2

nuaire.co.uk

029 2085 8400

13. 03. 19. Document Number 671188

Installation and Maintenance

Ecosmart Boxer Air Handling Units

ESBHS*E

ESBHS*L

ESBHS*LC

ESBHEX*

Plan

Plan

control

packs

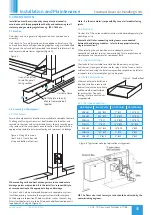

1.1 Typical Unit Arrangements

Unless otherwise stated i.e. RHT in unit code, all control packs are

positioned on the left of the unit when viewed with direction of airflow.

For any alternative control or pipework position, contact us on the

number opposite.

1.1.1 Direct Drive (Sizes 1 and 2)

1.2 Dimensions & Weights

Full details, with project specific documents and drawings are available

from the Nuaire Technical Estimating Department.

1.1.2 Belt Drive (Sizes 3 to 7)

Assembly with base frame

Palletised

Forklift

Slings via spreaders fitted

to unit with base frame

Figure 2.

Figure 3.

Figure 4.

2.0 HANDLING

Upon receipt of the equipment an inspection should be made, and

before commencement of lifting ensure that normal equipment safety

checks have been carried out.

The unit/sections should be removed from the vehicle using a fork lift

or crane. Always handle with care to avoid damage and distortion, and

where lifting slings are employed use spreaders to ensure slings do not

come into contact with the unit case, or control pack (Figure 4).

Correctly position slings to avoid twisting of the unit case and observe

the centre of gravity before the final lift is made.

Note: The weight of the unit from the rating plate.

Dependent on model and size units may be supplied in single or

multi-module sections. Handle each section individually

do not stack

for lifting or storage.