4

3. BUILD FRAMEWORK

HD1152A

F

RAMING

BEHIND

DRYWALL

W

ALL

STUDS

35” =

BOTTOM

OF

HOOD

24”

ABOVE

COOKTOP

41” =

BOTTOM

OF

HOOD

30”

ABOVE

COOKTOP

WARNING

!

• When cutting or drilling into wall, do not damage electrical wiring and other hidden utilities.

• When building framework, always follow all applicable construction codes and standards.

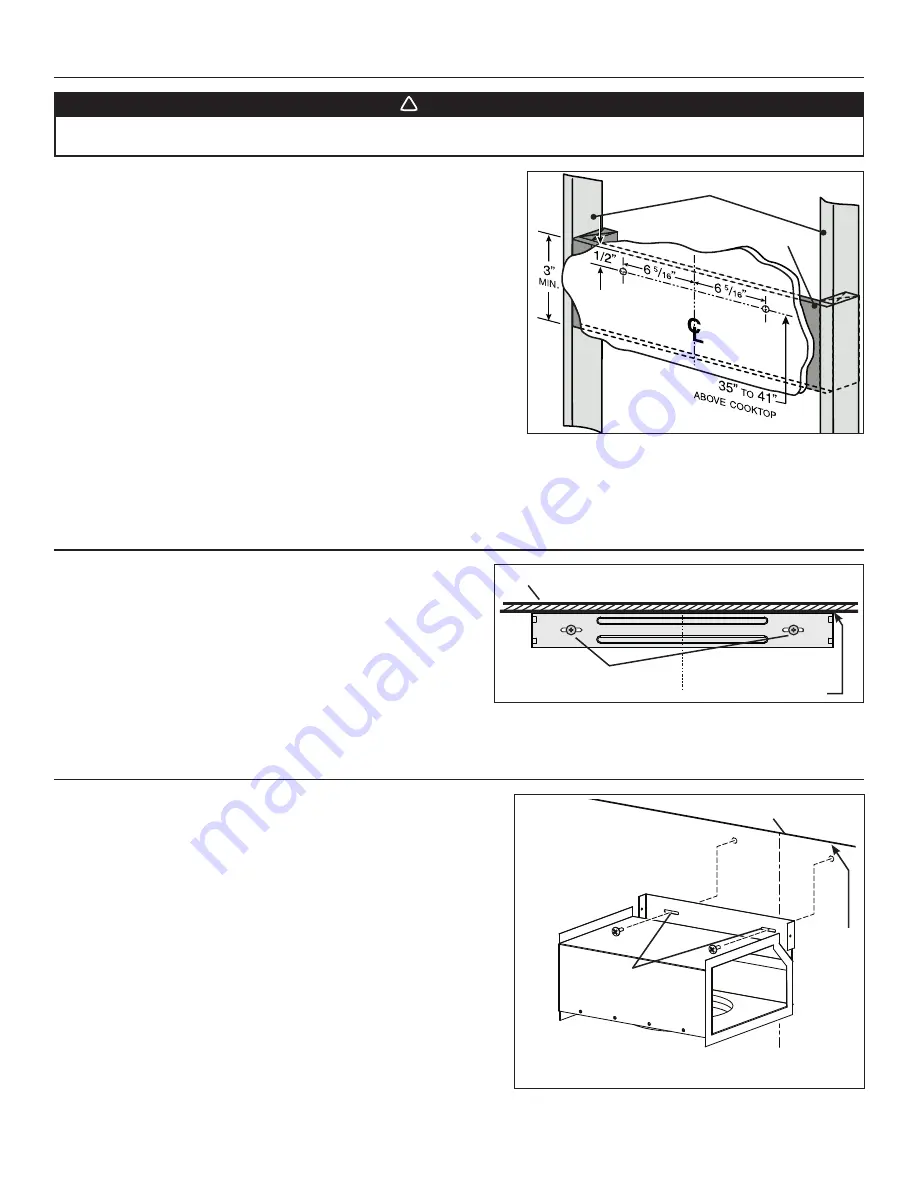

Construct wood wall framing that is even with the surface of wall studs.

Wood wall framing must be at least 1/2” thick and 3” high. Fasten wood wall

framing to wall studs for a solid installation.

Make sure that the height of the framing will allow the retaining screws to be

secured to the framing within the dimensions shown.

After wall surface is finished

, using a level, draw a vertical line up to the

ceiling starting from the center of the planned hood location. Measure and mark

the retaining screw locations using the measurements given in illustration at

right. Insert 2 M4 x 38 Phillips round head mounting screws in wall framing; do

not completely tighten the screws at this time.

4. INSTALL UPPER FLUE MOUNTING BRACKET (DUCTED INSTALLATION ONLY)

Center the upper flue mounting bracket with the center line previously

drawn in step 3 and place it flush with the ceiling. Use the upper flue

mounting bracket as a template to mark the position of its screws.

Secure the upper flue bracket to the wall using 2

M4 x 38 Phillips round

head mounting screws. Make sure that the bracket is tight against the

wall.

5. INSTALL PLENUM (NON-DUCTED INSTALLATION ONLY)

Center the plenum (included in the non-duct kit) with the center line previously

drawn in step 3 and place it flush with the ceiling. Use the plenum mounting

slots as a template to mark the position of its screws.

Secure the plenum to the wall using 2

M4 x 38 Phillips round head

mounting

screws. Make sure that the plenum is tight against the wall.

C

L

HD1154

C

ENTER

OF

INSTALLATION

U

PPER

FLUE

MOUNTING

BRACKET

SLOTS

M

OUNTING

BRACKET

FLUSH

WITH

CEILING

C

EILING

L

C

HD1158

C

EILING

P

LENUM

FLUSH

WITH

CEILING

C

ENTER

OF

INSTALLATION

P

LENUM

MOUNTING

SLOTS