Isolation - Before commencing work make sure that

the unit and Nuaire control are electrically isolated

from the mains supply.

5.

0 Wiring

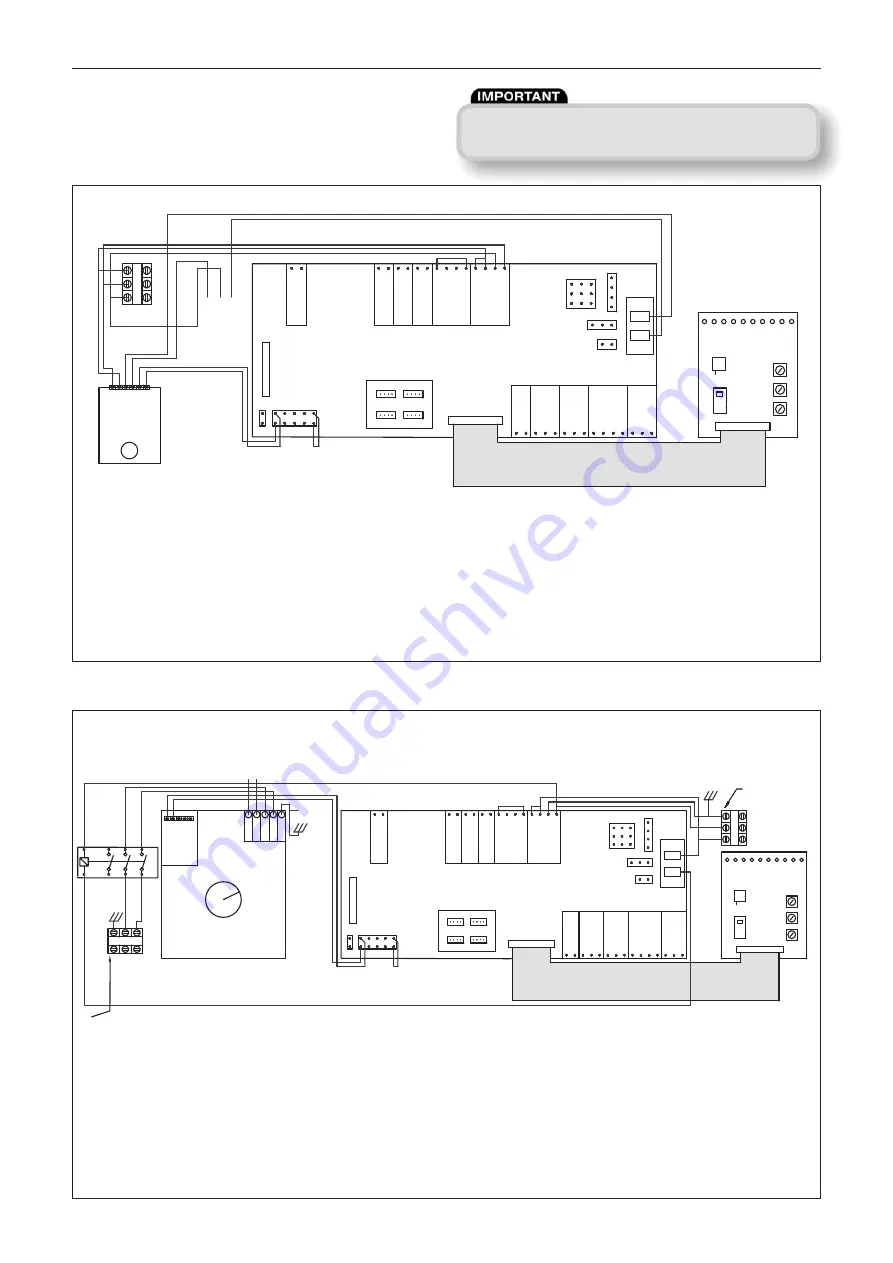

Wiring Connections for units with Ecosmart Control.

Wiring for units with Electric Heater 3Kw

Fig 14:

Wiring for units with Electric Heater 4.5 – 9 Kw

Fig 15:

Installation, Operating and Maintenance Instructions

INV

DRIVE

18V

EN2

EN1

0V

0-10V

BK

WHT

RED

0V

0-10V

18V

0V

0-10V

SET

POINT

CO2

IN

BMS

HEAT

SENS

FAULT

RUN

HEAT

DEMAND

DAMPER

OP

CL

N

RET

SUPPLY

N

E

L

SL

Net Ecosmart

P IN

0V

0-10V

Standby

Fan1

Fan 2

Heating

Cooling

Fault

Frost

Tx

Rx

PWR

Min

Max

SL

Run-On

Trickle

0

1

650462 (830109)

Test

Neutral 230V/220V

Live 230V / 220V

Live Load

Neutral Load

Sensor

Sensor

HEATER NEUTRAL

HEATER EARTH

HEATER LIVE

E

N

L

Heater Temperature Settings

INV

DRIVE

EN2

EN1

0V

0-10V

BK

WHT

RED

0V

0-10V

18V

0V

0-10V

SET

POINT

CO2

IN

BMS

HEAT

SENS

FAULT

RUN

HEAT

DEMAND

DAMPER

OP

CL

N

RET

SUPPLY

N

E

L

SL

Net Ecosmart

P IN

0V

0-10V

18V

Standby

Fan1

Fan 2

Heating

Cooling

Fault

Frost

Tx

Rx

PWR

Min

Max

SL

Run-On

Trickle

0

1 650462

(830109)

Test

A1

A2

4T2

3L2

R2

2T1

1L1

6T3

5L3

Heater

GND

Heater Live

Heater Neutral

Thermistor T Thermistor R

Signal 0V

VE

OIP 5V

Note:

Customer connections

for electric heater.

40amp draw.

E

N L

L

N

E

Heater Temperature Settings

Note:

Customer connections

for fan and control.

5amp draw max.

5

18. 10. 17. Leaflet Number 671679

Notes: Local isolator (by others)

All inter-connections between circuit boards, blowers and sensors are made at the

factory. Remove link wire if switched live signal, an enabler or BMS signal is connected.

COOL DOWN PROTECTION (ELECTRIC HEATER) NOTE: Ecosmart cool down protection

is activated if the fan is disabled whilst the electric heater is enabled. The unit reacts by

running the fan for a cool down period of 10 minutes; this allows any residual heat left by

the operation of the electric heater to dissipate

safely

.

Notes: Local isolator (by others)

All inter-connections between circuit boards, blowers and sensors are made at the

factory. Remove link wire if switched live signal, an enabler or BMS signal is connected.

COOL DOWN PROTECTION (ELECTRIC HEATER) NOTE: Ecosmart cool down protection

is activated if the fan is disabled whilst the electric heater is enabled. The unit reacts by

running the fan for a cool down period of 10 minutes; this allows any residual heat left by

the operation of the electric heater to dissipate

safely

.

DAVE Supply Fans (ES Models) 50/60Hz