Page 15

XGN Handbook

•

Press (+) to move the control point to P2,

again making any adjustments to keep the

flame safe and stable.

•

Follow the above procedure through P3, P4

etc. until position P9, the high fire position,

is obtained.

•

With the gas butterfly set at 90°, adjust the

governor on the SKP2x valve to give the

required high flame gas flow.

•

Adjust the air damper position to give the

required combustion analysis.

Note the air

damper position.

•

Switch off the burner and restart the

procedure from entering the pass code.

•

Adjust the value of the air damper at P9 to

that noted above.

•

Scroll through to the GAS EL display and start

the burner.

•

At the ignition point P0, adjust the air and

start gas values to give a good light up.

Ensure that the start rate gas flow

does not exceed 30% of the high

flame gas rate as measured at the

Gas Meter Note the gas and air posi-

tions.

•

Move to point P1 and adjust the gas butterfly

to give the required low flame gas flow. Adjust

the air damper to give the required

combustion analysis.

Note the gas and air

positions.

•

Switch off the burner and restart the

procedure from entering the pass-code.

•

Adjust the value of the gas and air settings to

those noted at points P0, P1 and P9.

•

Scroll through to the GAS EL display and start

the burner.

•

Move to point P2, the firing rate will increase.

•

Adjust the air damper to give the correct

combustion analysis.

•

Repeat the above procedure for points P3

through P8, fine tuning the combustion

analysis as required.

•

When the burner is firing satisfactorily, return

the burner to set point P9.

Two further points

Bu

and

Bo

, which correspond

to the minimum and maximum firing rates can now

be set using the air damper angles that were set at

P1 and P9 respectively.

•

Press keys (1) and (2) together to access the

display point Bu. Wait until the display is

steady. Adjust the value to reflect the air

damper angle at P1.

•

Press keys (1) and (2) again to access the

display point bo. Wait until the display is

steady. Adjust the value to reflect the air

damper angle at P9.

•

Finally, press keys (1) and (2) again to enter

the information into memory.

The procedure is now complete.

F

INAL

A

DJUSTMENTS

Setting the Air Pressure Switch

Switch off the electrical supply to the burner.

Remove the air pressure switch cover. Fit a

manometer to the pressure switch to check the

accuracy of the dial.

Re-establish the electrical supply.

Enter the pass-code as described on page 13 for a

part commissioning. The default settings will not

be displayed. Switch on and the burner will purge

then fire at point PO. Slowly turn the adjusting

dial clockwise until the flame is extinguished; the

burner may go to lockout. Turn the dial one

division anticlockwise and let the burner restart, if

the burner fails to start, turn the dial another

division anticlockwise. Repeat the above

procedure at one division per cycle until the

burner operates. Adjust the dial a further two

divisions anticlockwise.

Switch off the burner, isolate the electrical supply,

fit the cover and remove the manometer.

Setting the Flame Signal

When the burner is operating normally, carefully

turn back the sensitivity control until LED 1 begins

to flicker. Increase the setting again by one or two

increments until both LED’s are lit. If LED 1 does

not flicker even at position 1: Leave potentiometer

at position 1-2. This adjustment should be carried

out when the flame signal current is weakest (at a

cold-start, shortly after flame establishment or af-

ter stabilisation).

The flame signal can be checked by using a

microammeter.

The minimum signal required is 15 µA

The MBC display is designed to give an indication

of the signal, the screen gives a 0 to 4 readout.

See service display screen 18.

Summary of Contents for XGN Series

Page 4: ...XGN Handbook Page 4...

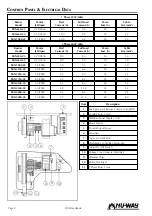

Page 23: ...Page 23 XGN Handbook XGN450 23 XGN650 23...

Page 24: ...XGN Handbook Page 24 XGN1000 25 XGN1150 38...

Page 30: ...XGN Handbook Page 30 NOTES...

Page 31: ...Page 31 XGN Handbook NOTES...