09

08

NON-MARRING PAD

The non-marring pad attached to the nose of the

tool helps prevent marring and denting when

working with softer woods.

Make sure there is no fastener in

magazine before clearing a jam.

WARNING:

!

Disconnect the tool from the air source

whenever clearing a jam. After

disconnecting the tool from the air

compressor, there should still be enough

air pressure to fire the tool. After the air

hose is disconnected, always fire the tool

into scrap wood repeatedly to make sure

all of the compressed air is expended.

WARNING:

!

Disconnect the tool from the air resource

before removing or replacing the non-

marring pad. Failure to do so could result

in serious personal injury.

WARNING:

SETTING THE AIR PRESSURE

The amount of air pressure required depends on

the size of the fasteners and the workpiece material.

Begin testing the depth of drive by driving a test nail

into the same type of workpiece material used for

the actual job.Drive a test fastener with the air

pressure set at 90-95psi. Raise or lower the air

pressure to find the lowest setting that will perform

the job with consistent results.

It may be possible to achieve the desired depth with

air pressure adjustments alone.

Always know the operational mode of the

tool before using. Failure to know the

operational mode could result in death or

serious personal injury.

WARNING:

!

FIRING THE TOOL

This mode requires the trigger to be pulled each

time a fastener is driven. The tool can be actuated

by depressing the WCE against the work surface

followed pulling the trigger.

The trigger must be released to reset the tool before

another fastener can be driven.

An improperly functioning tool must not

be used. Do not actuate the tool unless the

tool is placed firmly against the work

place.

WARNING:

!

WORK CONTACT ELEMENT (WCE)

Disconnect the air supply from the tool.

Remove all fasteners from the magazine.

Make sure the trigger and work contact element

move freely up and down without sticking or

binding.

Reconnect air supply to the tool.

Depress the work contact element against the

work surface without pulling the trigger. The tool

must not operate. Do not use the tool if it

operates without pulling the trigger. Personal

injury may result.

Remove the tool from the work surface. The

work contact element (WCE) must return to its

original down position. The tool must not

operate. Do not use the tool if it operates while

lifted from the work surface. Personal injury may

result.

Pull the trigger and depress the work contact

element(WCE) against the work surface. The

tool must not operate.

Depress the work contact element (WCE)

against the surface. Pull the trigger. The tool

must operate.

⒈

⒉

⒊

UNLOADING FASTENERS

Unloading is the reverse of loading. Always

disconnect the air source before unloading.

Always unload all fasteners before removing

tool from service.

WARNING:

!

Always disconnect the air source before

unloading.

WARNING:

!

⒋

⒌

⒍

⒎

⒏

Check the operation of the work contact

element trip mechanism before each use.

The WCE must move freely without

binding through its entire travel distance.

The WCE spring must return the WCE to

its fully extended position after being

depressed. Do not operate the tool if the

WCE trip mechanism is not operating

properly. Personal injury may occur.

CAUTION:

MAINTENANCE

Any time inspection, maintenance, and

cleaning are done:

Disconnect the tool from the air source.

Empty the magazine completely.

◆

◆

WARNING:

!

Each tool is packed with an anti-dust cap on the air

connector.

Keep the anti-dust cap cover on the air connector

when the tool is not in use.

ANTI DUST

-

MODEL: SST9032

MODEL: SST9032

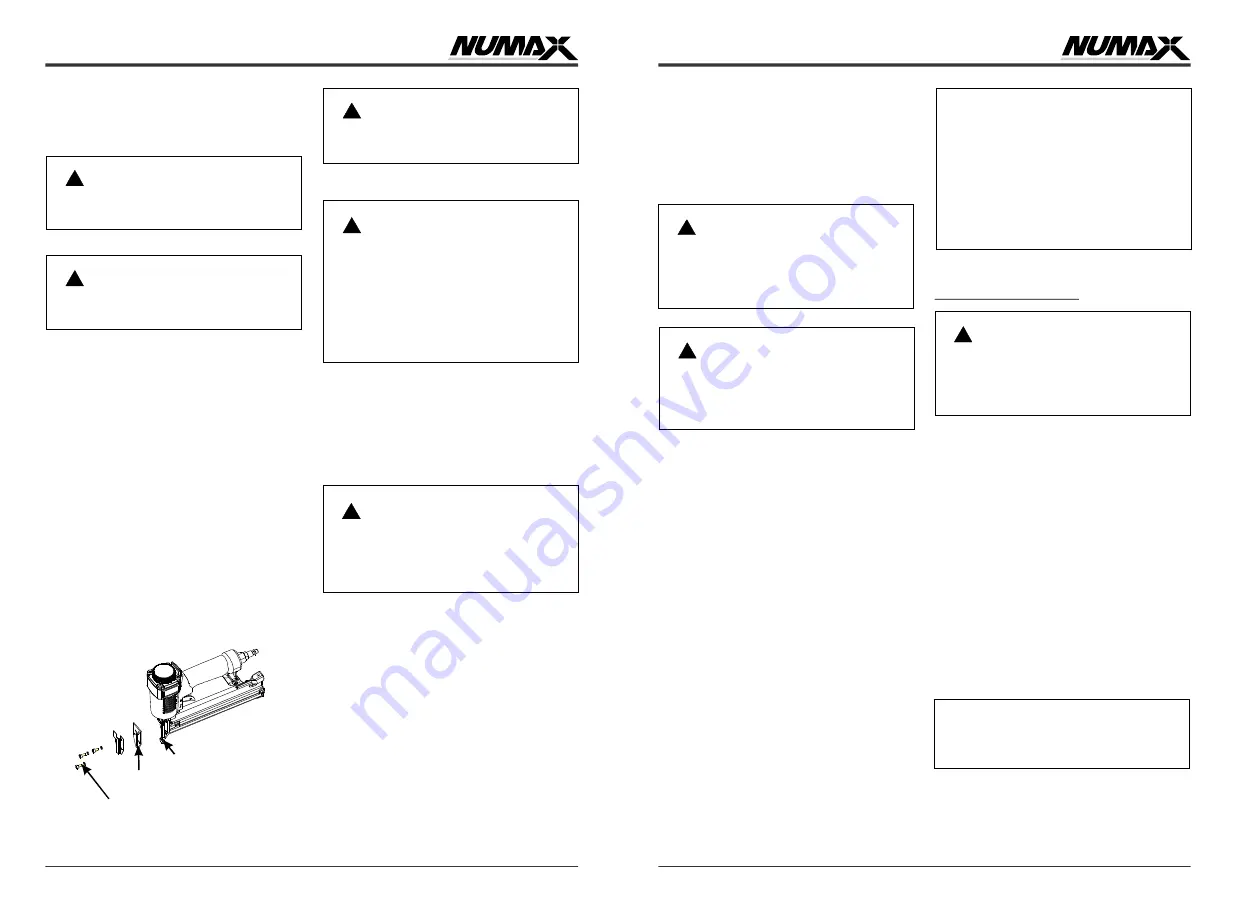

CLEARING JAMS

Disconnect the tool from air source.

Remove fasteners from the tool. Failure to do

so will cause the fasteners to eject from the front

of the tool.

Completely remove the small nose screws(E)

and the top nose plate(F) to reveal the jammed

fastener.

Using caution not to bend or damage the driver

blade, using pliers or a screwdriver if required to

clear the jammed fastener.

Put the nose plate(F) back on the nose(G),

fastening it with the screws(E).

Reconnect the tool to the air source.

Reload the tool with fasteners.

Occasionally, a fastener may become jammed in

the firing mechanism of the tool, making the tool

inoperable. To remove a jammed fastener, follow

the steps below:

⒊

⒋

⒌

⒍

⒎

Nose screws(E)

Nose plate(F)

Nose(G)

1.

2.

HTTP://WWW NUMAXTOOLS COM 1-888-669-5672

.

.

HTTP://WWW NUMAXTOOLS COM 1-888-669-5672

.

.

!

LUBRICATION

Lubricate tool only with specified

lubricants.

CAUTION:

Frequent, but not excessive, lubrication is required

for best performance. Oil for the tool added through

the air line connection add will lubricate the internal

parts. Do not detergent oil or additives as these

lubricants will cause accelerated wear to the seals

and bumpers in the tool, resulting in poor tool

performance and frequent tool maintenance.