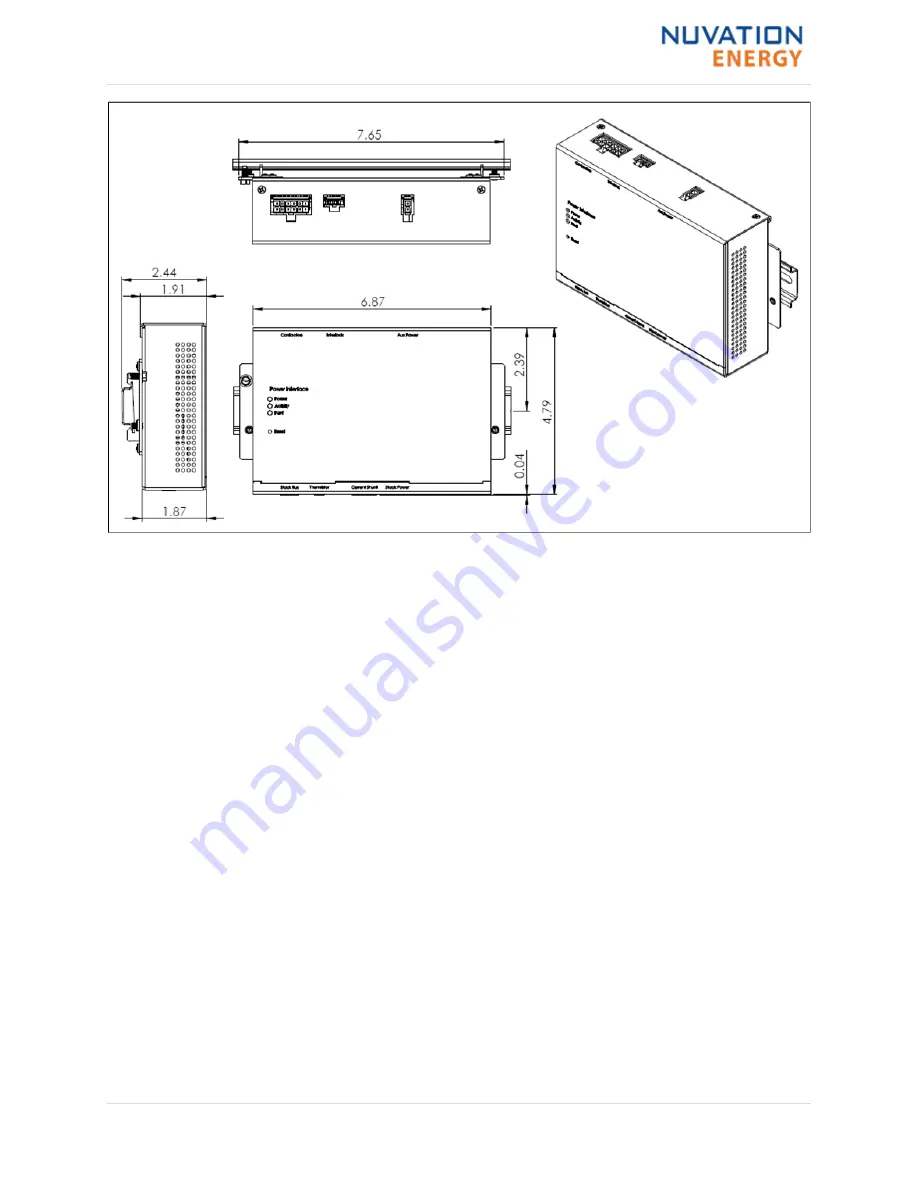

Figure 11. Mechanical Drawing of Power Interface

5.3. Electrical Connections

The Power Interface module has seven connectors. Each connector is described in the following

sections in detail.

5.3.1. Contactors

The Contactor connector is a 12-pin Mini-Fit® Jr. Molex connector. This interface is used to provide

or select contactor coil operating power, either from an external power supply (40V max), or from

a loop-back connection from the BMS internal 24V (nominal) source.

The Contactors connector also connects to up to four (4) external contactor coils. Each output is

capable of sourcing a maximum of 2.8A continuously. If coil operating power is provided from an

external power source, the sum of all four output currents must not exceed 5A continuous. If coil

operating power is provided from the internal power source, the sum of all four output currents

must not exceed 2.8A or 2.9A minus 31.7mA per Cell Interface connected in the system,

whichever is lower.

Coil high-side drive and return outputs are provided at the connector. The return is referenced to

the Power Interface chassis. Contactor coil back-EMF is internally clamped at 40V.

Connect up to four (4) high-current contactor coils to this connector.

Installation Guide - 2018-10-08, Rev. 2.0

24