10

31. 08. 21. Document Number 671746

Nuaire | Western Industrial Estate | Caerphilly | CF83 1NA | nuaire.co.uk

BPS (V/T)-ES

Installation Manual

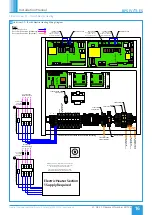

7.0 ELECTRICAL INSTALLATION

The electrical wiring must be carried out by competent persons, in

accordance with good industry practice and should conform to all

governing and statutory bodies i.e. IEE, CIBSE etc.

7.1 Main Unit Power Supply

The control is powered by a 400Vac 50Hz 3 phase & Neutral supply.

This must be isolated local to the unit and fitted with appropriate over-

current and fault protection.

7.2 Electric Heater Power Supply

For models with electric heating, the heating circuit is powered by 1 or

2 separate, higher current, 400Vac 50Hz 3 phase & Neutral supplies.

This must be isolated to the unit and fitted with appropriate over-

current protection. The main supply is still required. Electric heater

elements are protected by a fail-safe over-temperature switch which

will disconnect the heater supply if a temperature of 80°C is reached.

Once the elements cool, the switch will reset but a power cycle is

required to reset the heater supply contactor.

7.3 Power Supply Details - FLC

Unit Size

Unit (FLC)

Unit with Electric Heater

(Electric Heater Models Only)

B*07V/**ES

4.3 A

4.3 A + 17.5 A †

B*07T/**ES

8.3 A

8.3 A + 17.5 A †

B*12V/**ES

6.8 A

6.8 A + 35 A †

B*12T/**ES

10.8 A

10.8 A + 35 A †

B*17V/**ES

9.5 A

9.5 A + 52.5 A †

B*17T/**ES

13.5 A

13.5 A + 52.5 A †

B*22V/**ES

10 A

10 A + 52.5 A †

B*22T/**ES

14 A

14 A + 52.5 A †

B*32V/**ES

15 A

15 A + 35 A + 52.5 A ‡

B*32T/**ES

15 A

15 A + 35 A + 52.5 A ‡

B*42V/**ES

19 A

19 A + 52.5 A+ 52.5 A ‡

B*42T/**ES

22.5 A

22.5 A + 52.5 A + 52.5 A ‡

* Denotes any Character.

† These heater models require a separate power supply for the electric

heater section, with an appropriate over-current protection device.

‡ These heater models require two separate power supplies for the

two (2) electric heater sections, each with an appropriate over-current

protection device.

7.4 Wiring

All inter-connections between circuit boards, blowers and sensors are

made at the factory. This diagram only shows the essential field wiring

points for clarity.

Remove link wire if switched live signal, an enabler or BMS signal is

connected.

If inlet and outlet dampers are fitted, remove the damper link

wires. This will allow a 1 minute delay before starting the fans.

7.4.1 Switch Live

Switch Live (SL) terminal - A signal of 100-230V a.c. will activate the

switch live signal.

Switch Live 2 (SL2) terminal - A signal of 100-230V a.c. will activate the

switch live 2 (Fan Boost) signal.

A signal from an isolating transformer will produce an

unpredictable result and is not recommended.

Extra low voltage versions of the switched live signals are also available.

Link two contacts to activate the signal.

7.4.2 Volt Free Contacts

The volt free contacts are not fused. If these are used to power any

external equipment, the installer must provide adequate fusing or other

protections. These contacts are rated at 5A resistive, 0.5A inductive.

Run connections

- Contacts closed when fan is running.

Fault connections-

No Fault = contacts are closed.

Fault = contacts are opened.

Heat demand

-

Contacts closed when heating is selected.

Thermal Wheel Fault Contacts 14, 15

Supply Filter dP NC Contacts 12, 13

Extract Filter dP NC Contacts 10, 11

Pump Fault Contacts

25

Volt Free Contact Wiring