2

05. 11. 21. Document Number 671999

Nuaire | Western Industrial Estate | Caerphilly | CF83 1NA | nuaire.co.uk

MRXBOXAB-ECO-LP2B

Installation Manual

2.0 INTRODUCTION

The LP2 ceiling void mounted unit is designed to provide mechanical

supply and extract ventilation with heat recovery and incorporates HX

bypass.

The unit is fitted with two independent fans. Each fan has full speed

control for background and boost ventilation rates. To recover heat

from the extract air the heat exchanger block is utilised. The heat

exchanger can recover up to 80% of the normally wasted heat.

The unit must remain switched on at all times to maintain

ventilation within the dwelling. Turning the unit off will cause long

term damage to the unit and building fabric.

This appliance is not intended for use by persons (including

children) with reduced physical, sensory or mental capabilities,

or lack of experience and knowledge, unless they have been given

supervision or instruction concerning the use of the appliance by a

person for their safety. Children should be supervised so that they

do not play with the appliance.

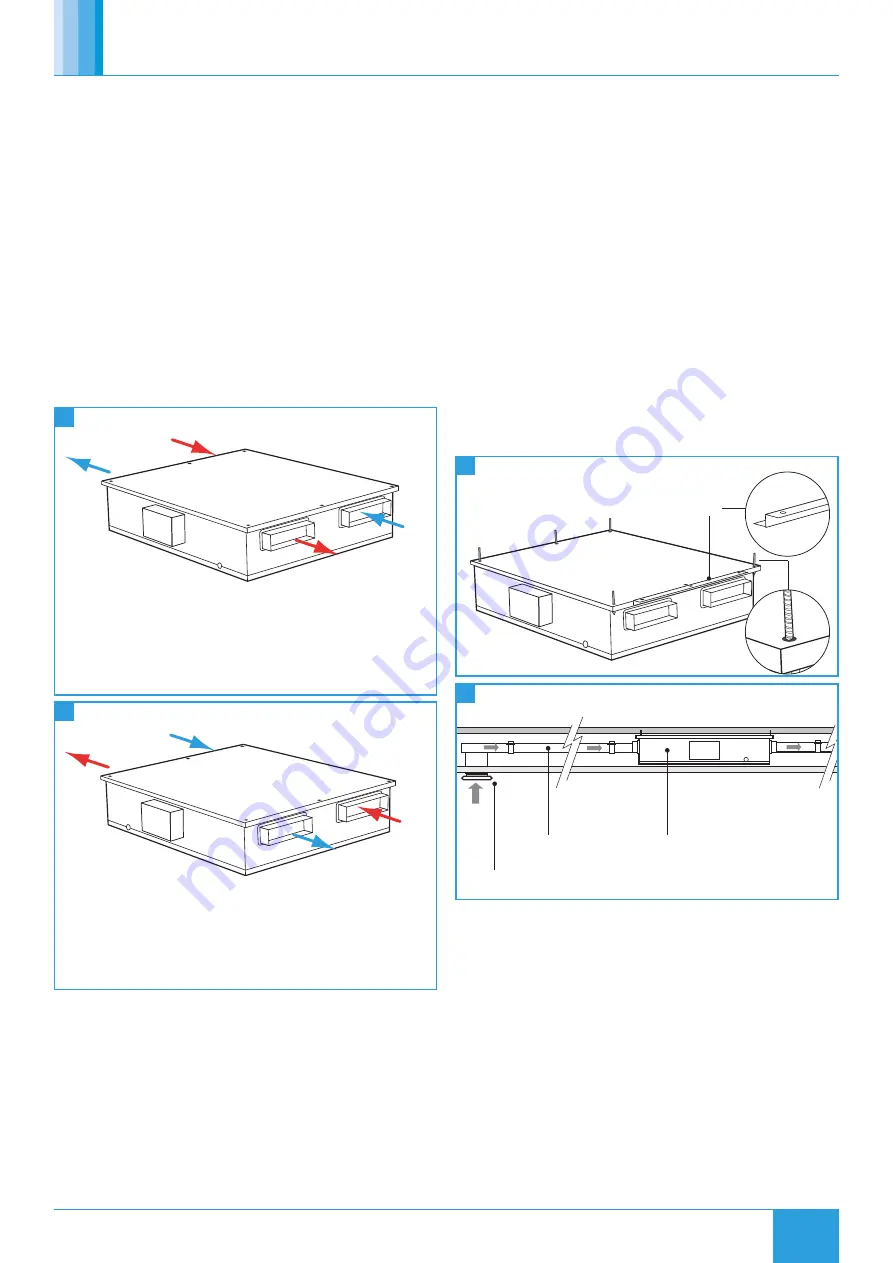

Spigots 1 to 4

1. Intake Air (Fresh air from outside).

2. Supply Air (Supply in to house).

3. Extract Air (Warm stale air from house).

4. Exhaust Air (Waste air to oustide).

Spigot 1.

Spigot 4.

Spigot 3.

Spigot 2.

1

Unit Airflow Paths (Standard Unit Configuration)

Spigot 3.

Spigot 2.

Spigot 1.

Spigot 4.

Spigots 1 to 4

1. Intake Air (Fresh air from outside).

2. Supply Air (Supply in to house).

3. Extract Air (Warm stale air from house).

4. Exhaust Air (Waste air to oustide).

2

Unit Airflow Paths (Opposite Hand Unit Configuration)

3.0 MECHANICAL INSTALLATION

Installation must be carried out by competent personnel in accordance

with the appropriate authority and conforming to all statutory

governing regulations. All mains wiring must be in accordance with the

current I.E.E. Regulations, or the appropriate standards. Ensure that the

mains supply (Voltage, Frequency and Phase) complies with the rating

label.

Please note a clear working space is required around the installed unit

to allow the cover to be removed and provide sufficient access for

maintenance such as filter change.

The fan must be installed indoors, in a suitable ceiling void away from

direct sources of frost, heat, water spray or moisture generation. For a

vibration-free result the unit must be mounted to a solid surface in the

void.

The unit is designed for ceiling mounting only (Horizontal surface).

The unit is supplied with a steel mounting bracket.

Position & secure the steel bracket to the ceiling using appropriate

fixings (supplied by others), ensuring that the two outer fixing holes on

the unit are accessible (Figure 3).

The mounting bracket should be on the same side as the

condensate take off.

3. The unit can now be offered into position & located into the

mounting bracket.

4. Using appropriate fixings (supplied by others) fix the unit to the

ceiling. It is recommended that the unit is fixed through three holes on

the non-bracket side and the two outer holes on the bracket side.

The unit must be installed in an upright position as shown for

the condensate drain and for compliance with safety regulations

relating to IP protection for water drip ingress.

Steel mounting bracket

3

Standard Unit Mounting Using Appropriate Fixing Bolts

ducting in

204 x 60mm

ceiling void.

in ceiling.

Side view of unit

mounted in the ceiling void.

Air valve

4

Side View Of Standard Unit Typical Ceiling Void Installation

Using 204 x 60 mm Rectangular Ducting & Air Valves

3.1 Condensate Drain Installation

•

Unit comes complete with external drain pipe (21.5mm waste

pipe). Use conventional plumbing connections to link up with

U-trap or alternative drain method (Solvent cement connections

or compression fit connections are recommended). The

condensate must be discharged under a water level in a U-trap

drainpipe or an alternative drain method which acts as an airlock.

•

This condensate discharge connection is suitable for 21.5mm dia.

overflow pipe. Solvent cement should be used to make the joint.

•

If using a U-trap please ensure the U-trap has been filled to a

suitable level of water to avoid any air locks.

•

If the condensation pipe is fitted in an unheated space the pipe

should be in insulated to prevent freezing.

Nuaire recommend MVHR-DRAIN be used as the primary condensate

take-off (Figure 5 and 6).