Isolation - Before commencing work make sure

that the unit and Nuaire control are electrically

isolated from the mains supply.

3.1 Equipment Access

Access for maintenance and inspection of the SQURBO XBOX

units is generally from the sides of the unit.

Once assembled and in position, sufficient free space must be

available adjacent to the unit for future inspection, maintenance,

component service, repair and replacement and connection of

services.

It is recommended that at least the unit width (vertically arranged

units XBV); or half the overall unit width (horizontally arranged

units XBH) + 100mm be allowed. (note – for units with a horizontal

layout (types XB/XBH), access is typically required to both sides

of the unit casing). Guidance may be found in Approved Document

F 2010.

3.2 Assembly of Equipment

SQURBO XBOX unit sections will be delivered to site in the number

of sections shown below.

Unit

No. of sections

S2 - S5 XBV

1

S6 and S7 XBV

1

S6 and S7 XBH

3

S8 / S9 / S10 XBV / XBH

3

For units with multiple sections, the sections consist of:

Supply fan (includes heater if included), extract

fan and heat exchanger.

Each Section will be labelled with the direction of air flow.

The direction convention must be observed during assembly. The

units may only be operated in their intended installation plane.

Twin (run & standby) extract fan versions are

supplied in the following arrangements;

Sizes S2T to S6T, vertically stacked XBV range: all the fans are

supplied within one single pre-assembled package as standard; the

standby fan is pre-wired to the Ecosmart control if fitted.

Sizes S8T with Ecosmart control (both horizontal and vertically

stacked): the standby fan is supplied bolted to the main fan and

connected to the control as standard.

Sectional units are supplied with matching internal connection

plates with a single bolt hole provided to each corner through

which the sections are bolted together. Unit access panels must be

removed to perform the assembly operation Plates will either have

clearance holes - or one face with a threaded insert and the other

with a clearance hole.

A sealing gasket should be applied as necessary to the mating

faces of the unit frames before bolting together.

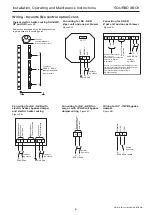

Figure 9: Section assembly plate.

Pipe-work connections to heating and / or cooling coils shall be

made to the appropriate standard, and the entire circuit tested for

tightness. Care must be taken not to over-tighten and distort

connections to coils.

2 Row LPHW Heating Coil Connection size

(standard LPHW unit)

S2 - S5 XBV

= 15 mm plain

S6 / S7 XBH/XBV

= 1.25 in BSP

S8 / S9 / S 10 XBH / XBV

= 2 in BSP

Connection sizes for other coil types are project specific.

Coils are tested during manufacture to 16 Bar (using dry

compressed air). Operation of standard equipment is rated at PN6,

if the intended system requires higher operating pressures; please

contact the Nuaire Technical department for advice.

Electrical connections to the unit shall be made in accordance with

the appropriate product (see below); and installation wiring

diagrams, and shall use appropriately sized and rated cables.

The unit rating label shows the maximum electrical load of the

equipment.

Connections to the unit may include three phase and single phase

supply connections, and a variety of control circuits.

Control circuit connections must be segregated (i.e. routed

separately) from power connections.

Only the prepared apertures in the unit casing may be used for

cable entry. Do not drill or cut the unit casing for this purpose.

The equipment must be earthed and earth-bonded.

Means of local isolation for maintenance purposes are generally

required and are specified and installed by others.

Weatherproof units

Weatherproof units in multiple sections will have sectional roof

components that must be fitted and sealed after the unit sections

are bolted together. (see figure 10). All necessary nuts, bolts,

washers and sealant are supplied with each unit and are normally

bagged and located within the fan section.

The equipment must not be exposed to the weather in an un-

assembled or partially assembled state. All ductwork, sealing and

assembly work must be completed before the unit can be considered

weather-proof.

Figure 10: Weatherproof roof components.

3

08. 06. 18. Leaflet Number 671408

Installation, Operating and Maintenance Instructions

SQURBO XBOX

Use nuts and studs to join

plates of facing sections.

Example of weather kit for horizontal units 6 to 10 XBH, and

weather kit for stacked units 2 to 10 XBV.