DSP LASER AP with MCS

Figure 8

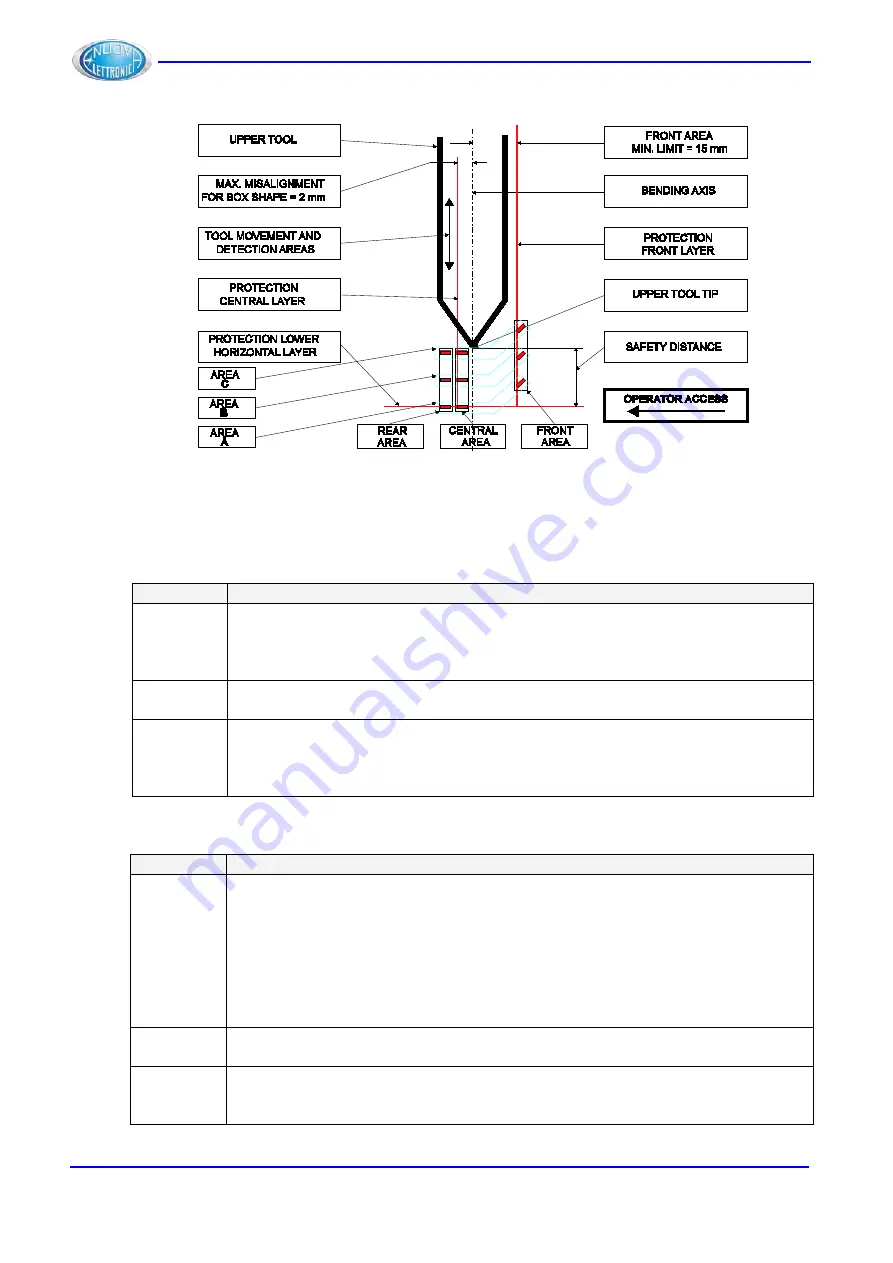

As regards the Blanking function used for bending boxes, the detection area is subdivided

in 3 different areas: a

front area

(towards the operator), a

central area

(under the tip of the

upper tool and sligthly shifted towards the rear part of the press) and a

rear area

(towards

the rear part of the press brake).

Area

Task

Front

Protects the operator’s fingers too close to the working area. Moreover, it

protects against the risk of squashing between the die edge and the tip of the

upper tool.

This area can be inhibited for special machining.

Central

Protects the operator against the squashing between the tip of the upper tool

and the sheet/die.

Rear

Avoid the squashing between the tip of the upper tool and the rear

backgauges.

This area can be inhibited for special machining or if the rear

backgauges are intercepted.

As regards the Automuting function, the detection areas are 3: Area A, Area B and Area C.

Area

Task

Area A

Area A is composed by the 3 lowest sensors: one front sensor, one central

sensor and one rear sensor. The set of sensors of the Area A is that

intercepting first an obstacle during the downstroke. The detection of the sheet

thickness is executed by the central sensor of the Area A.

Note. If the machine Stop Distance, measured by MCS during the test, is less

than 6mm, the Area A is automatically disabled by DSP LASER AP during the

normal operation. It remains, however, active during the verification of the Stop

Distance and the Sheet Edge Acquisition

.

Area B

Area B is composed by the 3 sensors located above the Area A: one front

sensor, one central sensor and one rear sensor.

Area C

Area C is composed by the 3 sensors located above the Area B: one front

sensor, one central sensor and one rear sensor. This set of sensors is the

closest to the tool tip.

14

DLAM01EN

Summary of Contents for DSP LASER AP

Page 2: ......

Page 4: ......

Page 50: ...DSP LASER AP with MCS Figure 34 44 DLAM01EN...