11

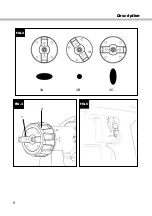

Fig. 3 B = circular jet

Fig. 3 C = vertical fat jet

The spray pattern indication can be found on the front part of the sprayer. With the

arrowhead towards the boss on the tip.

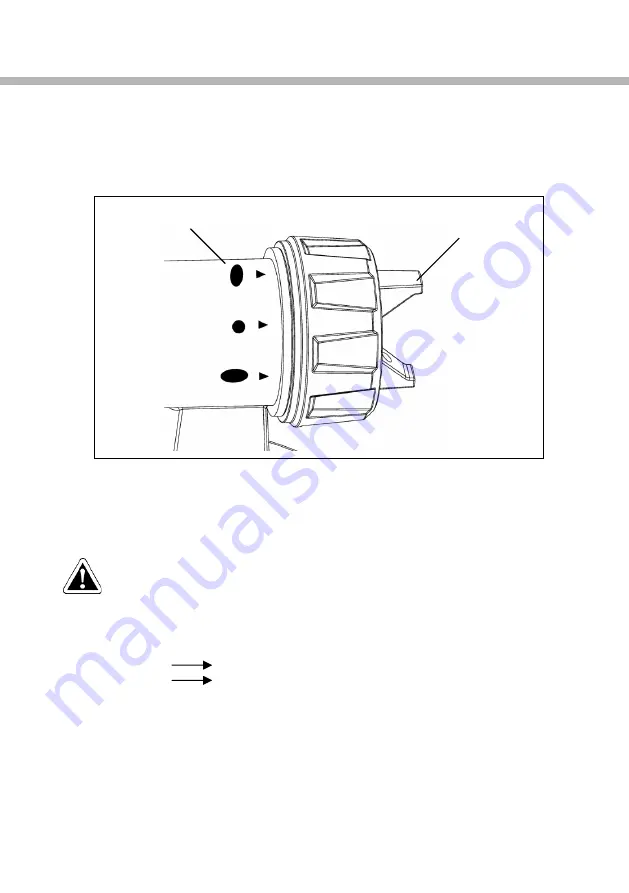

Adjusting the desired Spray Setting (Fig. 4)

With the union nut (2) slightly unscrewed, turn the air cap (1) to the desired spray setting

position. Then tighten the union nut.

WARNING! Danger of injury! Never pull the trigger guard while adjusting

the air cap.

Adjusting the Material Volume (Fig. 5)

Set the material volume by turning the regulator on the trigger guard of the spray gun.

- turn to downside lower material volume

+ turn to upside higher material volume

Spray Technique

■ The spray result depends heavily on the smoothness and cleanliness of the surface

to be sprayed. Therefore the surface should be carefully prepared and kept free of

dust.

■ Cover all surfaces not to be sprayed.

Boss on the tip

Spray pattern indicator

Start-up