Voyager IV

Nitrox System

Nuvair www.nuvair.com

Page

22

1) Turn on the High Pressure Compressor and allow to run for 1-2 minutes or until Analyzers

stabilize.

2) Crack open the bleed valve on the side of the compressor so that the running HP Compressor

maintains 1500-2000 psi (100-400 bar) outlet pressure. Air will now be flowing past both

Oxygen Analyzers for calibration purposes.

3) Monitor all gauges for proper operating range and check all connections for leaks.(page 20)

4) Calibrate Oxygen Analyzers while the HP Compressor is pumping air. Refer to the Oxygen

Analyzer manual included with the Nitrox System for details. Note that special calibration

procedures may be required when operating at altitudes above sea level.

♦

Permeate Oxygen Analyzer – Turn calibration knob so display reads 20.9%.

a. Fill Oxygen Analyzer – Remove the Flow Adapter Cap

covering the Sensor.

b. Expose the Sensor to ambient air for approximately 15

seconds.

c. Adjust Calibration Knob until Display reading stabilizes at

20.9%.

d. Reinstall the Flow Adapter Cap to the analyzer.

e. The Fill Oxygen Analyzer is now ready for use.

Different settings may be used depending on location,

so verify your actual ambient conditions and refer to

the Oxygen Analyzer manual for details.

5) Turn on the LP Compressor and increase the pressure to

a minimum of 90 psi.

6) Allow the Compressors to run for a 10 Minute warm up period for

the Membranes to warm up and stabilize. Check the Heater

Temperature Gauge to verify air temperature rises and is between 105-120 ºF (40-49 ºC).

7) Turn off LP Compressor and Re-Calibrate The Fill Analyzer..

8) Now that the System Temperature has stabilized You must Re-Calibrate the Fill O

2

Sensors.

See Step 4a above.

The Oxygen Analyzers may require re-calibration after 10-20 minutes of operation due to

humidity and temperature change effects on the Sensor. To recalibrate, turn off the LP Feed

Air and follow calibration instructions.

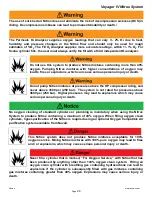

Sensor Cap

Removed

Calibration

Knob

Compressor Controls

Fill Oxygen Analyzer

Calibration Knob

Permeate Oxygen Analyzer

Provides Rough Reading

Fill Oxygen Analyzer

Provides Precise Reading

On/Off Knob for

HP Compressor