5

04. 11. 19. Leaflet Number 671827

BOXER BPS

ECOSMART CLASSIC CONTROL (ES)

5

Nuaire intend that this manual and any other supportive documents that may

be mentioned should be read and understood by authorised operating and

service personnel before performing any task related to the installation, com-

missioning and maintenance of Nuaire BPS Air handling units and any associated

components.

The operative / service personnel should comply with good industry practice,

the appropriate authority and conformance with all statutory and governing

regulations.

The unit must be manually isolated from the electrical supply and a period of

five minutes allowed to elapse before any access door is opened for the purpose

of general maintenance.

Sharp edges need to be handled with caution; most of the air handling equip-

ment will contain sharp edges on the internal and external surfaces. Care should

be taken to ensure that all personnel are aware of this and precautions are

implemented to ensure that no injuries are caused.

To help operating and service personnel perform tasks safely, please pay atten-

tion to the notes throughout this document (see below for example).

All notes are designed to alert the reader to potential hazards.

IMPORTANT

Information contained in this format is designed to outline important

Notes, Dangers, Cautions and Warnings.

Please ensure that prior to commencing any

activity, the following guide lines are adhered to:

•

During installation, commissioning, operation and

maintenance of an air handling unit, operatives may

be exposed to hazards including, rotating components,

refrigerants and high voltage electricity. If misused or

handled improperly, each of these items has the potential

to cause bodily injury or death.

•

Identification and recognition of inherent hazards is the

obligation of responsible personnel. They must protect

themselves and others by proceeding with care and

consideration to health and safety measures.

•

All risk assessments have been carried out and are in place

prior to carrying out any activity.

•

The relevant protective equipment and attire is worn by

each relevant member of staff.

•

That the unit Nuaire have supplied meets the standards

written in the technical specification.

•

The necessary lifting gear and site plant is available to

lift and position the unit in accordance to the technical

drawings.

•

All electrical equipment is connected and earthed in

accordance with I.E.E. Regulations.

•

The Plant is fully isolated from the mains supply

and allowed to run down for a minimum of five to ten

minutes before opening any access door prior to the

commencement of any maintenance work.

•

When maintenance work is finished, please ensure that

the unit is left in a clean state, and all access doors /panels

are fastened and locked correctly (Locked handle returned

to holder).

•

At no point should a unit be used for the storage of tools

or working equipment.

IMPORTANT

Component parts are usually not fitted with safety guards

i.e. fan inlet. The casing of the unit acts as a

protective guard for all component parts.

2.0 HEALTH & SAFETY

3.0 DELIVERY & RECEIPT OF EQUIPMENT

3.1 OFF LOADING AND HANDLING FROM THE

DELIVERY VEHICLE

All equipment is inspected prior to despatch and leaves the factory in good

condition. Upon receipt of the equipment an inspection should be made and any

damage indicated on the delivery note.

Particulars of damage and/or incomplete delivery should be endorsed by the

driver delivering the goods before offloading by the purchaser.

No responsibility will be accepted for damage sustained during the offloading

from the vehicle or on the site thereafter.

All claims for damage and/or incomplete delivery must be reported to Nuaire

within two days of receipt of the equipment.

The weight of the unit modules and palletised items are displayed on the

packaging.

Some of the modules have an uneven weight distribution, and this will be

indicated by labelling where appropriate.

Offloading and positioning of the equipment is the responsibility of the

purchaser. Items should only be lifted by competent personnel following

appropriate risk assessment.

IMPORTANT

To ensure that the delivery vehicle is loaded according to the

planned method of offloading, Nuaire should be notified, to ensure

coordination.

NOTE: When offloading, care must be taken to ensure that the

AHU is kept level at all times.

IMPORTANT

To ensure that no roof damage occurs additional timber

packaging must be used.

Summary of Contents for BOXER B815H Series

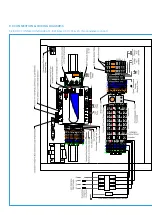

Page 19: ...Figure 18...

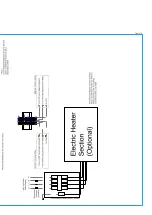

Page 21: ...21 04 11 19 Leaflet Number 671827 BOXER BPS ECOSMART CLASSIC CONTROL ES 21 Figure 19...

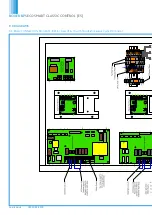

Page 23: ...23 04 11 19 Leaflet Number 671827 BOXER BPS ECOSMART CLASSIC CONTROL ES 23 Figure 20...

Page 25: ...25 04 11 19 Leaflet Number 671827 BOXER BPS ECOSMART CLASSIC CONTROL ES 25 Figure 21...

Page 27: ...27 04 11 19 Leaflet Number 671827 BOXER BPS ECOSMART CLASSIC CONTROL ES 27 Figure 22...

Page 29: ...29 04 11 19 Leaflet Number 671827 BOXER BPS ECOSMART CLASSIC CONTROL ES 29 Figure 23...

Page 31: ...31 04 11 19 Leaflet Number 671827 BOXER BPS ECOSMART CLASSIC CONTROL ES 31 Figure 24...

Page 33: ...33 04 11 19 Leaflet Number 671827 BOXER BPS ECOSMART CLASSIC CONTROL ES 33 Figure 25...

Page 35: ...35 04 11 19 Leaflet Number 671827 BOXER BPS ECOSMART CLASSIC CONTROL ES 35 Figure 26...

Page 37: ...37 04 11 19 Leaflet Number 671827 BOXER BPS ECOSMART CLASSIC CONTROL ES 37 Figure 27...

Page 39: ...39 04 11 19 Leaflet Number 671827 BOXER BPS ECOSMART CLASSIC CONTROL ES 39 Figure 28...

Page 47: ...47 04 11 19 Leaflet Number 671827 BOXER BPS ECOSMART CLASSIC CONTROL ES 47 NOTES...