21

G

B

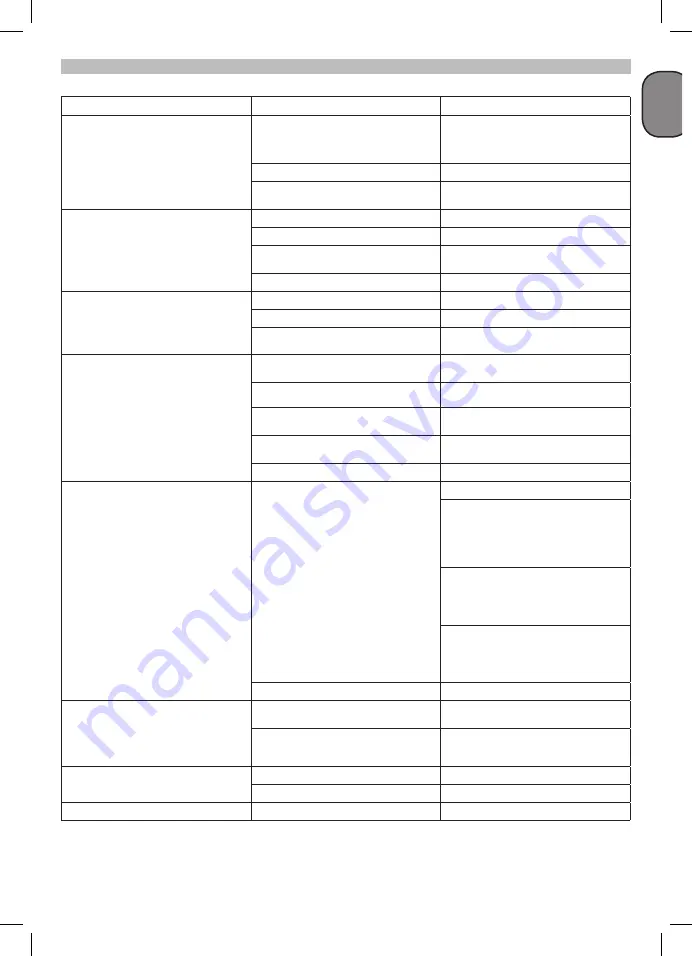

7. POSSIBLE FAULTS AND RELATED PERMITTED REMEDIES

Request the assistance of a qualified electrician for operations on electric components (cables, motor, pressure switch, electric panel, etc).

Fault

Cause

Remedy

Air leak from the valve of the pressure switch.

Check valve does not perform its function

correctly due to wear or dirt on the seal.

Unscrew the hex-shaped head of the check

valve, clean the housing and the special rubber

disk (replace if worn). Re-assembler and tighten

carefully (

figures 15a-15b

).

Condensate drainage cock open.

Close the Condensate drainage cock.

Rilsan hose not inserted correctly in pressure

switch.

Insert the Rilsan hose correctly inside the

pressure switch (

fig. 16

).

Reduction of efficiency, frequent start-up. Low

pressure values.

Excessively high consumption.

Decrease the demand of compressed air.

Leaks from joints and/or pipes.

Change gaskets.

Clogging of the suction filter.

Clean/replace the suction filter

(

figures 11a-11b-11c-11d

).

Slipping of the belt.

Check belt tension (

fig. 14

).

The motor and/or the compressor overheat

irregularly.

Insufficient ventilation.

Improve ambient conditions.

Closing of air ducts.

Check and if necessary clean the air filter.

Insufficient lubrication.

Top up or change oil

(

figures 17a-17b-17c

).

After an attempt to start the compressor, it stops

due to tripping of the thermal cutout caused by

forcing of the motor.

Start-up with head of the compressor charged.

Release the compressor head by using the

pressure switch push button.

Low temperature.

Improve ambient conditions.

Voltage too low.

Check that the mains voltage matches that of

the dataplate. Eliminate any extensions.

Incorrect or insufficient lubrication.

Check level, top up and if necessary change

the oil.

Inefficient electrovalve.

Call the Service Center.

During operation, the compressor stops for no

apparent reason.

Tripping of the thermal cutout of the motor.

Check level oil.

Single-stage, mono-phase versions:

operate on the button of the pressure switch

returning this to the OFF position (

fig. 1a

).

Reset the thermal cutout (

fig. 2

) and restart

(

figures 1b

).

If the fault persists, call the Service Center.

Versions with delta-star starter:

operate on the button of the thermal cutout

located inside the box of the electric panel (

fig.

3c

) and restart (

fig. 6d

).

If the fault persists, call the Service Center.

Other versions:

Operate on the button of the pressure switch

returning this to the OFF position and then to

ON again (

fig. 1a-1b

).

If the fault persists, call the Service Center.

Electric fault.

Call the Service Center.

When operating, the compressor vibrates and

the motor emits an irregular buzzing sound. If it

stops, it does not restart although the sound of

the motor is present.

Single-phase motors:

faulty capacitor.

Have the capacitor replaced.

3-phase motors:

One of the phases of the 3-phase power supply

is missing due probably to blowing of a fuse.

Check the fuses inside the electric panel or the

electric box and if necessary replace those that

have been damaged (

fig. 18

).

Irregular presence of oil in the network.

Too much oil inside the unit.

Check oil level.

Wear on segments.

Call the Service Center.

Leaking of condensate from the vent cock.

Presence of dirt/grit inside the cock.

Clean the cock.

Any other type of operation must be carried out by authorized Service Centers, requesting original parts. Tampering with the machine may impair its

safety and in any case make the warranty null and void.

Та

ше

в

-

Га

лв

ин

г

ОО

Д

www.tashev-galving.com

Summary of Contents for 28FC404NUB012

Page 11: ...11 ON ON 2 3a 3c 1b 3b 4a 4b 1a w w w t a s h e v g a l v i n g c o m...

Page 12: ...12 OFF ON 6a OFF ON 6c OFF ON 6b 5 6d OFF ON 8 7a 7b w w w t a s h e v g a l v i n g c o m...

Page 13: ...13 11b 11a 10 9 11c 11d 12 13a w w w t a s h e v g a l v i n g c o m...

Page 14: ...14 13b 14 15a 15b 16 17a 17b 17c w w w t a s h e v g a l v i n g c o m...

Page 15: ...15 18 19 20 21a 21b w w w t a s h e v g a l v i n g c o m...

Page 94: ...94 w w w t a s h e v g a l v i n g c o m...

Page 95: ...95 w w w t a s h e v g a l v i n g c o m...

Page 96: ...9041949 w w w t a s h e v g a l v i n g c o m...