Inner Leg

Adjustment

Crutch Tip

Adjustment

A

Ensure all fasteners (bolts/washers) are securely tightened

and all chair parts have been assembled correctly (Refer back

to Assembly Instructions if needed. Contact Nuprodx, Inc. if

unsure of anything).

B

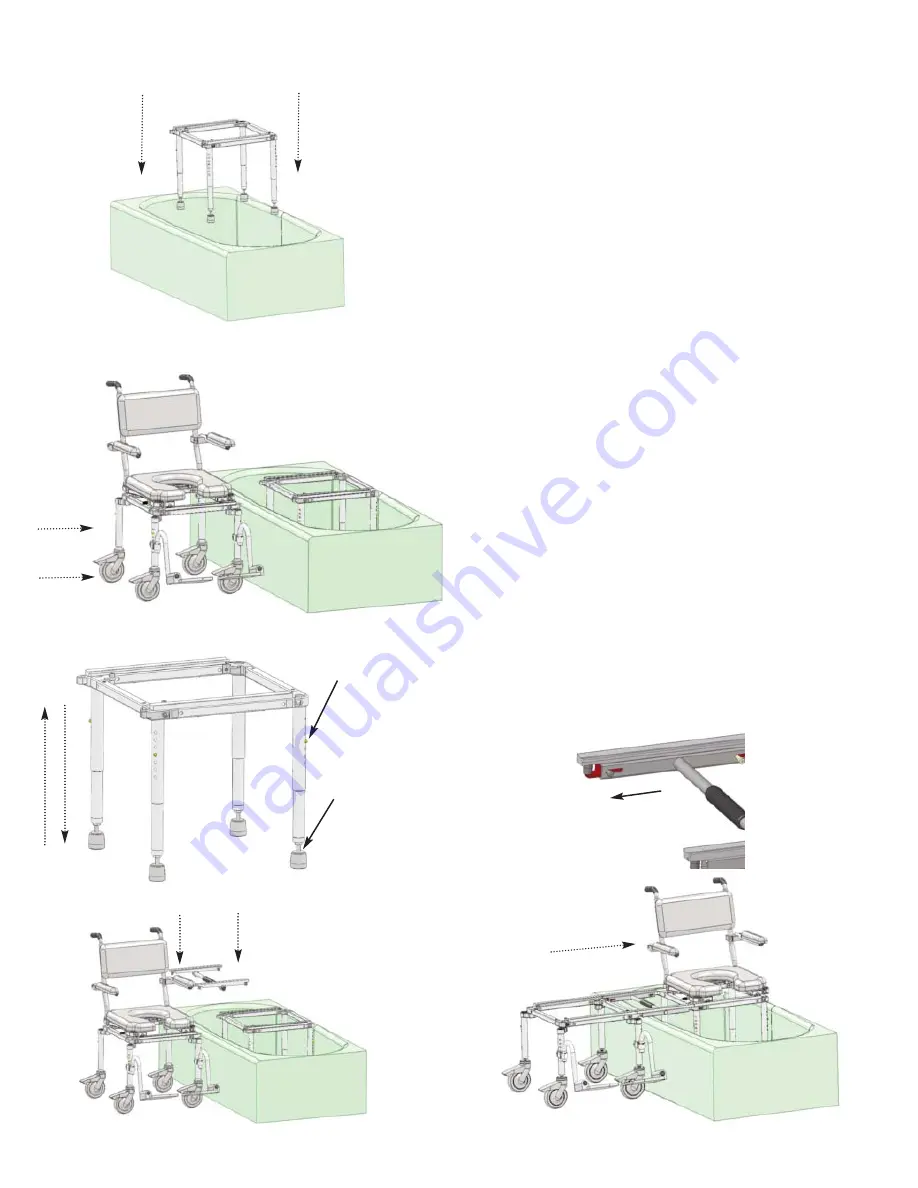

Place the assembled tub section of the slider into the desired

position of the bath tub (Refer to Figure 13).

C

Position the assembled roll-in section of the slider next to the

outside wall of the bath tub (Refer to Figure 14).

D

Adjust the height of the tub section to match the height of the

roll-in section by either adjusting the four inner legs (tub sec-

tion) and/or the adjustable crutch tips (tub section) - Refer to

Figure 15.

E

Insert the connector bridge into the four eyelet holes (Two

located on the roll-in section and two located on the tub sec-

tion) - Refer to Figure 16. Switch the four shoulder screws to

the lock position on the connector bridge (Refer to Figure 17).

F

Release the latch mechanism on the roll-in section and slide

the slider seat assembly onto the tub section, making sure the

latch engages fully and locks in place. If the roll-in section and

tub section are not level in height or out of alignment, the slider

seat assembly will not function correctly and safely. To ensure

the safety of the user, make adjustments to both sections as

needed and retry Step F (Refer to Figure 18).

G

Remove the connector bridge to test the stability of the tub

section. Also, ensure that the slider seat frame is locked into

place and will not remove during use. Once this is complete,

replace the connector bridge and slide the slider seat frame

back to the roll-in section. The connector bridge can then be

removed and the chair is ready for use.

OPERATING INSTRUCTIONS

Figure 13

Figure 15

Figure 16

Figure 14

Figure 17

- PAGE 4 -

Figure 18