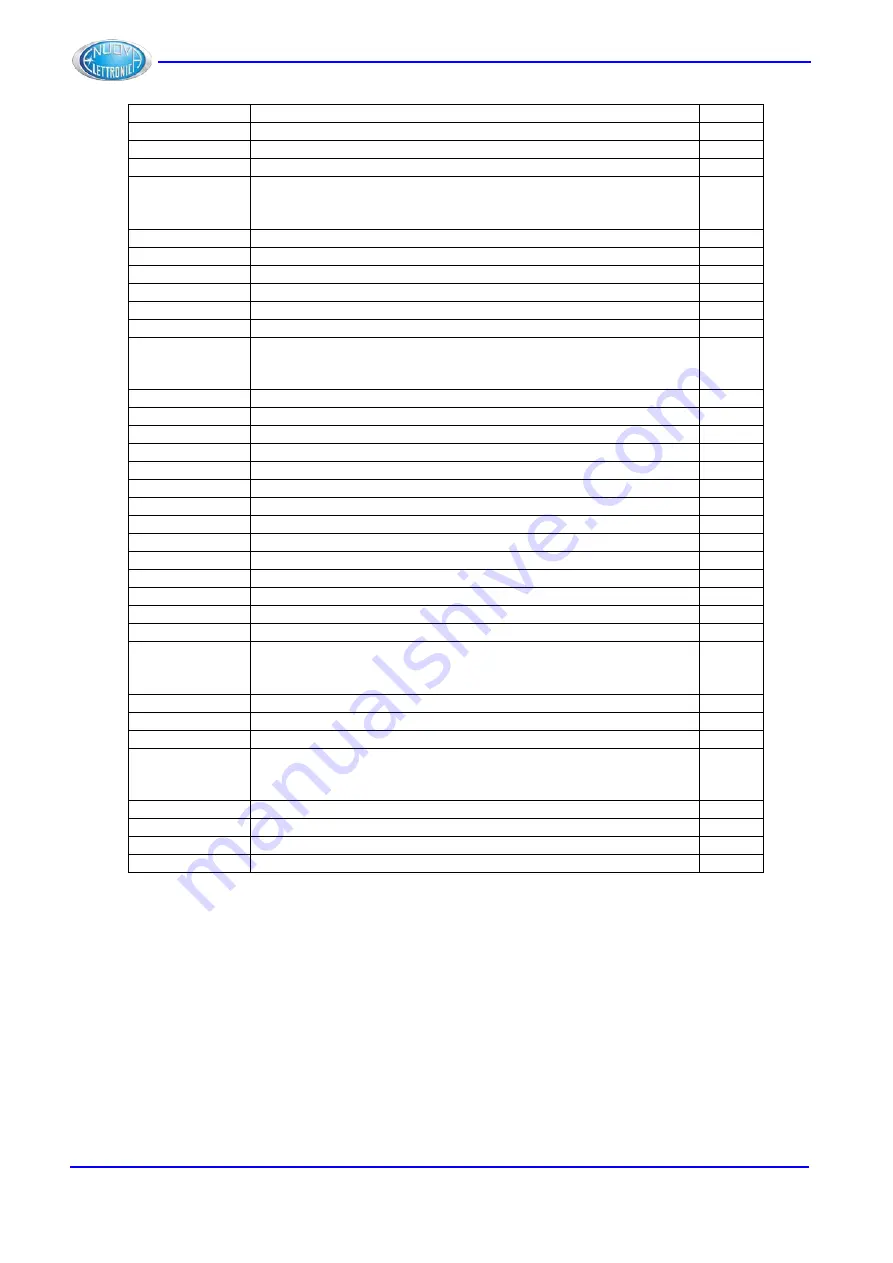

DSP LASER AP with MCS

OUTS5

OUT5/EV 5

OUTS6

OUT6/EV 6

OUTS7

OUT7/EV 7

7

OUTS8

OUT8/EV 8

14

GENERIC INPUTS 24Vcc 7mA

ING1

Upper Tool Holder Command ON/24V

12

ING2

Sheet Edge request button NO

15

ING3

Emergency Reset button NO

ING4

Rear Guard Reset button NO

ING5

Decompression and Stop for Stop Distance NO

16

ING6

Lower Tool Holder Command ON/24V

12

GENERIC OUTPUTS 0,4A 24Vcc

OUTG1

Led integrated in Rear Guard Reset button

OUTG2

Led integrated in Sheet Edge request button

OUTG3

Generic Output1 Programmable from MCS

17

OUTG4

Foot Pedal Control 1 Led active

OUTG5

Generic Output2 Programmable from MCS

17

OUTG6

Led integrated in Emergency Reset button

OUTG7

Signal LOW Speed for CNC

19

OUTG8

Generic Output3 Programmable from MCS

17

OUTG9

Foot Pedal Control 2 Led active

10

OUTG10

Led Upper Tool Holder Open

12

OUTG11

Yellow Blinker

OUTG12

Generic Output4 Programmable from MCS

17, 18

OUTG13

Led Lower Tool Holder Open

12

OUTG14

Output DOWNSTROKE enabling for CNC

20

OUTPUTS with DEDICATED HW FUNCTION

OUTRL1

Output for Relay components to set in emergency

9

OUTRL2

Output for Relay components to set in emergency

9

OUTV

Push-pull output for sheet interception for CNC

21

INPUTS from LINEAR ENCODERS 5V 8/10mA

CHAE1

Input of channel A of the linear encoder of jack Y1

CHBE1

Input of channel B of the linear encoder of jack Y1

CHAE2

Input of channel A of the linear encoder of jack Y2

CHBE2

Input of channel B of the linear encoder of jack Y2

1. When a pulsed input is not used, connect it to the relevant pulsed output.

2. When the rear protection is a mechanical element, signal its opening by means of a

device (e.g.: end-of-stroke) equipped with a NC (normally closed) contact which

connects INP7 to OUTP7 and assign the value “SINGLE” to the programming parameter

B6.

When the rear protection is a Photoelectric Barrier, it is necessary to use its two outputs

(OSSD) to pilot two relays, whose NO (normally open) contacts must be connected: one

to INP7 and OUTP7 and the other to INP8 and OUTP8. In this case, it is necessary to

assign the value “DOUBLE” to the programming parameter B6.

3. The Blanking Modes can be selected even via RS232. To activate this functionality, it is

necessary to assign the value “A CNC” or “B CNC” to the programming parameter B5.

In this case, do not connect INS1 and INS2.

36

DLAM01EN

Summary of Contents for DSP LASER AP

Page 2: ......

Page 4: ......

Page 50: ...DSP LASER AP with MCS Figure 34 44 DLAM01EN...