DSP LASER AP with MCS

11.7. Verification of Low Speed and High Speed

MCS executes a constant control of the speed both in High Speed and in Low Speed.

If, during the downstroke, the speed is higher than allowed (plus a given tolerance), MCS

enters in Emergency. In order to continue to work, a reset of emergency must be executed.

The Low Speed monitored by MCS is that assigned by the parameter A1. If this parameter

is, for example, set to 10, MCS during the downstroke in Low Speed will verify that the

speed reached by the press is never higher than 10mm/s + tolerance, otherwise it will enter

in emergency. The High Speed controlled by MCS, instead, is not assigned by any

parameter, but it is read by MCS during the test of the stop distance. In fact, during the test

of the stop distance, when MCS commands the stop of the machine to measure the

distance, it records even the speed reached by the machine. This speed is the maximum

speed (plus tolerance) the machine can reach in operating mode in High Speed. If this

speed is exceeded, MCS enters in Block condition (every movement is inhibited) and even

the emergency is activated.

Caution:

During the calculation of the stop distance, the maximum allowed press

speed for a safe use of the system is 330 mm/s.

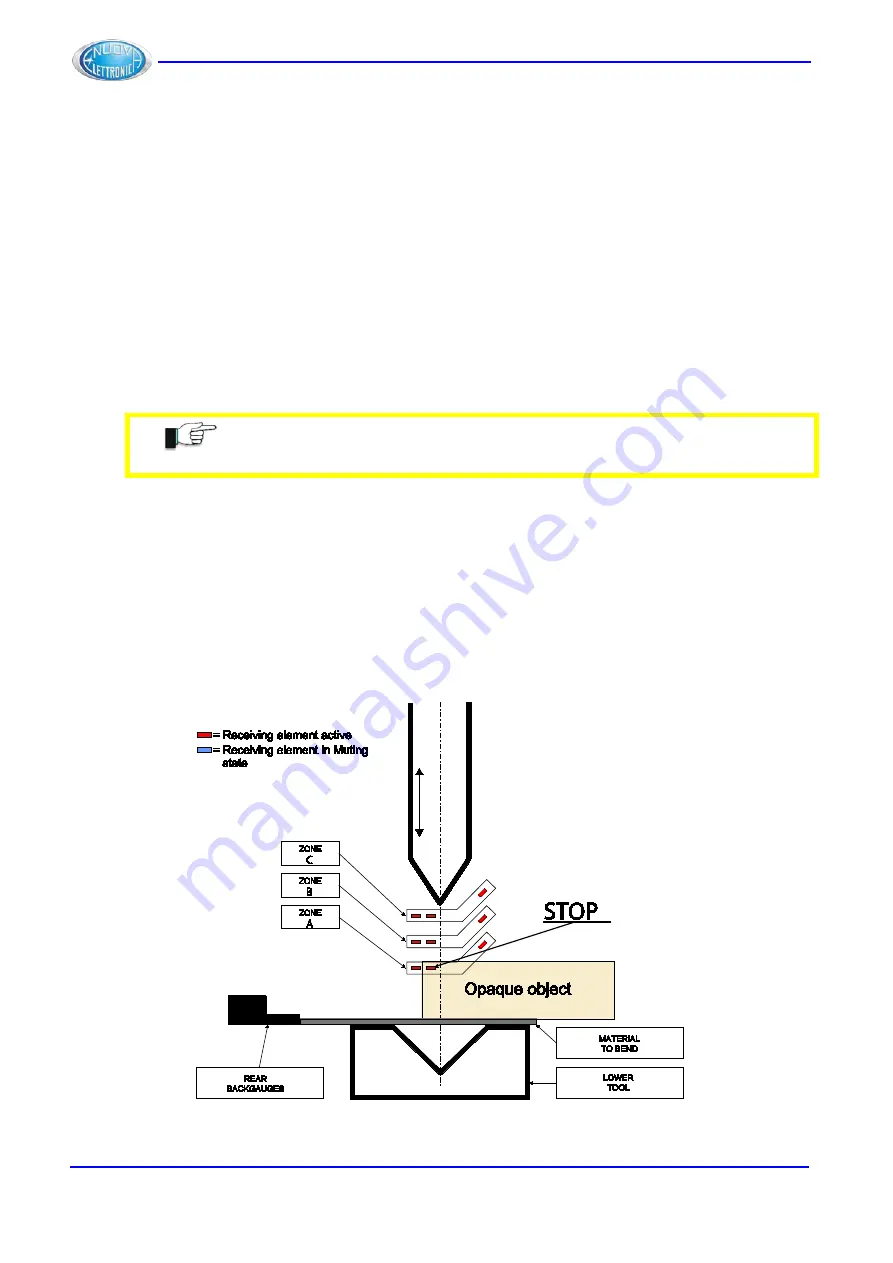

11.8. Speed change point and Automuting

During the downstroke (closing of the press) in High Speed, if an opaque object enters into

the detection area and shades one of the active elements, MCS immediately stops the

machine stroke (Figure 59). In this example, all the elements of all the AREAS (Rear,

Central and Front) are active. The automuting function inhibits the receiving elements

according to what described here below. The auto muting function is active even after

having enabled the Blanking function. If some sensors have been already inhibited by the

Blanking procedure, these remain inhibited.

Figure 59

76

DLAM01EN

Summary of Contents for DSP LASER AP

Page 2: ......

Page 4: ......

Page 50: ...DSP LASER AP with MCS Figure 34 44 DLAM01EN...