Isolation - Before commencing work make sure that

the unit and Nuaire control are electrically isolated

from the mains supply.

5

.0 Wiring

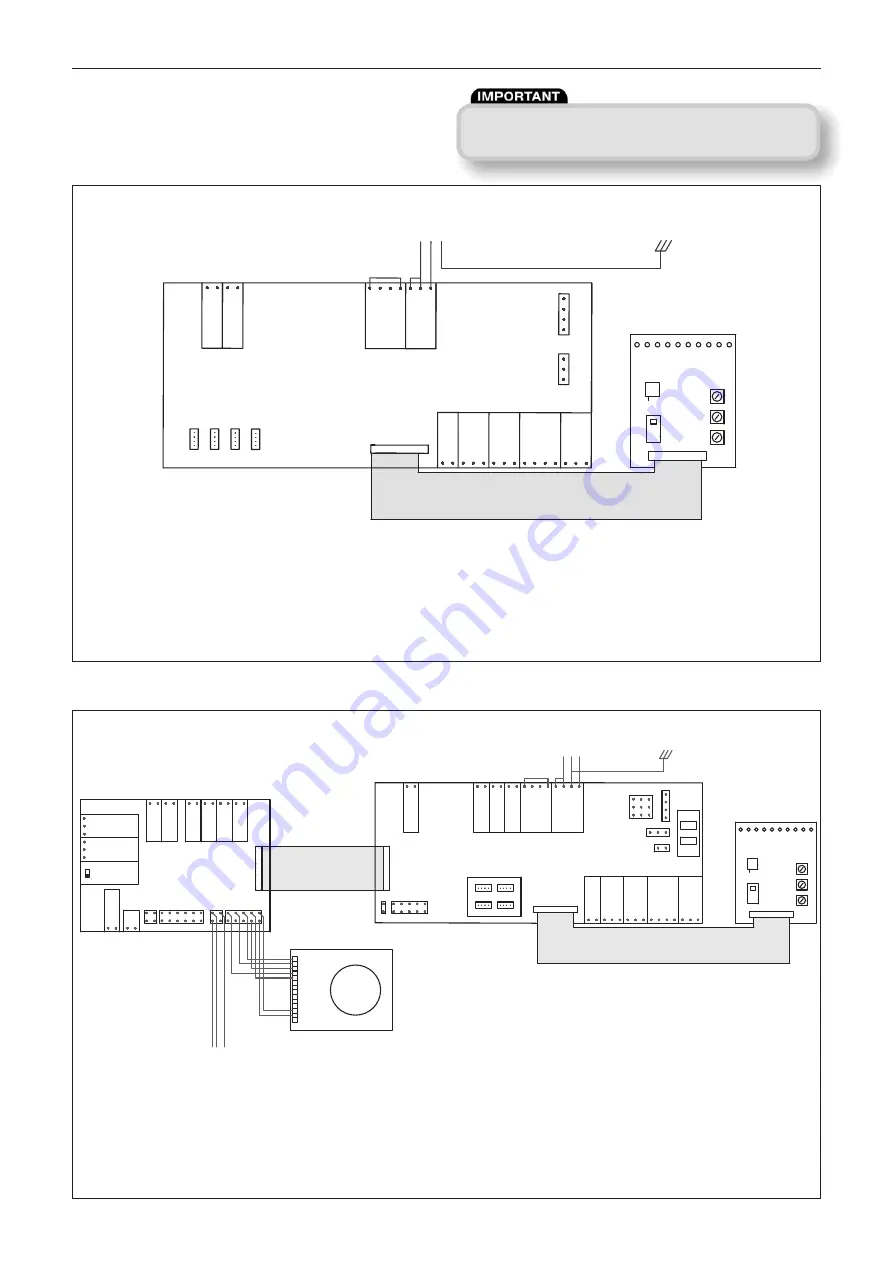

Wiring Connections for units with Ecosmart Control.

Wiring for units with No Heater

Fig 16:

Wiring for units with LPHW

Fig 17:

Installation, Operating and Maintenance Instructions

Standby

Fan1

Fan 2

Heating

Cooling

Fault

Frost

Tx

Rx

PWR

Min

Max

SL

Run-On

Trickle

0

1

650462

(830109)

Test

P IN

E

V I

R

D

V

N

I

0V

0-10V

18V

EN2

EN1

0V

0-10V

BK

WHT

RED

0V

0-10V

18V

0V

0-10V

T

E

S

T

N

I

O

P

N

I 2

O

C

BMS

FAULT

RUN

DAMPER

OP

CL

N

RET

SUPPLY

N

L

SL

Note:

Customer connections

for fan and control.

5amp draw max.

INV DRIVE

EN2

EN1

0V

0-10V

BK

WHT

RED

0V

0-10V

18V

0V

0-10V

SET POINT

CO2 IN

BMS

HEAT SENS

FAULT

RUN

HEAT DEMAND

DAMPER

OP

CL

N

RET

SUPPLY

N

E

L

SL

Net Ecosmart

P IN

0V

0-10V

18V

Standby

Fan1

Fan 2

Heating

Cooling

Fault

Frost

Tx

Rx

PWR

Min

Max

SL

Run-On

Trickle

0

1 650462 (830109)

Test

1

2

3

4

5

6

7

8

9

10

11

12

13

14

24v

24v

O/P 1

O/P 1

O/P 1

T8109C

T8109C

Honeywell

T8078C

DX

COIL

COOL

DEMAND

DX-1

FROST ALARM

DX-2

INLET

SENSOR

OUTLET

SENSOR

HEATING CONTROLCOOLING CONTROL

0V

SETPOINT0-10V

10V

0V

DEADBAND

0-10V

10V

AUTO

HEAT/COOL

OFF

ON

COOL

SENSOR

ACTUATOR CONTROL (WHITE)

ACTUATOR CONTROL (BLACK)

ACTUATOR CONTROL (RED)

Note:

Customer connections

for fan and control.

5amp draw max.

6

18. 10. 17. Leaflet Number 671679

Notes: Local isolator (by others)

All inter-connections between circuit boards, blowers and sensors are made at the factory.

Remove link wire if switched live signal, an enabler or BMS signal is connected.

Notes: Local isolator (by others)

All inter-connections between circuit boards, blowers and sensors are made at the factory.

Remove link wire if switched live signal, an enabler or BMS signal is connected.

FROST PROTECTION (LPHW) NOTE:

Ecosmart frost protection is activated when the outlet

air of the unit is 4

o

C or below, when this temperature is reached, the unit reacts by shutting

down the fan to prevent a ‘wind chill’ effect reducing the temperature to a point whereby

the coil could freeze and burst. The unit will also drive open the LPHW valve to a fully open

position to allow full water flow through the coil and the main PCB will close the ‘Heat

demand’ contacts. These contacts could be used to send a signal to activate the boiler and/

or valve to open to provide heat if not already doing so.

DAVE Supply Fans (ES Models) 50/60Hz