XGN Handbook

Page 10

The XGN series sets new standards in efficient and

reliable operation, having been developed to the

current requirements of the UK and overseas markets.

Delivered ready to install with a pre-wired packaged

control system and plug-in gas train, this can be

arranged for left or right-hand entry.

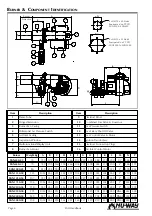

Air Regulation

Air for combustion can be adjusted to give

maximum efficiency. A closed position air control

is incorporated as standard.

Controls & Operation

XGN burners are supplied for two-stage (high-low)

or modulating operation which is automatic, via

the burner controller. Flame supervision is by U V

cell.

Fuel

This handbook covers natural gas only. For other

requirements, refer to Nu-way Ltd.

G

ENERAL

This handbook is structured to enable the user to

proceed from the delivery of the burner to its use.

The conditions to be fulfilled and the controls and

adjustments to be used are dealt with in the

sequence that should be followed. The location

of all the necessary controls and adjustments to

undertake commissioning are illustrated and

supported by appropriate tabular matter and

graphs.

Routine maintenance, fault finding and spare parts

identification complete the handbook.

S

ERVICES

& S

ITE

C

ONDITIONS

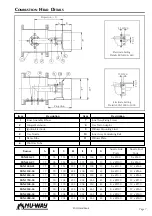

Gas Supply

The gas supply pipework must be constructed and

installed in compliance with the appropriate Codes

and Standards, and comply with all local

conditions. It shall be of sufficient size to satisfy

the pressure and volume flow requirements of the

burner under all firing conditions.

A 90° manual isolation valve must be fitted

upstream of the gas control train to allow the

burner to be isolated for maintenance.

To avoid any restriction in gas flow the size of this

valve should not be less than that of the gas train.

F

EATURES

Flue and Chimney Requirements

The flue and chimney must be constructed and

installed in compliance with appropriate Codes

and Standards, and comply with all local

conditions. It shall be of sufficient size to satisfy

the volume of flue gases at all firing conditions.

Plant Room Ventilation

An adequate dust free supply of fresh air is required

for the burner at both high and low level in

accordance with the appropriate standards.

Existing Appliances

In preparing the appliance to receive the XGN

burner, a careful inspection should be made of its

condition after it has been cleaned thoroughly to

remove all adhering tars, scale and dirt.

Combustion Chamber Conditions

The combustion chamber draught must not exceed

0.25 mbar. If this figure is exceeded, then steps

should be taken to reduce it to this level.

P

ACKAGING

F

OR

T

RANSIT

To safeguard against transit damage the burner may

be despatched partly assembled in either two or

three units.

A

SSEMBLY

If not already fitted, fit the hinged extension / flame

tube assembly to the burner body using the studs

provided, and ensure the gas inlet flange is at the

bottom.

Open the hinged extension and connect the

ignition cable to the electrode. Close hinged

extension.

Fit the 90° flanged elbow to the gas train mounting

flange, then the gas train to the elbow, using the

gaskets nuts and washers provided.

Ensure that the gaskets are seated correctly when

tightening the assembly.

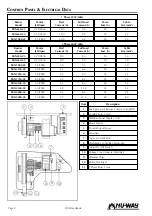

Connect the four number-coded plugs from the

gas valves V1 and V2, the gas pressure switch and

the gas butterfly valve to the MBC sockets 2,3,8 &

14 respectively.

Do not force the plugs into the sockets. If difficulty

is encountered, check the coding to ensure correct

location.

Summary of Contents for XGN Series

Page 4: ...XGN Handbook Page 4...

Page 23: ...Page 23 XGN Handbook XGN450 23 XGN650 23...

Page 24: ...XGN Handbook Page 24 XGN1000 25 XGN1150 38...

Page 30: ...XGN Handbook Page 30 NOTES...

Page 31: ...Page 31 XGN Handbook NOTES...