5

30. 06. 20. Document Number 671948

Nuaire |

Western Industrial Estate

|

Caerphilly

|

CF83 1NA

|

nuaire.co.uk

XBC+ with Ecosmart Classic (E) or No (N) Control

Installation Manual

3.4 Condensate Pump

3.4.1 Condensate Pump Alarm

The condensate pump incorporates an alarm function. If the water

level in the condensate tray exceeds a maximum level (for example, as

a result of the discharge tube becoming blocked or frozen), the alarm

contact will open. This contact is internally connected to the heat

exchanger bypass actuator, and the unit will automatically be placed

into bypass mode, preventing further condensate production. Unit

operation will otherwise be unaffected.

3.4.2 Condensate Pump Specification

Maximum flow rate = 12 l/h

Maximum head = 20m Vertical, 100m Horizontal

Pipe Connection size (Condensate) XBOXER XBC = 8 mm

LPHW Coils, if fitted, are tested during manufacture to 16 Bar (using

dry compressed air). Coil and valve assemblies are similarly tested to 10

Bar. The operation of standard equipment is rated to PN6.

Electrical connections to the unit shall be made in accordance with

the appropriate product and installation wiring diagrams provided, and

shall use appropriately sized and rated cables.

Only the prepared apertures in the unit casing may be used for cable

entry. Do not drill or cut the unit casing for this purpose. Cable access

points are provided at the ends of the control enclosure.

If the control is rotated to aid connection of cables, please ensure that

sufficient flexibility is provided in the final connection run.

To avoid conflict with the unit access panels, it is recommended

that electrical and plumbing service connections to the unit are run

at 90 degrees to the main air flow axis.

Control circuit connections must be segregated (i.e. routed separately)

by a minimum of 50mm from power connections.

The unit rating label shows the maximum electrical load of the

equipment. Connections to the unit may include single phase supply

connections, and a variety of control circuits.

Only the prepared apertures in the unit casing may be used for cable

entry. Do not drill or cut the unit casing for this purpose.

The equipment must be earthed and earth-bonded. Means of local

isolation for maintenance purposes are generally required (by others).

Ensure that all mains connections are isolated.

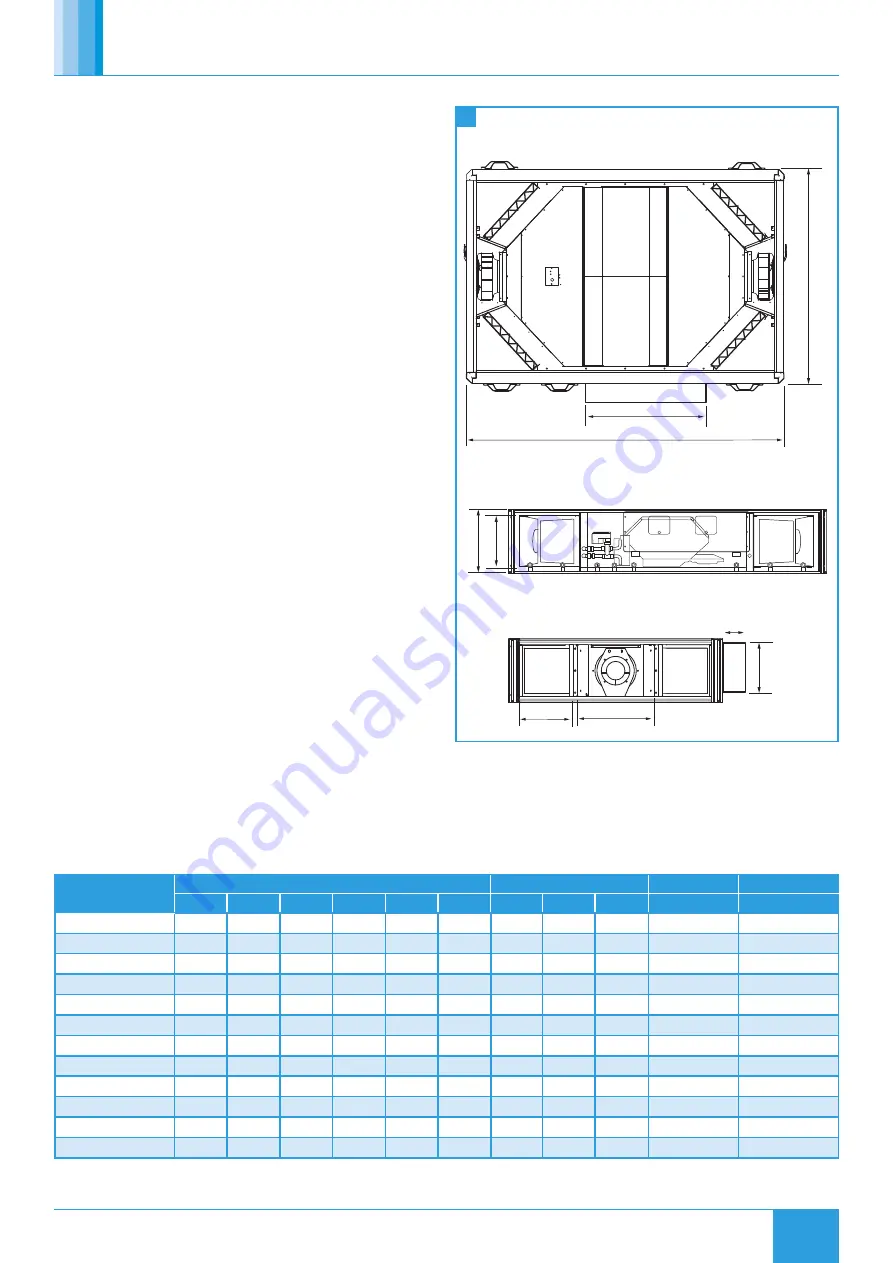

Plan view

Side view

End view

K

M

J

E

F

G

A

B

C

Plan view

Side view

End view

K

M

J

E

F

G

A

B

C

9

Unit Dimensions & Weights

3.5 Dimensions & Weights

†

2 attenuator flange connections are attached to every unit. Add 60mm to dimension 'A' to include both flanges for standard (no roof)

units.

Unit Code

Unit Dimensions (mm)

Control Dimensions (mm)

Unit Weights

Packed Weights

A

†

B

C

J

K

M

E

F

G

(kg)

(kg)

XBC10HA-***-***

1600

1000

260

238

220

347

130

210

640

195

261

XBC10HA-***-**W

1898

1210

335

238

220

347

210

230

674

217

283

XBC15HA-***-***

1600

1000

260

238

220

347

130

210

640

195

261

XBC15HA-***-**W

1898

1210

335

238

220

347

210

230

674

217

283

XBC25HA-***-***

1713

1160

340

252

302

471

130

210

640

242

308

XBC25HA-***-**W

1984

1390

426

252

302

471

276

287

820

267

333

XBC45HA-***-***

1912

1262

400

270

360

531

130

210

640

298

405

XBC45HA-***-**W

2204

1490

487

270

360

531

276

287

954

328

435

XBC55HA-***-***

1900

1560

470

397

430

587

130

210

640

375

546

XBC55HA-***-**W

2204

1796

571

397

430

587

215

386

1000

410

581

XBC65HA-***-***

1913

1572

620

398

580

588

130

210

640

476

652

XBC65HA-***-**W

2204

1796

725

398

580

588

215

514

1000

514

690