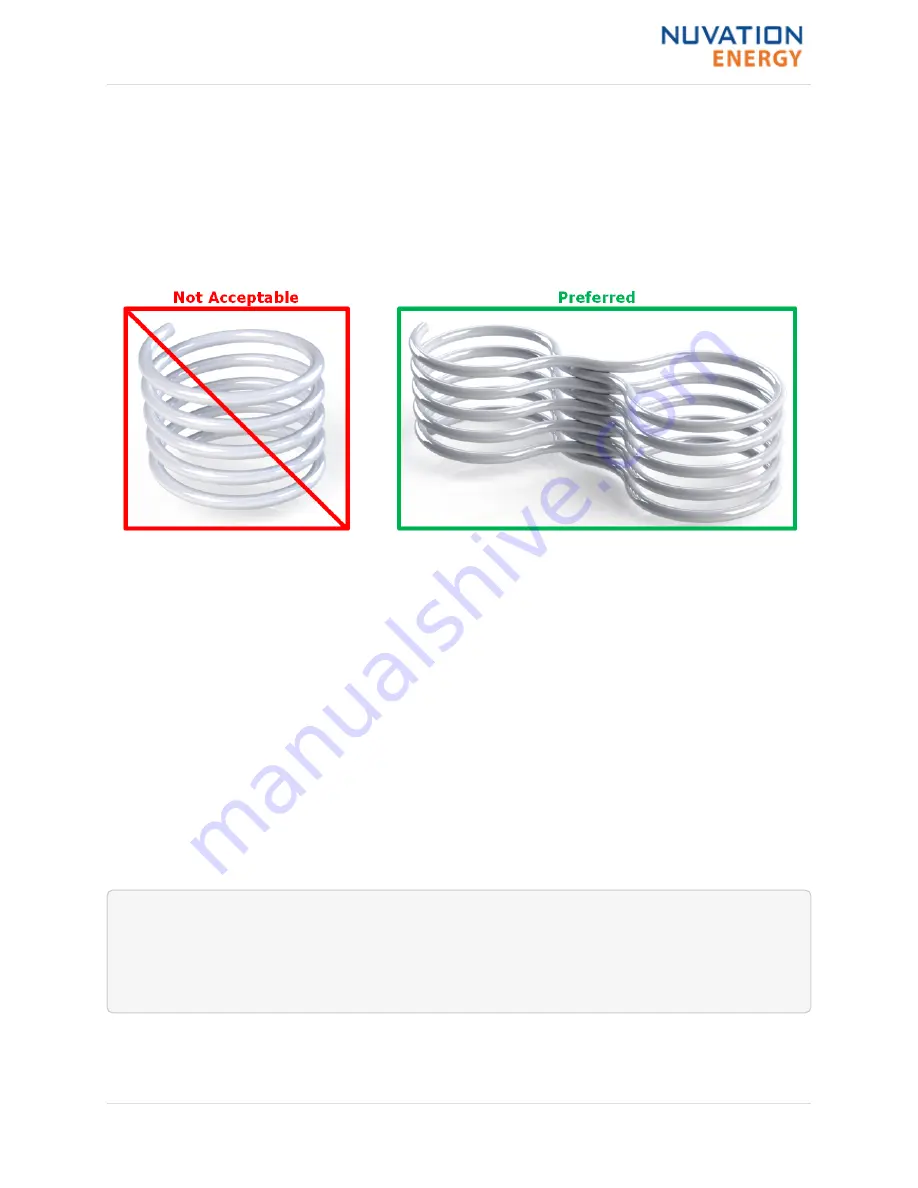

If reducing the cable length is not feasible or if there is no time to physically modify the lengths, a

common solution is to wrap the excess cable length in a coil and fasten the wire loop in the

cabinet. This basic tactic has the undesirable effect of creating an air-core transformer which will

couple EMI into the cable extremely well.

The best solution to cable length management is to bundle the excess length in a figure-8 pattern.

This prevents the bundle from turning into an air-core transformer since the direction of current in

one side of the figure-8 turns opposite to the current in the other side. It is recommended to use

the figure-8 method if physically reducing the cable length is not possible.

Figure 15. Excess Cable Management Examples

6.3. System Noise

High-power inverters generate a lot of system noise, especially on the DC bus. This is due to the

industry standards for AC harmonics and EMC on the grid-side which require the DC bus to help

filter out the harmful emissions. Unfortunately, that means the battery cells, and the Nuvation

BMS, experience extreme levels of noise.

The most harmful emissions on the DC bus are between the DC bus and earth. This is due to the

slew-rate of the switching devices implemented in the inverter (usually IGBTs). The slew-rate is

impacted by a many elements, and the emissions can be minimized by carefully grounding the

installation so that the return-path for the high-frequency switching noise can be kept small.

The Nuvation BMS has various faults and informative registers to determine if the system has a

high level of noise that is impacting the Nuvation BMS.

The communication faults are:

sc_fault_linkbus_wdt.trig

sc_fault_stackbus_rxwdt.trig

sc_fault_stackbus_txwdt.trig

sc_fault_pi_afe_wdt.trig

sc_fault_controller_wdt.trig

The informative communication error registers are:

Installation Guide - 2018-10-08, Rev. 2.0

34