Isolation - Before commencing work make sure that the

unit, switched live and Nuaire control are electrically

isolated from the mains supply and switched live supply.

The filters fitted inside the unit are protected with a

plastic film. Prior to commissioning remove the covers

(fig 15), take off the film and replace.

7

27. 11. 17. Leaflet Number 671721

Installation and Maintenance

The WH1 Wall Mounted Range of Units

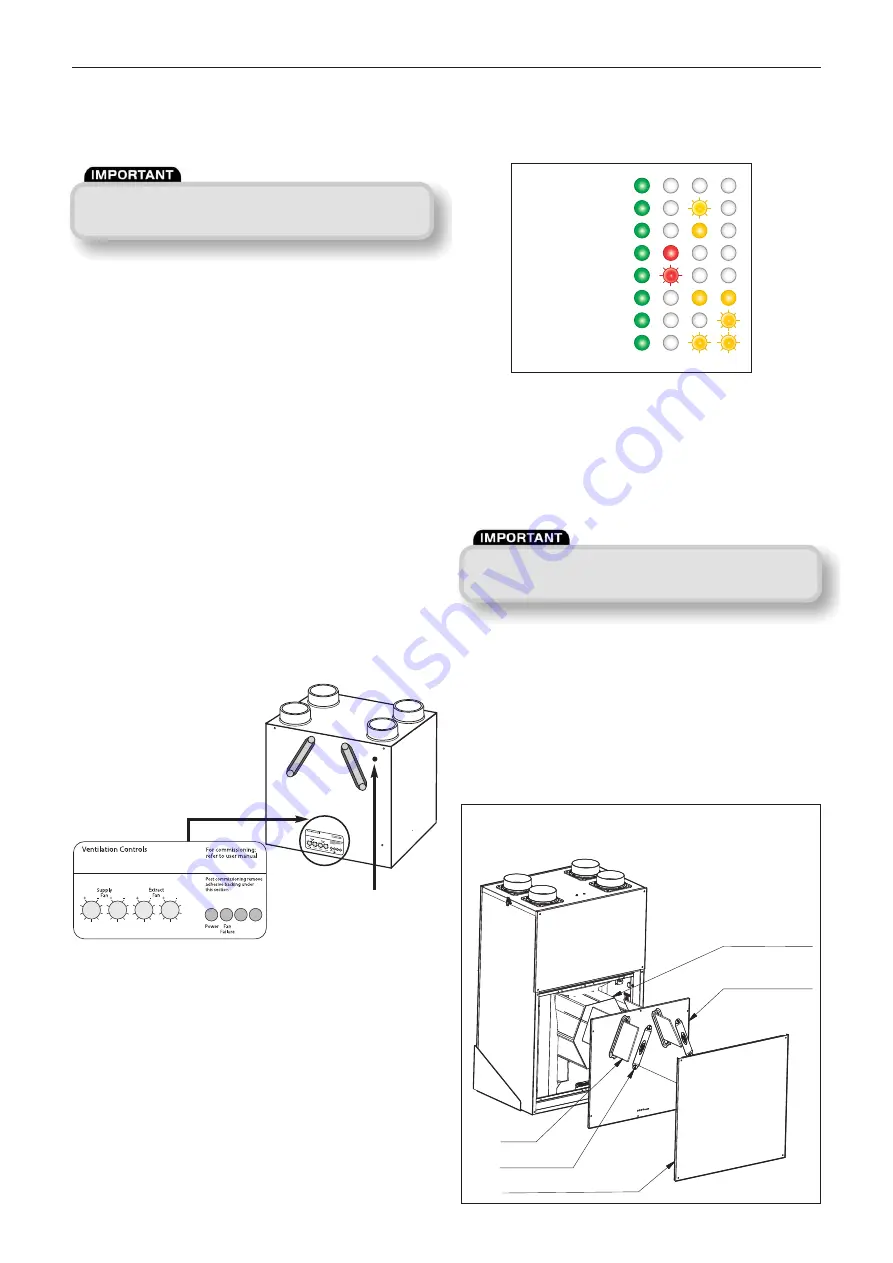

Figure 14. Detail of unit control

on front panel.

(Standard configuration only).

Humidity

adjustment.

(AB unit only).

Filter

Filter cover

Outer enclosure cover

MVHR unit cover

Heat exchanger

Heat exchanger

Figure 15. Removing the two filter covers on the front panel of the

unit. The filters can be removed by pulling on the black tab on the

visible end of the filters.

6.0 Commissioning

All infomation on this page is specific to the MVHR unit fitted

inside the enclosure, the front panel of the enclosure must be

removed to gain access.

2/

For the required air flow rates please refer to the design

specification for the property, follow 2.4, or refer to building

regulations ADF 2010.

3/

The unit is supplied with independent control for both normal and

boost airflows. (see fig. 14).

4/

Correct commissioning is essential to ensure the ventilation air

flowrates are met. It also ensures the unit is not over

ventilating

and causing excessive power consumption.

5/

Commissioning should be carried out in accordance with building

regulations document “Domestic ventilation compliance guide”.

www.planningportal.gov.uk/building regulations/approved

documents/partf/associated.

A calibrated moving vane

anemometer and hood will be required to carry out

commissioning.

6/

Adjustment valves should be locked in place to prevent further

adjustment.

7/

Once commissioned the home owner / tenant should be informed

that the unit should not be adjusted as it will have a detrimental

effect on the indoor air quality and could result in condensation

and mould growth. The label covering the control has an adhesive

panel which should be removed post commissioning to prevent

tampering.

8/

Speed 1 is limited to never exceed the speed 2, when commissioning

the speed 2 should always be set first.

6.1 Speed 3

The unit has to ability to override both speed 1 and speed 2 to operate

the fan to maximum airflow. See wiring diagram for details of operating

this facility.

6.2 Humidity adjustment

(AB unit only).

This product contains an internal humidity sensor fitted into the airflow

extracting from the wet rooms. When the unit senses that the humidity

exceeds the set point the unit will boost to that set by the commis-

sioned boost speed. The set point can be found on the front of the unit

(see Fig. 14) and is at its least sensitive when turned fully clockwise.

Note that the sensor is measuring humidity from all the wet rooms at

the same time and should not be relied on to solely boost the unit.

Additional switch should be used local to the wet rooms (see wiring

diagrams).

7.0 Status Indication

The status of the unit is indicated by a series of LED’s on the front

cover. The varients are listed below.

8.0 Thermal Bypass (Non AB models)

In the event of excessive outside temperatures, and to help prevent

over-heating, the supply fan will automatically reduce to a trickle

speed. Under these circumstances additional ventilation measures may

be required e.g. open windows or trickle vents (if fitted).

9.0 Maintenance/Cleaning

We recommend that the two G3 fiters are inspected after 6 months,

and replaced every 12 to 18 months. The filters can be removed from

the unit by removing the two filter covers on the front panel of the

unit. Take hold of the two circular tabs either end of the filter covers

and pull out.

The filter can now be extracted by pulling the removal loop on the

front edge of the filter. Once the filters have been inspected return

or replace them as necessary. Inspect the heat exchanger every

5 years. Generally check for damage and security of components.

Refit cover.

Speed 1

Speed 2

Speed 3

Supply Fan Fault

Extract Fan Fault

Frost Protection

Filter Change

060923

HX Bypass

(AB units only)

Speed

2

Speed

1

Speed

2

Speed

1