2

029 2085 8400

23. 06. 17. Leaflet Number 670901

Installation and Maintenance

FLAT2000L/R Low Energy Positive Input Ventilation Unit

Points to consider

•

The inlet ducting should be kept as short as possible to avoid condensation

build up on the ducting surface (see fig. 5 and 6).

•

Find the shortest, most direct route from outside of the unit and then to

the discharge grille using the least number of bends (these bends increase

the airflow resistance).

•

Note the location of any joists, pipes, electrical cables etc.

•

Allow adequate access to the front cover to allow filter cleaning.

2.3 Fitting of ducts

To prevent access to live or moving parts ensure ducts are adequately

secured to the spigots by fitting self tapping screws or by other means

requiring a tool. If using duct tape ensure tape cannot be removed

without the use of a tool by securing with tie wraps.

2.2 Fixing the unit to the wall

The unit has three mounting feet. Mark through these feet when

the unit is in the correct position. Drill and plug wall with suitable

fixings. Remove PCB cover and feed the electrical supply cable

through the grommet hole (standard 1mm three core lighting cable is

recommended) in the rear of the unit screw unit to wall (see fig. 3).

Installers must ensure the grommet provided or other suitable

insulated grommet/bushing is used for cable entry.

Supply

cable

position

Supply

cable

optional

position

AIRFLOW

Right Hand Discharge

(when viewed from front)

Figure 3. Supply cable must be secured by passing RH or LH of unit

to clamp cable to the wall (Rear view of unit shown).

2.4 Inlet/Outlet grille installation

If a fly screen is fitted it should be removed from both the internal and

external grille.

NOTE: When installing the internal grille, the louvres

must slant

upwards

to ensure the correct air circulation and the avoidance of

unpleasant down draughts.

The outside wall input grille louvres

must slant downwards

.

Standard 100mm dia ducting or 121 x 60mm ducting is used to connect

the Flatmaster to the input and discharge grilles.

Fixing all necessary ducting

A full range of ductwork and ductwork ancillaries are available. Please

contact Nuaire for further details.

IMPORTANT

Any air intake terminal MUST be installed in accordance with the

appropriate regulation.

As a guide, the BS5440 series of British Standards deals with this issue

and currently states that an air intake must be at a minimum distance

of 300mm from a gas boiler balanced flue. Installers are advised to be

aware of the requirements of this standard when installing ‘through

the wall’ supply air ducting. Similarly, supply and extract air grilles

should be at least 300mm apart.

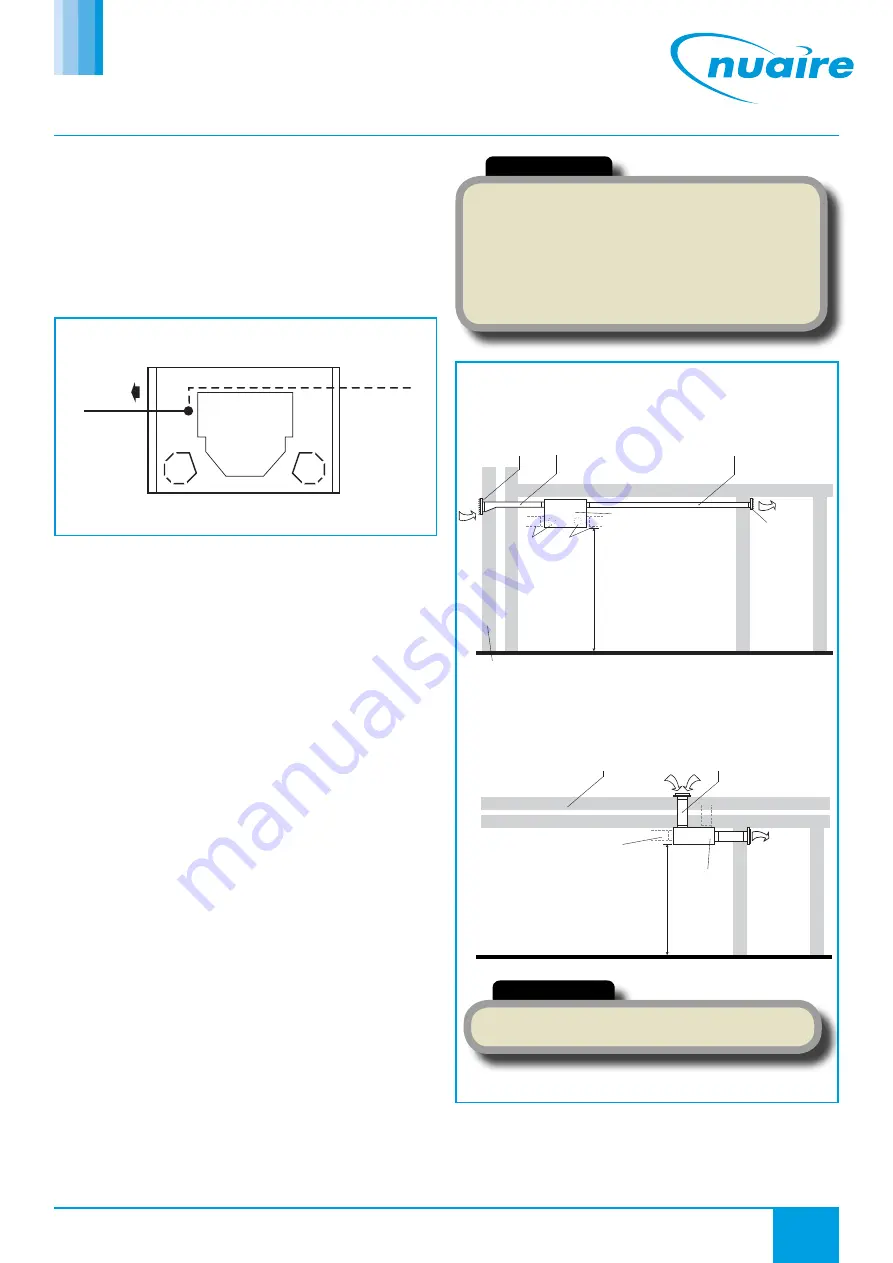

Alternative

spigot positions

(inlet only)

FLATMASTER

FLATMASTER

Note alternative

inlet spigot positions

Input grille

(louvres slant

downwards)

100mm dia / 121x60mm

rectangular ducting

(note input side kept

as short as possible)

100mm dia / 121x60mm rectangular ducting

Outside wall

Room

(typical)

Hallway

(typical)

Discharge

grille (note

louvres

slant

upwards)

Outside wall

Hallway

(typical)

Air input 100mm dia ducting

Air

discharge

Minimum

height 1.8m

Minimum

height 1.8m

Figure 4. Side input installation.

Figure 5. Rear input installation (view from above).

IMPORTANT

The internal grille must not be placed within 1.5m of a smoke

alarm.