15

Only use brushes provided with the appliance or those specified in the instruction manual.

The use of other brushes may impair safety.

A full range of brushes and accessories are available for this product.

Only use brushes or pads which are suitable for the correct operation of the machine for the specific task being

performed.

It is essential that this equipment is correctly assembled and operated in accordance with current safety regulations.

When using the equipment always ensure that all necessary precautions are taken to guarantee the safety of the

operator and any other persons who may be affected.

Wear non-slip footwear when scrubbing. Use a respiratory mask in dusty environments.

When cleaning, servicing or maintaining the machine, replacing parts or converting to another function the power

source shall be switched off.

Mains operated machines shall be disconnected by removing the power plug, and battery operated machines shall be

disconnected by switching off the isolating key.

Machines left unattended shall be secured against unintentional movement.

Operators shall be adequately instructed as to the correct use of the machine.

When detergents or other liquids are used, read the manufacturer’s instructions.

Do not allow the supply cord to come into contact with the rotating brushes.

When detergents or other liquids are used, read the manufacturer’s instructions.

Do not allow the supply cord to come into contact with the rotating brushes.

WARNING

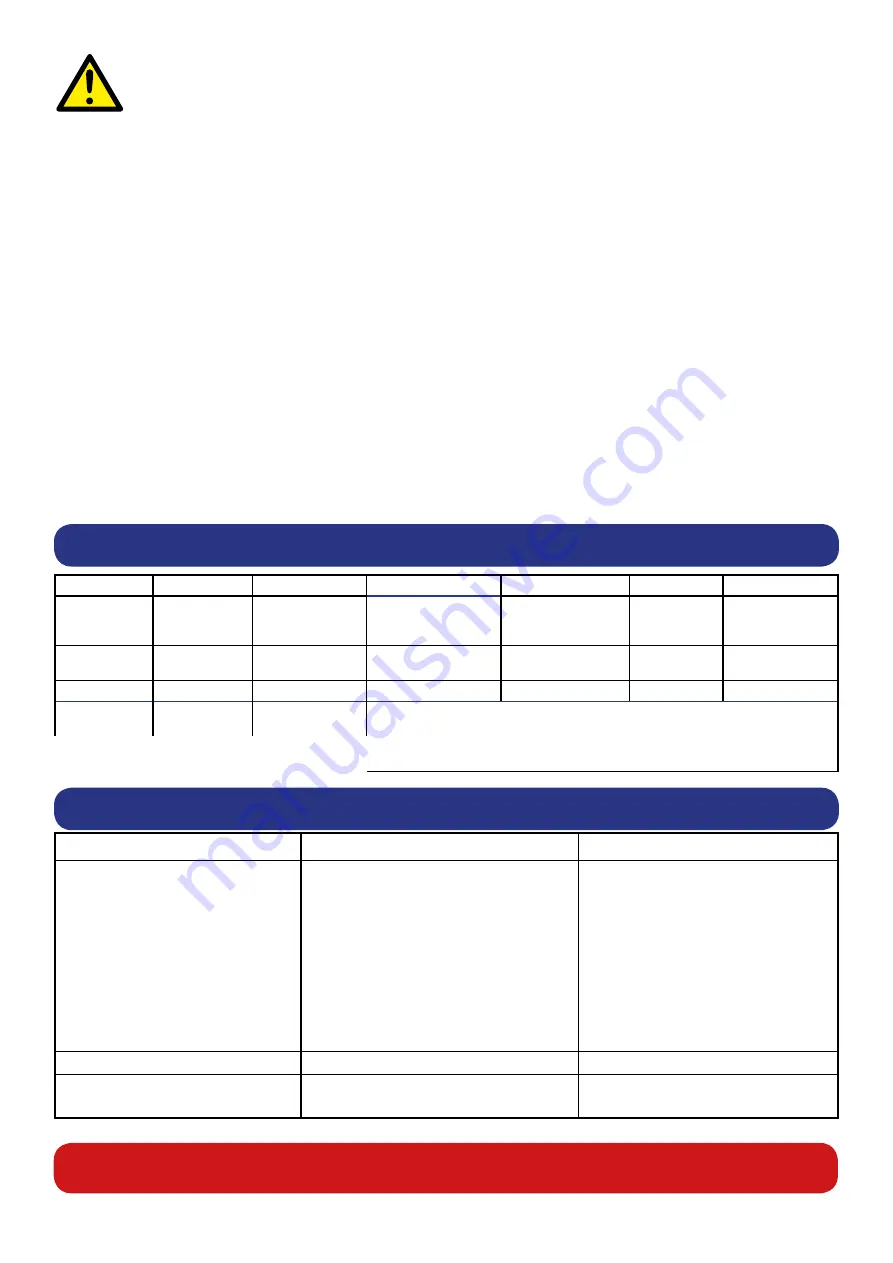

Data

Brush Motor

Vac Motor

Power

Noise

Speed

Brush

Dimensions

400 W

300 W

220-240v 50/60 Hz

115v 50Hz

71 dB(A)

50Hz = 150rpm

400 mm

Width - 520 mm

Length - 880 mm

Height - 1132 mm

Gross Weight

Full

Protection

Class

Hand Arm

Vibration

Pad

Net Weight

Cleaning

Range

Water Capacity

56.5 Kg

IPX 4

1.4 +/- 0.06ms²

360 mm

38.5 Kg

42 m

18 L

Fluid Flow

tap @40

0

Brush / Pad

Pressure

Cleaning Speed

0.35 LPM

27.4 / 26.2

G/ cm

2

0-4.2 Kph

Failure to rectify the problem or in the event of a breakdown contact your

Numatic dealer or the Numatic Technical help line +44 (0)1460 269268

PROBLEM

CAUSE

SOLUTION

Poor water pick-up

Waste-water tank full

Clogged / blocked vacuum hose

Loose hose connections

Debris basket filter clogged/blocked

Separator filter clogged / blocked

Poor separator seal

Damaged separator seal

Damaged / split vacuum hose

Damaged floor-tool blades

Empty waste-water tank

Remove and clean

Push tight connections

Remove and clean

Remove and clean

Clean and refit

Renew (contact service dept)

Renew (contact service dept)

Renew (contact service dept)

No brush / scrub function

No brushes fitted

Check and fit

Little or no water flow

Clean-water tank empty

Clean-water tank filter blocked/ clogged

Fill clean-water tank

Remove and clean

Trouble-Shooting

Summary of Contents for TT 1840

Page 17: ...17 TT 1840 220v 240V 115V DRW 13476 A01 19 03 2013...

Page 18: ...18...