Machine set-up guide

6

www.numatic.co.uk

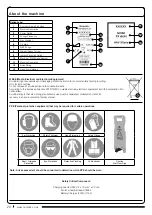

The U-bend in the hose prevents water spillage when the vacuum is switched off.

Refit vacuum hose to the floor tool when finished.

Hose U-bend clip

Fitting Dump Hose

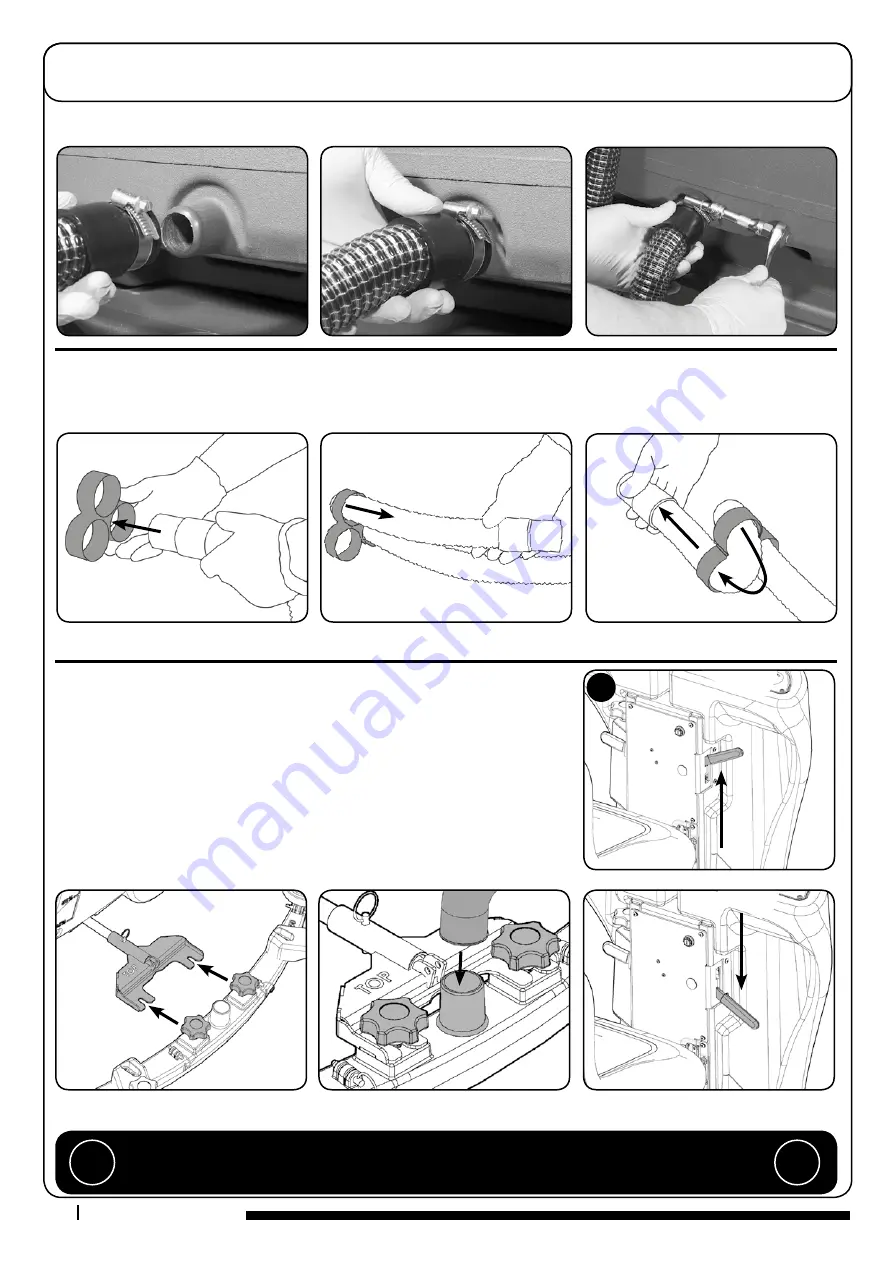

NOTE: DO NOT push the vacuum hose onto the floor tool with the floor tool in the raised position.

Slide floor tool onto bracket.

Tighten retaining knobs to finger tight

and attach hose.

Raise the floor tool.

The floor tool design incorporates a safety knock-off feature, this allows it to safely

disengage from its mounting should it become caught on an obstruction during

forward movement.

Please ensure you do not over tighten the retaining knobs.

Break-away floor tool

Fitting the floor tool

NOTE: Raise floor tool before driving to the cleaning area.

The machine will not operate in reverse with the floor tool lowered.

Lower the floor tool.

Lower the floor tool arm by moving the release lever to the upper position (Fig.1).

1

NOTE: MACHINE WILL NOT REVERSE WITH FLOOR TOOL IN THE LOWERED POSITION.

!

!

7MM