17

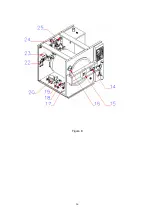

5.16. Replacing Locking Bobbin ( see Figure 7 & Figure 9)

•

Remove the flywheel handles (4).

•

Remove the lid protection cover (3) by removing its 4 screws.

•

Take the locking bobbin out by removing the bobbin (14) connection screws.

•

Separate the locking bobbin (14) electrical connection cables by cutting their welding points.

•

Take the pin on the locking bobbin and fix it onto the new bobbin.

•

Mount the new bobbin.

•

Connect the electrical connection cables by welding them carefully.

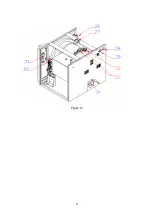

5.17. Replacing Locking Switch ( see figure 10)

•

Disconnect the locking switch (30) terminal connections.

•

Take the locking switch out by removing the locking switch connection nuts.

•

Mount the new locking switch and make the necessary electrical connections carefully according to

the electrical circuit diagram (figure 3 or Figure 4).

•

Adjust the switching length carefully.

5.18. Cleaning The Sterilizatior Chamber Filter ( see Figure 8 & Figure 11)

•

Take the shelf carrier (12) and the heater protection sheet (11) out by removing the shelf carrier

mounting screws (34) in the sterilization chamber.

•

Take the filter (36) out which is placed on the bottom of the chamber by removing the water inlet

record (35) with a wrench.

•

Clean the filter pores and re-mount it.

5.19. Replacing Pressure Switch ( see Figure 10)

•

Disconnect the cable connections of pressure switch terminals

•

Remove the pressure switch

•

Put some liquid gasket to female connectors of the new pressure switch to ensure that there is no

leakage and mount the new pressure switch

•

Make the electrical connections carefully according to the electrical circuit diagram (Figure 3 or

Figure 4)

•

Adjust the minimum pressure switch (33) by turning the red adjusting switch counter-clockwise or

adjust the maximum pressure switch (32) by turning the red adjusting switch clockwise.

Summary of Contents for OT 020

Page 19: ...18 SECTION 6 DIAGRAMS AND DRAWINGS ...

Page 20: ...19 6 1 ELECTRICAL CIRCUIT DIAGRAM OT 020 Figure 3 ...

Page 21: ...20 6 2 ELECTRICAL CIRCUIT DIAGRAM OT 020V Figure 4 ...

Page 22: ...21 6 3 WATER AND STEAM UNIT DIAGRAMS Figure 5 OT 020 flow diagram ...

Page 23: ...22 Figure 6 OT 020V flow diagram ...

Page 24: ...23 SECTION 7 SPARE PART LIST ...

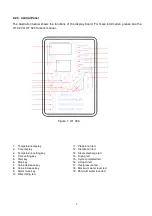

Page 25: ...24 Figure 7 ...

Page 26: ...25 Figure 8 ...

Page 27: ...26 Figure 9 ...

Page 28: ...27 Figure 10 ...

Page 29: ...28 Figure 11 ...