2

11. 02. 20. Document Number 671382

Nuaire |

Western Industrial Estate

|

Caerphilly

|

CF83 1NA

|

nuaire.co.uk

MEVDC

Installation Manual

1.2 Important Information

This manual contains important information on the safe and

appropriate assembly, transport, commissioning, operation,

maintenance, disassembly and simple troubleshooting of the product.

While the product has been manufactured according to the accepted

rules of current technology, there is still a danger of personal injury or

damage to equipment if the following general safety instructions and

the warnings contained in these instructions are not complied with.

•

Read these instructions completely and thoroughly before

working with the product.

•

Keep these instructions in a location where they are accessible

to all users at all times.

•

Always include the operating instructions when you pass the

product on to third parties.

1.3 Personal Protective Equipment

The following minimum Personal Protective Equipment (PPE) is

recommended when interacting with Nuaire product:

•

Protective Steel Toed Shoes -

when handling heavy objects.

•

Full Finger Gloves (Marigold PU800 or equivalent) -

when

handling sheet metal components.

•

Semi Fingerless Gloves (Marigold PU3000 3DO or equivalent)

- when conducting light work on the unit requiring tactile

dexterity.

•

Safety Glasses

- when conducting any cleaning/cutting operation

or exchanging filters.

•

Reusable Half Mask Respirators

- when replacing filters which

have been in contact with normal room or environmental air.

Nuaire would always recommend a site specific risk assessment by a

competent person to determine if any additional PPE is required.

2.0 INTRODUCTION

Nuaire's MEV-DC units are designed to provide continuous mechanical

extract ventilation to homes in accordance with Part F of the Building

Regulation 2006 & BRE digest 398.

The case is constructed in grey /blue ABS plastic. The full length access

cover which is located on the underside of the unit, on the opposite

side to the mounting bracket, is retained by four 1⁄4 turn fasteners.

This cover is acoustically lined with flame retardant acoustic foam (full

lining also available).

2.1 Code Description:

MEV DC - ES R G2 L H D4

| | | | | | | |

1 2 3 4 5 6 7 8

1. Range:

Mechanical Extract Ventilation

2. Motor Type:

DC Motors

3. Ecosmart Compatibility:

ES

(optional)

4. Run-On Timer (optional):

R

5. Filtration (optional):

G2 or G4

6. Case Lining (optional):

L

7. Humidistat (optional):

H

8. Damper Kits (optional):

S1, S2, D3 or D4

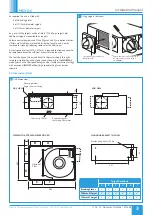

hole.

Fixing screw

Bracket tongues

engage with casing

slots, then unit

rotated up to

align with fixing

screw hole.

2 rubber cable

entry grommets

either side of casing

for external wiring.

1

2

Unit Airflow Path

Unit Mounting Bracket

3.0 INSTALLATION

Installation must be carried out by competent personnel in accordance

with the appropriate authority and conforming to all statutory and

governing regulations.

The fan must be fitted indoors, away from sources of water spray

or steam generation. The fan can be installed at any angle using the

integral mounting bracket supplied (figure 2).

It is assumed that a solid non-reverberant mounting position has been

selected and the electrical mains wiring and any optional control wires

have been made ready.

It is also assumed that compatible ductwork is already installed and

ready to be connected to the 125mm diameter discharge spigot and the

chosen 100mm, 125mm diameter and/or 110 x 54mm rectangular inlet

spigots.

The unit is not fitted with a backdraught shutter (when using the

continuous background vent facility a shutter is not needed). However

a backdraught shutter is available from Nuaire if required.

An integral fixing bracket with a single bolt fixing allows easy mounting

and removal of the unit when necessary. The unit is supplied with the

125mm diameter discharge spigot for fitting during installation.

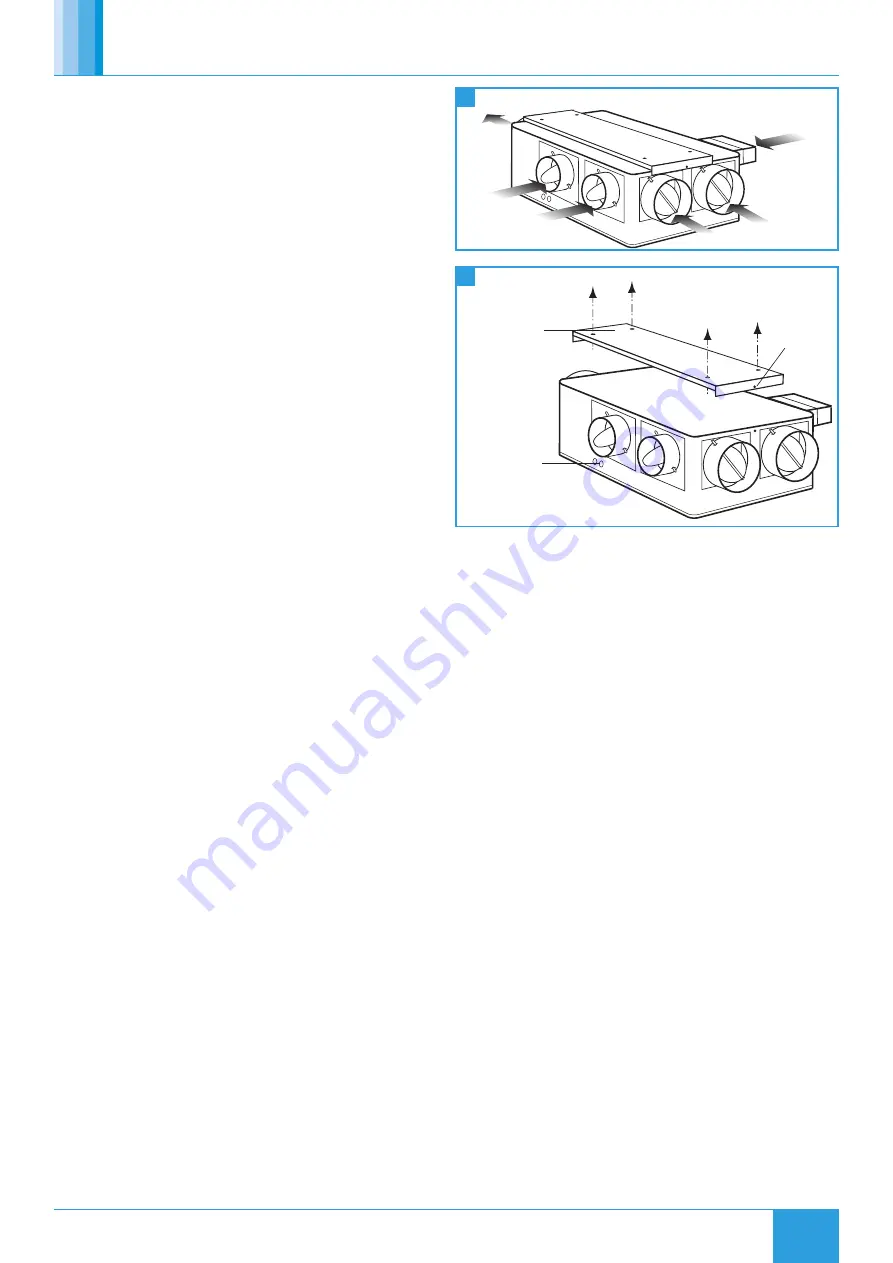

3.1 Unit Installation

The integral mounting bracket supplied can be offered up to position,

the fixing points marked through and the bracket installed with 4

screws by others (figure 2).

Offer the unit into position and locate the bracket into the slots in the

case before fixing with the single bracket fixing screw.

Various damper/inlet spigot positions can be utilised as required to

suit the system ductwork and extract grilles as all spigot positions are

removable.

After the spigots have been located in their correct position, adjust the

damper with a screwdriver (figure 4).