Voyager IV

Nitrox System

Nuvair www.nuvair.com

Page

31

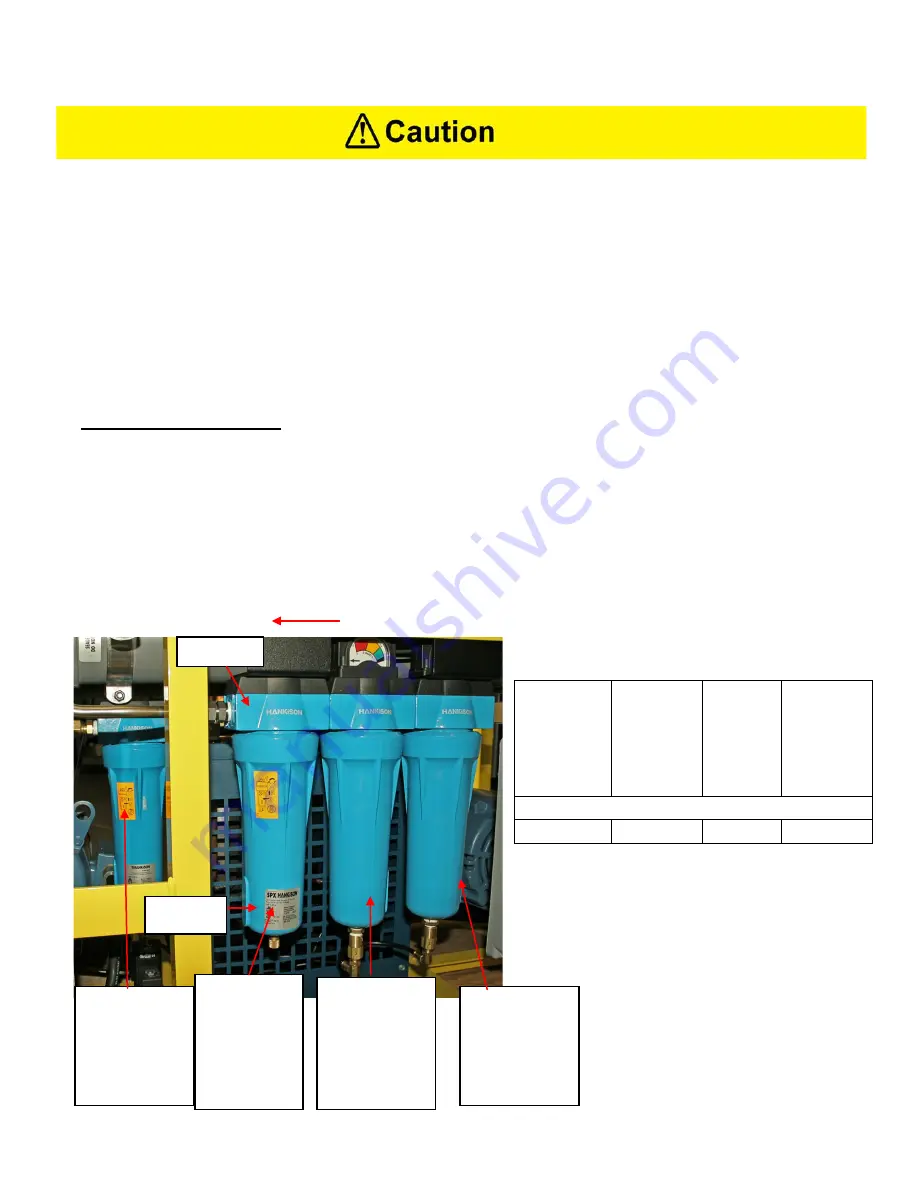

17.4 LP Feed Air Filtration

Special attention needs to be given to the arrangement of the four LP Feed Air Filtration

Elements and Bowls. Properly reinstall each Element and Bowl to the correct Housing.

Improper sequence can cause damage to downstream components.

The use of Grade D or better feed air is critical to prevent the passing of any residual oil vapor into

the Membrane System. Four stages of Hankison LP filtration are used to produce Grade D air:

1) Coalescing Filter

2) Coalescing & Water/Oil Vapor Removal to 1 Particulate micron

3) Coalescing & Water/Oil Vapor Removal to 0.01 Particulate micron

4) Final Stage - Oil Vapor Removal to 0.003 PPM

LP Filtration Inspection

Open each Filter and inspect as follows:

1) Inspect Bowl for the presence of moisture. A high level of moisture build-up in the HF11-24 or

HF7-24 Filter indicates improper operation of auto-drain floats. Evidence of any moisture in the

HF1=24 Filter indicates air is not cooling properly and moisture is not properly being removed.

Check HF1 canister weekly for moisture. Moisture indicates possible refrigerated dryer problem.

Excess moisture will prevent the final filter from operating properly and can lead to damage of the

membrane.

HF1-24

HF5-24

HF7-24

HF11-24

Oil

Coalescing Particle

Vapor

&Water/Oil

&

Coalescing

Removal

Vapor

Moisture

Removal

Removal

Replacement Element Part Number

E1-24

E5-24

E7-24

E11-24

Air Flow

HF5-24Filters

with Auto-

Drain Float &

Liquid Level/

Service

Indicators

Housing

HF1-24

Filter with

Manual

Drain –

Should not

Contain

Moisture

HF7-24 Filter

with Auto-

Drain Float &

Liquid Level

Indicator

Bowl

HF11-24

Filter with

Auto-Drain

Float & Liquid

Level

Indicator