Version 1.0

NS102521

7

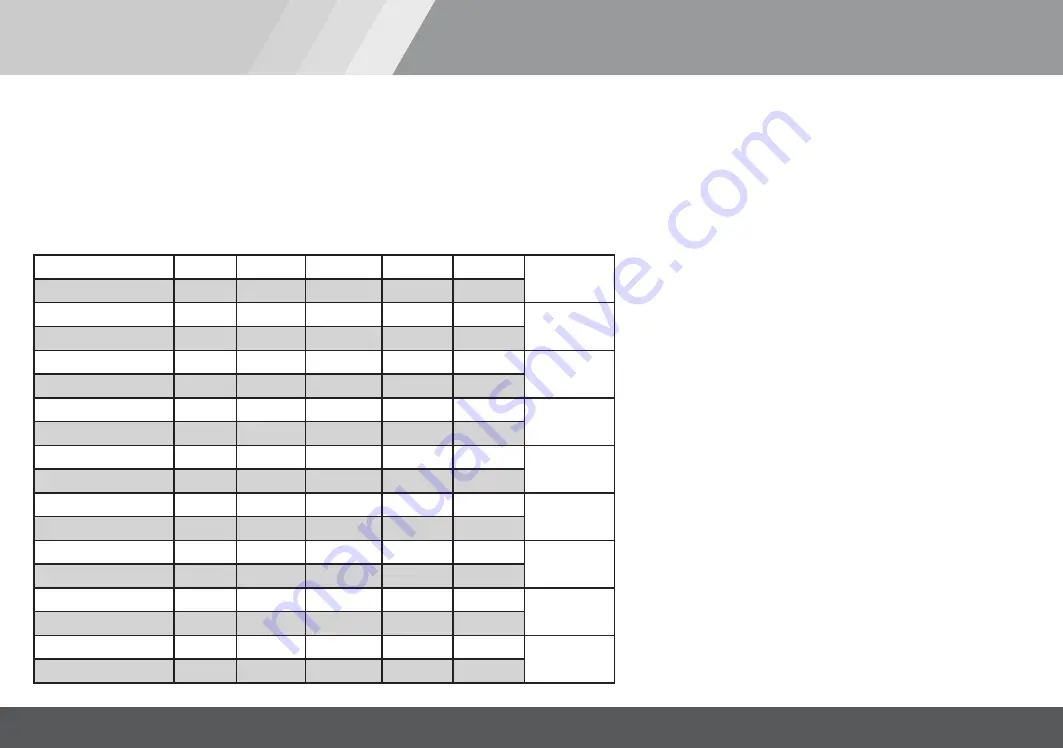

PSI ON Material

500

750

1000

1250

1500

One 3.5G

Bag (BTS)

Gauge Reading

258

387

516

645

774

PSI ON Material

500

750

1000

1250

1500

Two 3.5G

Bags (BTS)

Gauge Reading

515

774

1031

1289

1547

PSI ON Material

500

750

1000

1250

1500

Three 3.5G

Bags (BTS)

Gauge Reading

773

1160

1547

1934

2321

PSI ON Material

500

750

1000

1250

1500

One 7G

Bag (BTS)

Gauge Reading

459

687

917

1146

1375

PSI ON Material

500

750

1000

1250

1500

Two 7G

Bags (BTS)

Gauge Reading

917

1375

1834

2292

2751

PSI ON Material

500

750

1000

1250

1500

Three 7G

Bags (BTS)

Gauge Reading

2751

4126

5502

6877

8253

PSI ON Material

500

750

1000

1250

1500

One 14G

Bag (BTS)

Gauge Reading

716

1075

1432

1791

2149

PSI ON Material

500

750

1000

1250

1500

Two 14G

Bags (BTS)

Gauge Reading

1433

2149

2865

3582

4298

PSI ON Material

500

750

1000

1250

1500

Four 14G

Bags (BTS)

Gauge Reading

2865

4298.65

5731.54

7164

8598

NugSmasher® extraction bags, our bags are recommended or

optimal yield and clean quality rosin. NugSmasher® extraction

bags are specifically designed to work with the weight of fresh

cured flower together with our extraction machines and are

labeled accordingly at: 3.5g, 7g and 14g this assumes the bags

are loaded (BTS) or bottle/barrel-tech style (upright so that

you end up with the round coin like puck once fully pressed).

This perfected method allows you the ability to put the proper

eight of flower into the bag and get a consistent extraction

very time. The reason for this is that it allows for the proper

pounds per square inch, pressure (PSI) on your product and

eliminates the guess work.

3.5g = 1.5” Diameter = 1.77” in surface area

7g = 2”-2.2”Diameter= 3.14” in surface area

14g=2.4”-2.7”Diameter= 4.91” in surface area.

We prefer to use 160 micron for fresh flower, as flower dries we

go down in micron screen size (for dry flower use 90 micron).

NOTE: As the micron gets smaller the diameter get slightly larger.

Example: 90 micron is about 5% larger at the end of your extraction.

For the ProTouch Calculator tool, please visit,

NugSmasher.com/tools

Plate Pressure:

The applied plate pressure is determined by the extracted material’s

surface area (bag, size and quantity) and the applied pressure to

the extraction (Gauge PSI Reading)

Gauge Pressure:

Gauge pressure (psi) is measured from the hydraulic rams fluid

pressure. This is the applied pressure and should be adjusted to the

surface area to achieve optimum results.

Plate Pressure:

Gauge Pressure:

Surface Area Key

-VS-

pressure System

NugSmasher® ProTouch Consistency Chart PSI to Surface Area Bag Selection

Summary of Contents for ProTouch

Page 13: ...Version 1 0 NS102521 rosin made simple ...

Page 14: ......

Page 15: ......

Page 16: ......