3

08. 05. 14. Leaflet Number 671588

Installation and Maintenance

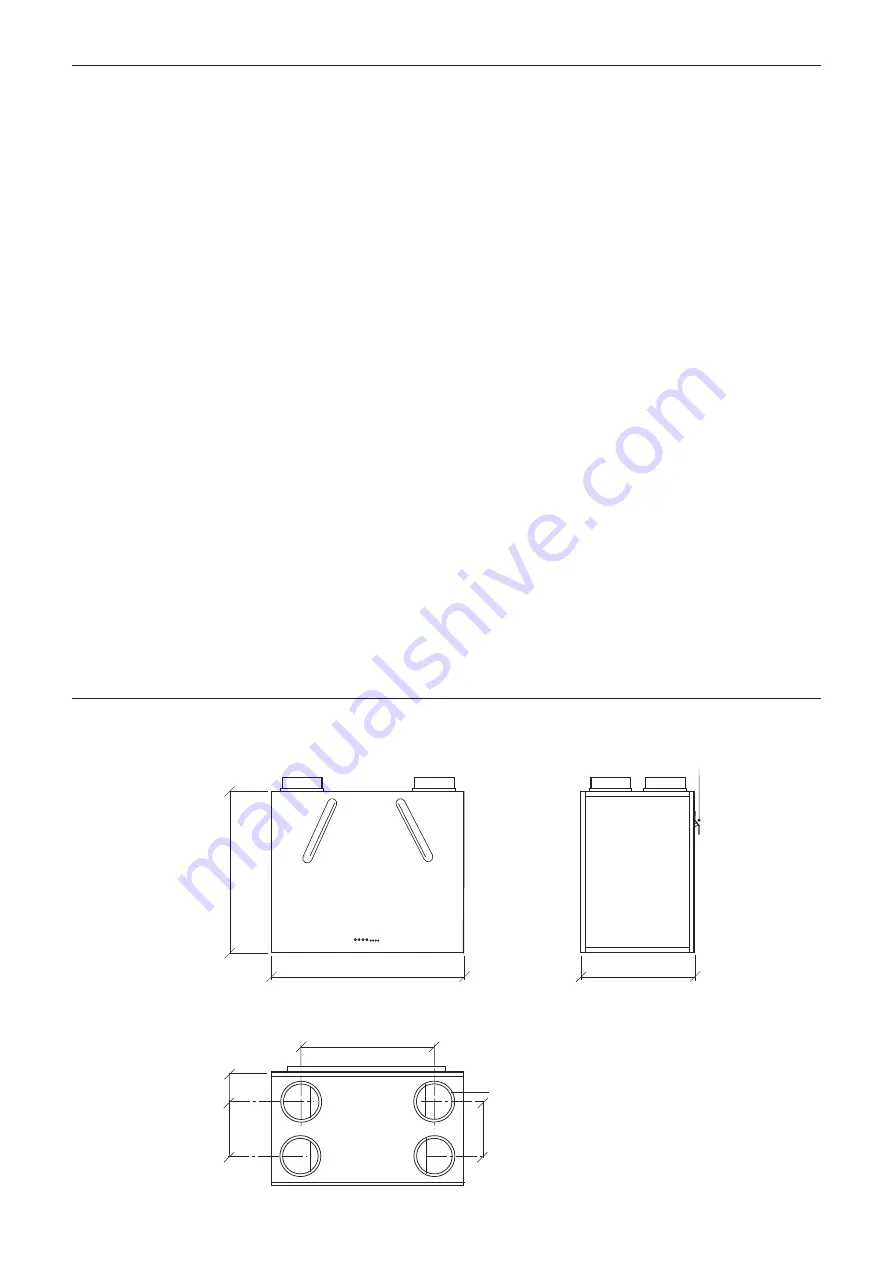

MRXBOX95-WM2 Mechanical Ventilation with Heat Recovery

603

503

Mounting

bracket

353

Side view

Front view

View from top

Spigots

4 x 125mm dia.

419

90

172

172

3.0 Dimensions

Figure 6.

2.5 Air permeability and infiltration

Is the uncontrolled exchange of air between inside and outside

through cracks, porosity and other unintentional openings in

the building. ADF2006 gives an allowance for this in both multi

and single storey buildings, however ADF2010 has an

allowance for multi storey only. Additionally ADF2010 only

applies this allowance for dwellings leaker than 5 m

3

/(h.m

2

) at

50Pa. (See below).

2.6 ADF 2006 Ventilation calculations

Continuous supply and extract

Step 1:

Determine the whole building ventilation rate

from Table

2.

Allow for infiltration by subtracting from this value:

n

for multi-storey dwellings: 0.04 x gross internal volume of

the dwelling heated space (m

3

);

n

for single-storey dwellings: 0.06 x gross internal volume of

the dwelling heated space (m

3

).

Step 2:

Calculate the whole dwelling air extract rate at

maximum operation by summing the individual room rates for

‘minimum high rate’

from Table 1.

(For sanitary accommmodation only, as an alternative, the

purge ventilation provisions given in ADF 2006 can be used

where security is not an issue. In this case ‘minimum high

extract rate’ for the sanitary accommodation should be omitted

from the step 2 calculation).

Step 3:

The required airflow rates are as follows:

n

the maximum extract rate (e.g. boost) should be at least

the greater of step 1 and step 2. Note that the maximum

individual room extract rate should be at least those given

in table 1

. for minimum high rate.

n

the minimum air supply rate should be at least the whole

building ventilation rate found in step 1.

2.7 ADF 2010 Ventilation calculations

Design of MVHR systems

The MVHR system has been sized for the winter period.

Additional ventilation may be required during the warmer

months and it has been assumed that the provisions for purge

ventilation (e.g. openable windows) could be used.

Step 1:

For any design air permeability, determine the whole

dwelling ventilation supply rate

from Table 2.

As an alternative where the design air permeability is intended

to be leakier than (>) 5m

3

/(h.m

2

) 50 Pa, allow for infiltration

for all dwelling types by subtracting from the whole dwelling

ventilation supply rate

from Table 2

; 0.04 x gross internal

volume of the dwelling heated space (m

3

).

Step 2:

Calculate the whole dwelling extract ventilation rate by

summing the individual room rates for ‘minimum high rate’

from

Table 1.

(For sanitary accommmodation only, as an alternative, the

purge ventilation provisions given in ADF 2010 can be used

where security is not an issue. In this case ‘minimum high

extract rate’ for the sanitary accommodation should be omitted

from the step 2 calculation).

Step 3:

The required airflow rates are as follows:

n

the maximum whole dwelling extract ventilation rate (e.g.

boost) should be at least the greater of step 1 and step 2.

Note that the maximum individual room extract rate should

be at least those given

in table 1.

for minimum high rate.

n

the minimum air supply rate should be at least the whole

building ventilation rate found in step 1.

For Scotland refer to BRE Digest 398.