8

08. 06. 18. Leaflet Number 671408

Installation, Operating and Maintenance Instructions

SQURBO XBOX

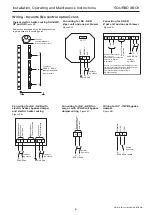

Wiring - for units with Ecosmart control cont.

Unit sizes S7 - S10 Supply fan with LPHW coil

Figure 20:

(A) Is pre-wired to plugs and sockets.

Connections

to Damper

F

A

UL

T R

UN

N

L

SL

DP

CL

N

RET

Remove this link wire if:

1. a switched live signal is connected.

2. A ES-PIR, ES-TC or BMS signal

is connected.

NET connections for

ECOSMART devices

Min Max SL run on

Trickle

Test

0 1

Pwr

Standby

Fan 1

Fan 2

Heating

Cooling

Fault

Frost

Tx

Rx

Ecosmart

Heat demand

signal

Earth

Run signal

Fault signal

HEA

T

D

AMPER

DEMAND

L3

L2

L1

N

E

400V 50Hz

3ph +N mains

1 3 5

2 4 6

(U)

(V) (W)

L1 L2 L3 E

(U)

(V) (W)

L3

L2

L1

12 13 14 15

5 6 7 8 9

10 11

12 13 14 15

C

ONT

A

CT

OR

A1

A2

ON OFF

A

UT

O

HEA

TER/C

OOL

Cooling

demand

signal

Frost

alarm

signal

Signal for

DX1 coil

if fitted

Signal for

DX2 coil

if fitted

25

30

25

Set air off

temperature

of LPHW coil

Connect to inlet

sensor after unit

is assembled

Outlet

sensor

Inlet

sensor

3

2

1

GREEN

BROWN

WHITE

Connect to LPHW

actuator motor

SM24

motor set at

position A

0V

0-10V

BMS signal

A

A