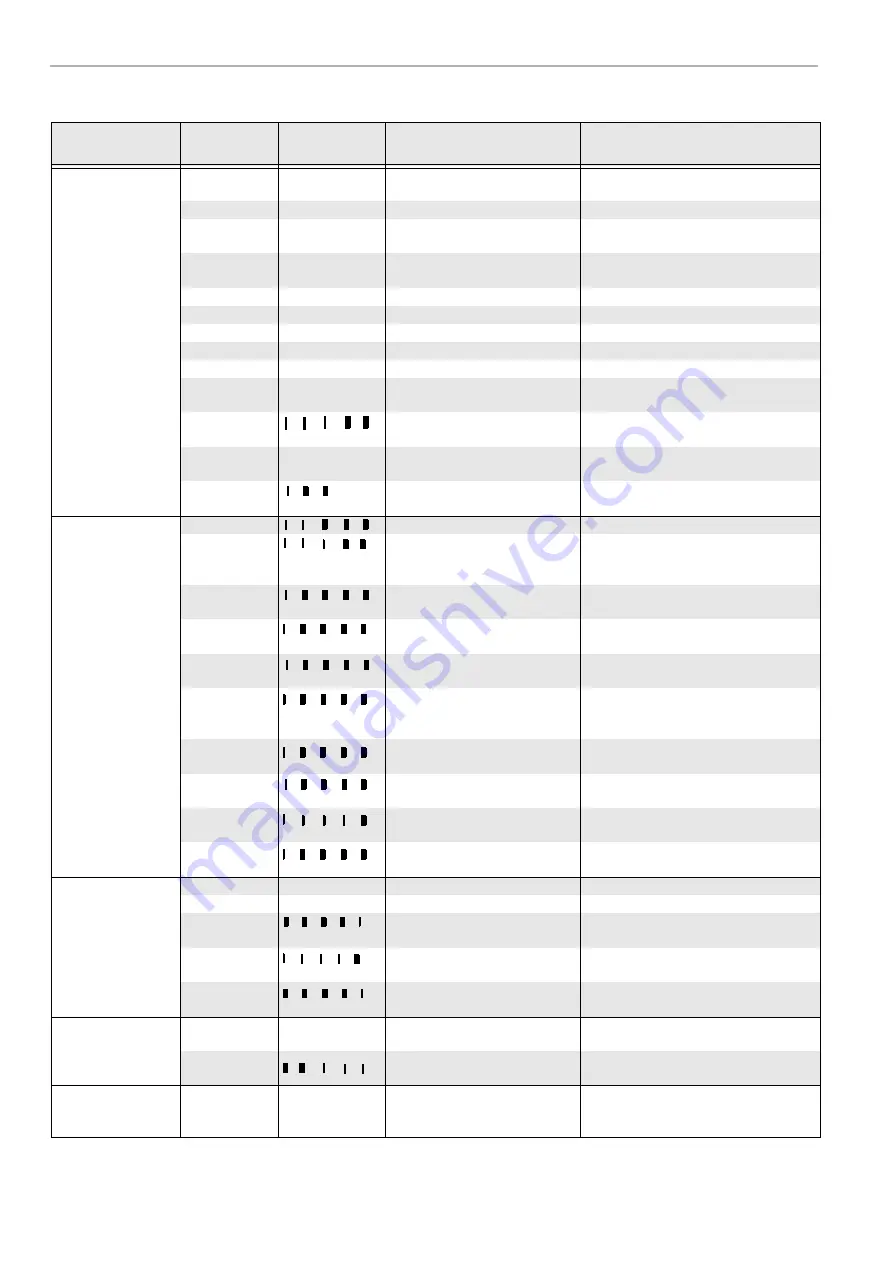

Defect

determined:

Display

MMI 810

Blink code

DMG 970

Cause:

Remedy:

Burner motor does

not start up

as desired

-

Electric supply lead faulty

Rectify faults in electrical

installation

as desired

-

Fuse faulty

Replace

as desired

-

Safety thermostat

locked

Unlock

as desired

-

Temperature of controller set-

ting is exceeded

Renewed start attempt after tempera-

ture drop

as desired

-

Control box faulty

Replace

as desired

-

Leak

Rectify leak

as desired

-

No gas

Safeguard gas supply

as desired

-

Gas pressure monitor faulty

Replace compact unit

as desired

-

Filter in compact unit dirty

Clean or replace

rotates conti-

nuously

-

Air pressure monitor not in idle

position

Check air pressure switch (s. page 16)

blue-black/red

line

Burner motor faulty

Replace

blue-black/red

line

-

No load at terminal 5

Check plug connection and current path

of solenoid valve

-

Mains voltage

<

187 V

Rectify faults in electrical

installation

Burner starts up and

switches to fault

mode before or after

expiry of safety

period

blue

Ionisation message

Solenoid valve leaky, replace KE

blue-black/red

line

Air pressure monitor does not

switch through during pre-venti-

lation

See Page 16

yellow

Ignition influencing of ionization

monitor

See Page 16

yellow

Gas solenoid valve does not

open

Replace compact unit

yellow

Starting gas quantity set

too low

Increase starting gas quantity

yellow

No ignition

Check ignition electrode and

setting, ignition transformer

and cable (see Page 5)

yellow

Phase and zero mixed up

Connect connector unit

in correct phase sequence

yellow, red,

green

Ionisation monitor faulty

Check according to Page 16

yellow, red,

green

Air pressure switch opens

during operation

See Page 16

yellow, red,

green

Gas nozzle dirty or faulty

Replace gas nozzle

Flame extinguishes

during operation

yellow, red

-

No gas

Safeguard gas supply

green

-

Filter in compact unit soiled

Clean or replace

red or green

Flame blow-off

Incorrect burner setting

(see Page 10 ff.)

red or green

Air pressure monitor contact

opens

Check/replace air pressure monitor

(see Page 16)

red or green

Flame signal too weak

Measure flame signal, check ionisation

electrode(see Page 16)

Burner motor starts

up briefly. Control

box goes over to

fault again

-

random error

blink code

Control box has not been fault-

cleared

Unlock control box fault

-

Air pressure switch not in

idle position

Check air pressure switch (s. page 16)

Control box resets

automatically

-

Intermittent fault

(10 sec.)

Intermittent (1-5 sec.)

gas pressure fluctuations trig-

ger gas pressure monitor.

Safeguard gas supply. If necessary,

lower starting point of gas pressure

monitor.