4

07. 09. 21. Document Number 671822

Nuaire | Western Industrial Estate | Caerphilly | CF83 1NA | nuaire.co.uk

MRXBOX(AB)-ECO2-1Z

Installation Manual

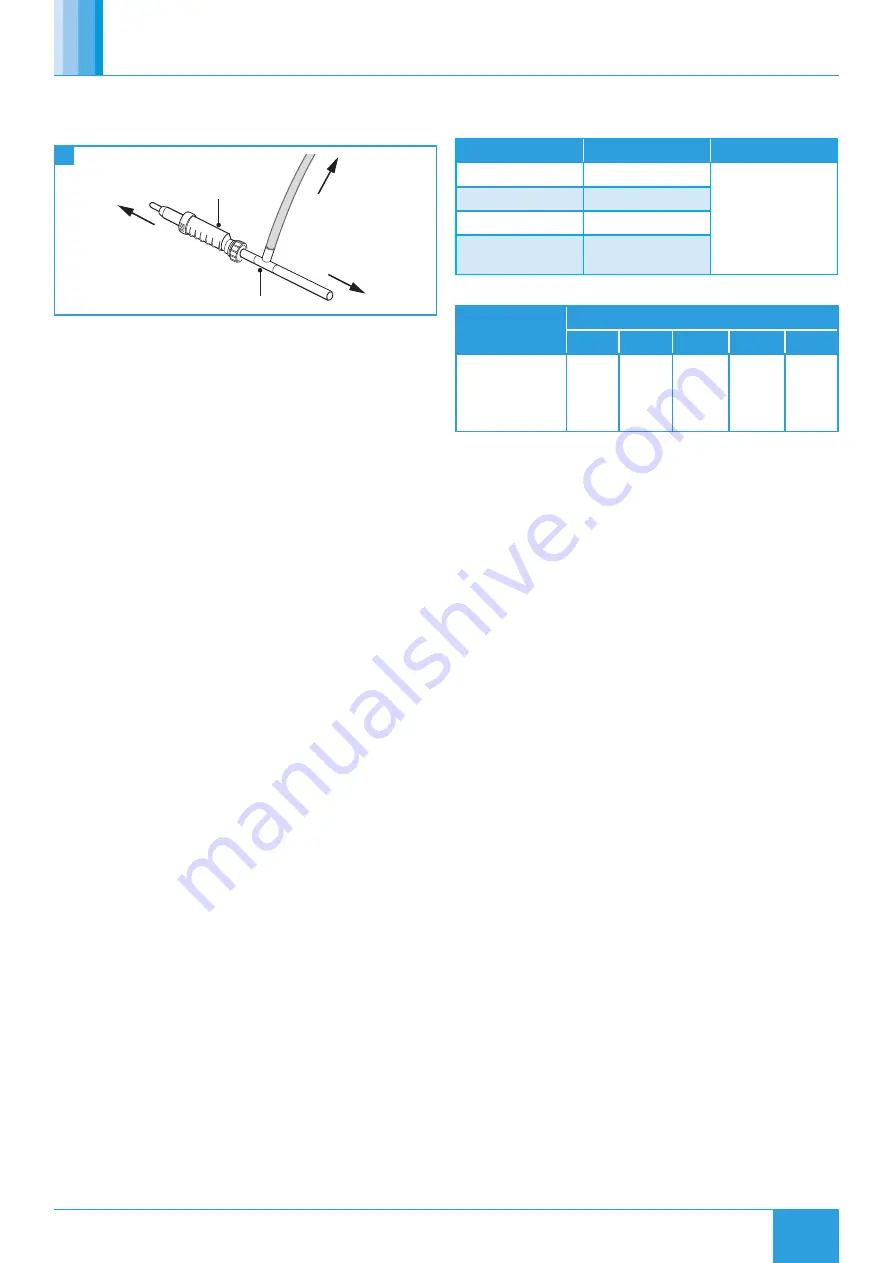

When using a “T” Piece to connect the CONTRAP drainage and

the MVHR drain pipework the MVHR drain must always be fitted

before the “T” Piece.

10

Condensate Drain "T" Piece Installation

To SVP

“T” piece

MVHR Drain

To unit

To CONTRAP

3.4 Extract & Supply Areas

The unit is designed to extract air from all wet rooms e.g. bathroom,

kitchen, en-suite, utility room (with sink). WC’s do not need to be

ventilated if openable windows are fitted.

Supply air should be to all habitable rooms e.g. bedrooms and lounge.

Extract / input grilles should be adjustable valve types (not supplied).

External grilles are to have a minimum free area of 12,250 mm

2

.

3.5 Ducting

Before commencing ducting installation reference should be made

to building regulations document “Domestic ventilation compliance

guide”. This document supports ADF2010 and details installation,

testing and commissioning of all ventilation systems.

If the enclosure is to be used in conjunction with an ancillary

distribution box (MRXBOX-DB2) refer to additional assembly

instructions supplied with the MRXBOX-DB2 as requirements will

differ.

Otherwise fit 4x 125mm diameter plastic spigots with the self-tapping

screws supplied to the spigot fixings plates found on the top panel of

the enclosure, a bead of silicone should be applied to the groove of

spigot fixing plate to prevent leakage (Figure 3).

It is recommended that rigid ducting be used at all times. Flexible

ducting has a very high resistance and it is impossible to calculate how

much resistance will be on a system if used.

If used the flexible ducting must be kept to a minimum and should

always be pulled taut. A maximum of 300mm should be used on each

leg.

To prevent condensation on the outside of the outside air inlet duct and

the air outlet duct from the unit, these ducts should be insulated.

Ducting must be installed in such a way that resistance to airflow is

minimised. Bends should be kept to a minimum.

A minimum distance of 300mm between the appliance and any bends

in ductwork is recommended.

Ideally 125mm diameter or 220 x 90mm rectangular ducting should

be used (Refer to dwelling design drawing, Figures 12 & 13 for further

information).

Ducting joints must be sealed with silicone type sealant and shall be

adequately and reliably fixed to the appliance.

Any air intake terminal MUST be installed in accordance with the

appropriate regulation.

As a guide, the BS5440 series of British Standards deals with this

issue and currently states that an air intake must be at a minimum

distance of 300mm from a gas boiler balanced flue.

Installers are advised to be aware of the requirements of this

standard when installing ‘through the wall’ supply air ducting.

3.6 Ventilation Flow Rates

3.6.1 ADF 2010 - Extract Ventilation Rates

Room

Min high rate

Min low rate

Kitchen

13 l/s

Total extract rate

should be at least

the whole dwelling

ventilation rate given

in table 2.

Utility Room

8 l/s

Bathroom

8 l/s

Sanitary

Accommodation

6 l/s

3.6.2 Whole Dwelling Ventilation Rates

Number of bedrooms in dwelling

1

2

3

4

5

Whole dwelling

ventilation rate

(l/s)

1,2

13

17

21

25

29

1. In addition, the minimum ventilation rate should be no less than

0.3 l/s per m2 of internal floor area. (This includes all floors, e.g.

for a two-story building add the ground and first floor areas).

2. This is based on two occupants in the main bedroom and a single

occupant in all other bedrooms. This should be used as the default

value. If a greater level of occupancy is expected add 4 l/s per

occupant.

3.7 ADF 2010 Ventilation Calculations Design Of MVHR

Systems

The MVHR system has been sized for the winter period. Additional

ventilation may be required during the warmer months and it has

been assumed that the provisions for purge ventilation (e.g. openable

windows) could be used.

Step 1:

For any design air permeability, determine the whole dwelling

ventilation supply rate from

Table 2.

As an alternative where the design air permeability is intended to be

more than (>) 5m3/(h.m2) 50 Pa, allow for infiltration for all dwelling

types by subtracting from the whole dwelling ventilation supply rate

from Table 2;

0.04 x gross internal volume of the dwelling heated

space (m3).

Step 2:

Calculate the whole dwelling extract ventilation rate by

summing the individual room rates for ‘minimum high rate’

from Table

1.

(For sanitary accommodation only, as an alternative, the purge

ventilation provisions given in ADF 2010 can be used where security is

not an issue. In this case ‘minimum high extract rate’ for the sanitary

accommodation should be omitted from the step 2 calculation).

Step 3:

The required airflow rates are as follows:

•

The maximum whole dwelling extract ventilation rate (e.g. boost)

should be at least the greater of step 1 and step 2. Note that the

maximum individual room extract rate should be at least those

given in

table 1.

•

The minimum air supply rate should be at least the whole building

ventilation rate found in step 1.

For Scotland refer to BRE Digest 398.

For further information refer to “Domestic Ventilation Compliance

Guide” www.planningportal.gov.uk/buildingregulations/approved

documents/partl/compliance