22

www.numatic.co.uk

Spare Parts

Part No.

SQUEEGEE

Part No.

BRUSHES

904691

Complete 650mm Squeegee Assembly Red Trim

TGB

2120

606028

550mm Polyscrub Brush

900518

Squeegee Blade Set - Serilor Pu Green Fr & Rr

TGB

2120

606550

550mm Nyloscrub Brush

208497

Squeegee Castor

900526

500mm Nuloc2 Drive Board

206953

Detent Pin

903994

370mm Nyloscrub Brush (2 required)

208796

Squeegee Buffer Wheel

903449

370mm Polyscrub Brush (2 required)

604013

Squeegee Lift Inner Cable Kit

900524

360mm Nuloc2 Drive Board (2 required)

208156

M6 Pinch Bolt

Part No.

PUMP AND FILTER

903853

Complete 750mm Squeegee Assembly Red Trim

TGB

2128

230278

Water Pump

904699

Squeegee Blade Set - Serilor Pu Green Fr & Rr

TGB

2128

208888

Extended Filter Complete Assembly

Part No.

TOP TANK

208827

Strainer Black Top

903542

Grit Filter Basket

208889

Extended Strainer 50 Mesh Screen

208861

Air-Filter

208830

Strainer Gasket

208980

TGB

Foam Pad

208890

68Mm Extended Strainer Clear Bowl

304503

Separator Seal Strip 1045Mm Long

Part No.

BOTTOM TANK AND STEERING COLUMN

208862

Seat Pad

237685

Bottom Tank Scuff Moulding Left Hand

208864

Back Pad

237684

Bottom Tank Scuff Moulding Right Hand

208867

Beacon Light

303942

Deck Buffer Wheel

TGB

2120

208907

Gas Strut (100Nm)

208985

Lift Handle Nylon Guider

Part No.

HOSES

392438

Bottle Plate

208188

Squeegee Suction Hose

208897

Steering Drive Belt

237718

3 Ring Hose Guide

204120

Front Wheel

208938

Bottom Tank Dump Hose

901209

Rear Wheels

902468

Top Tank Dump Hose c/w Adjustable Cuff

237609

Splash Skirt

TGB

2120

206842

Filler Stretch Hose

204068

Deck Buffer Wheel CRO8072

903437

Splash Skirt

TGB

2128

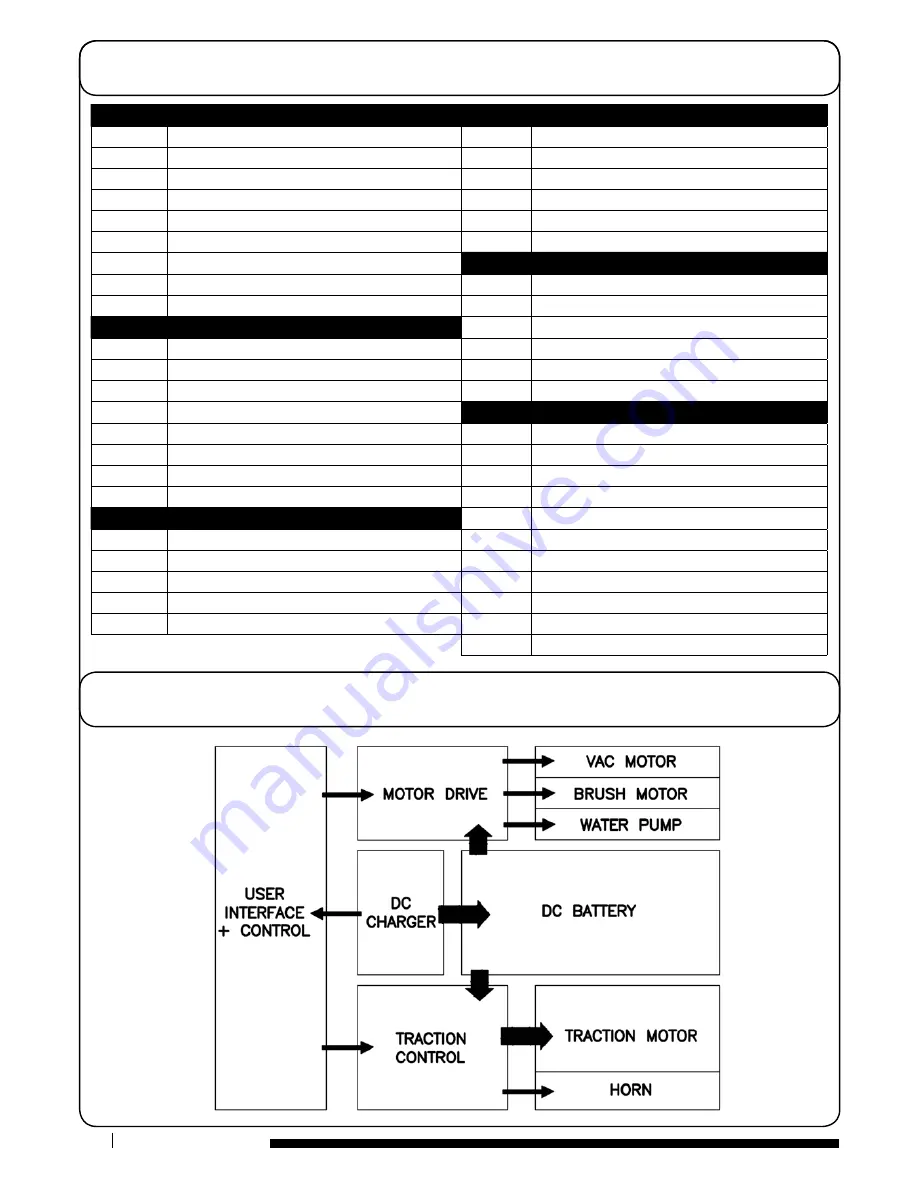

Schematic Diagram