18

T 01460 68600

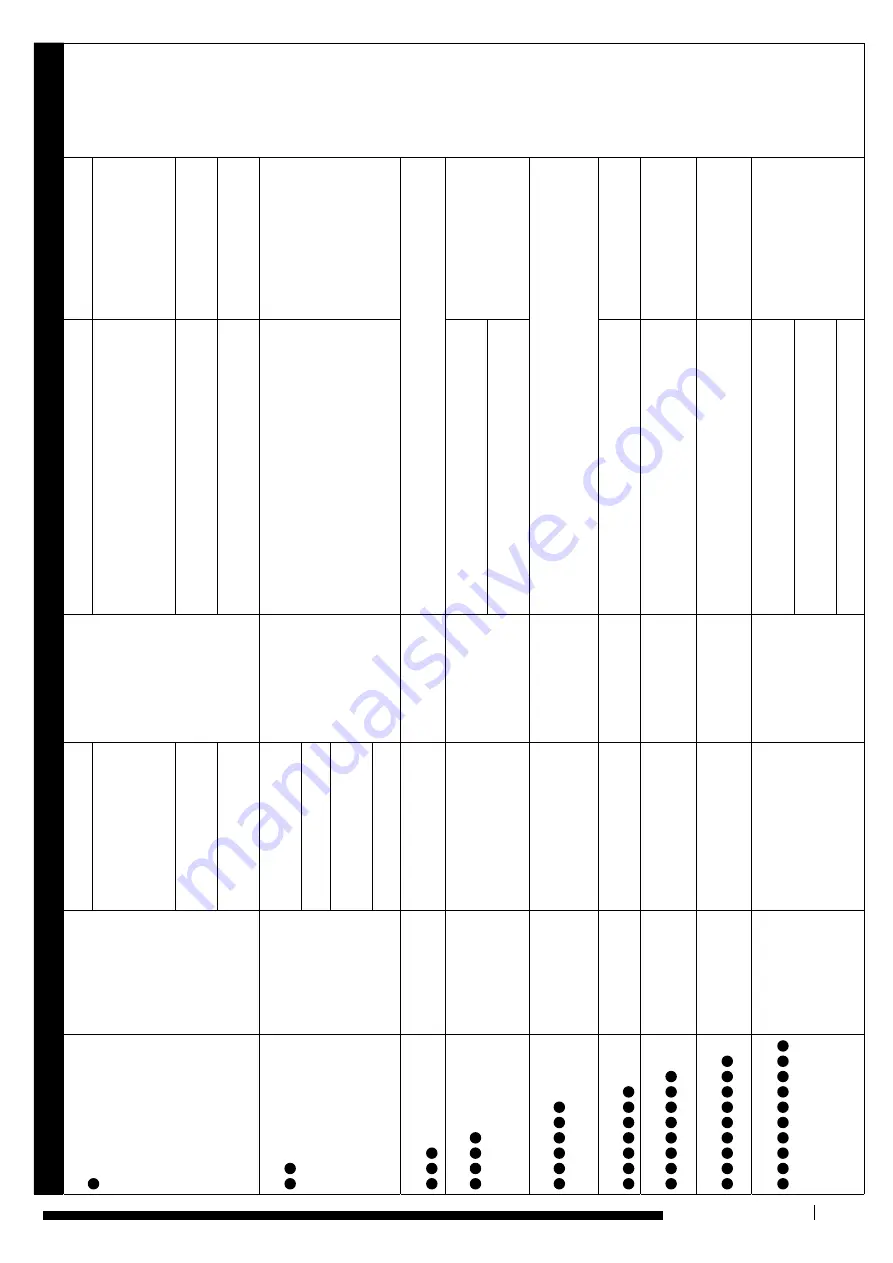

Gr

een Status Indicator

Fault

Possible Cause

Effect on Pr

oduct

Investigate the Following

Action Requir

ed

If Fault Persists

1 Flash with pause

Batteries voltage low

Batteries not been charged

Operating time sever

ely r

educed

or machine will not operate

Check when machine last charged

Charge batteries immediately

Possible bad connection between batteries, contr

oller

,

charger or fuses caused by loose connections, damaged wiring, water ingr

ess

Switch OFF the machine : Remove Fuses Check connections to batteries, charger and fuses for loose wir

es or scr

ews

Tighten loose connections and r

eplace damaged

components

Not accepting charge due to faulty battery / cell

Check each battery V

oltage individually to detect defect

unit 10.5V min

Replace batteries as r

equir

ed

Charger not functioning

Check battery voltage and charge curr

ent ensuring

charger r

ed fault light is extinguished

Replace charger

2 Flashes with pause

Traction motor disconnected

The motor has a bad connection

The motor will not operate

Check all connections and leads between motor and contr

oller

Tighten loose connections and r

eplace damaged

components

Motor disconnected

TCO activated (Thermal Cut Out)

Motor failed to open cir

cuit

3 Flashes with pause

Traction motor wiring trip

The motor has a short cir

cuit

to a battery

Motor will not operate

Check all connections and leads between the motor and contr

oller

4 Flashes with pause

Battery Lockout

The battery charge level has fallen below the battery lockout level and the contr

oller

is inhibiting machine functions

Machine functions not working

Check battery voltage and charge curr

ent ensuring

charger r

ed fault light is extinguished

Charge batteries immediately

Check each battery voltage individually to detect defect unit 10.5V min

6 Flashes with pause

Charger connected

The contr

oller is being inhibited

from driving, this may be because the battery charger is connected

Machine functions not working

Remove charger to operate machine

7 Flashes with pause

Machine inhibited

E-Stop pr

essed

Machine functionality inhibited

Check E-Stop

Release E-Stop and cycle key switch

8 Flashes with pause

Contr

oller trip

A contr

oller trip is indicated

Machine functions not working

Check all connections and leads

Tighten loose connections and r

eplace damaged

components

9 Flashes with pause

Brake deactivated or failed

Poor brake connections Brake failur

e or deactivation

Traction drive disabled

Check brake wiring and brake lever

Replace brake or wiring as necessary

. Reactivate brake

by engaging brake lever

10 Flashes with pause

High battery voltage

Poor connections between battery contr

oller and traction

motor

Machine functions not working

Check each battery V

oltage individually to ensur

e

voltage < 14 volts

Check connections on contr

oller batteries and traction

motor

Check combined battery pack voltage is < 28 volts

Contact Service Agent

Summary of Contents for TGB 6055/100

Page 24: ...24 T 01460 68600 EU Declaration of Conformity...

Page 25: ...25 T 01460 68600 Warranty...

Page 26: ...26 T 01460 68600 Notes...

Page 27: ...27 T 01460 68600 Notes...